Understanding Kovar Alloy Properties and Machining Challenges

If you’re considering kovar machining services, it’s important to first understand what makes this alloy special and why it requires expert handling. Kovar is a unique iron-nickel-cobalt (Fe-Ni-Co) alloy prized for its stable thermal expansion, which closely matches that of borosilicate glass. This makes it ideal for hermetic sealing components used in electronics, aerospace, and medical devices.

Core Composition and Characteristics

Kovar typically contains about 29% nickel, 17% cobalt, and the rest iron. This specific blend gives it these key traits:

- Low thermal expansion: Maintains dimensional stability under temperature changes.

- Excellent corrosion resistance: Suitable for harsh environments.

- Good mechanical strength: Can withstand stress in high-performance applications.

- Superior glass-to-metal sealing ability: Ensures airtight, reliable seals in telecom and medical electronics.

Key Machining Challenges and Solutions

Despite its great properties, Kovar isn’t the easiest metal to machine. Some challenges include:

- Hardness and toughness: Can wear down cutting tools quickly.

- Burr formation: Requires precision to prevent rough edges.

- Thermal sensitivity: Cutting generates heat that might cause warping or distortion.

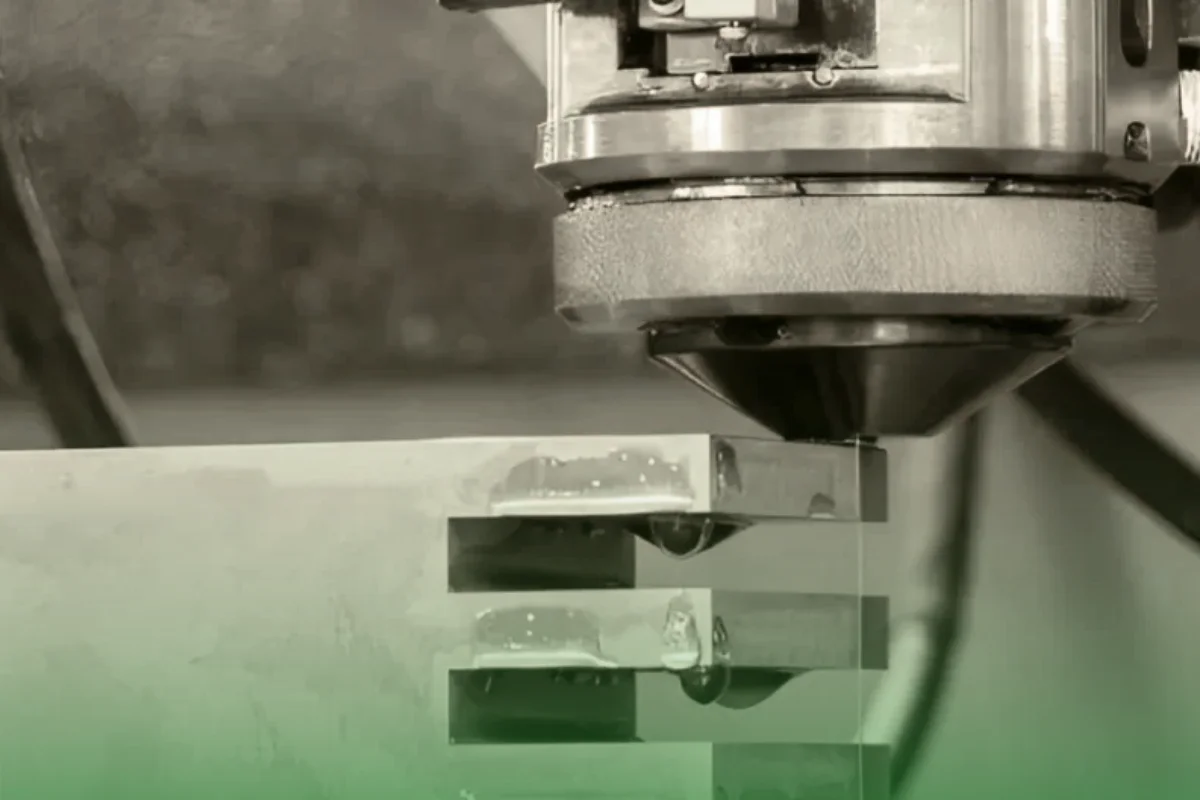

At XTJ Precision Mfg, we tackle these challenges by using specialized CNC milling and Swiss machining techniques. Our advanced tooling reduces tool wear, while controlled heat treatment and coolant systems keep the workpiece stable. This helps achieve competitive CNC tolerances, ensuring every part fits perfectly in assemblies.

Benefits of Factory Direct Pricing

Choosing factory direct Kovar machining services offers clear cost advantages:

- Lower material and setup costs: No middlemen or added fees.

- Transparent pricing: Understand exactly what you’re paying for.

- Better scalability: Whether you need a custom Kovar prototype or high-volume production, factory pricing adapts to your needs.

This approach lets you maximize return on investment, balancing quality and price effectively. For more insights into cost drivers, check out our guide on how much is the cost per CNC machining part.

Understanding these aspects upfront helps you get the best results with Kovar alloy machining while staying within budget.

XTJ Precision Mfg Kovar Machining Capabilities

At XTJ Precision Mfg, we specialize in Kovar alloy CNC milling and precision Fe-Ni-Co machining tailored to tight U.S. manufacturing standards. Our advanced CNC and Swiss machining processes ensure every part meets demanding specifications, from tiny hermetic sealing components to larger thermal stable alloy parts.

Advanced CNC and Swiss Machining Processes

- High-precision CNC mills and Swiss machines handle Kovar’s unique properties, delivering consistent accuracy and smooth finishes.

- Capable of working with complex geometries needed for aerospace Kovar lead frames and electronics glass-to-metal seals.

- Our machines maintain competitive CNC tolerances Kovar clients expect, reducing post-processing time.

Material Handling and Heat Treatment

- We carefully manage Kovar’s core composition during machining to prevent warping or stress.

- Heat treatment processes ensure dimensional stability and maintain Kovar’s low expansion metal fabrication benefits.

- This minimizes machining challenges and improves final product performance in demanding environments.

Scalability from Prototyping to High Volume Runs

- Whether you need custom Kovar prototyping China or large production runs, XTJ offers flexible application scalability.

- Quick prototype turnaround allows for early testing of hermetic sealing components and other precision parts.

- Full-scale production keeps costs down, providing factory direct Kovar quotes that give best price options for U.S. customers.

With XTJ Precision Mfg, you get reliable, high-quality Kovar machining services at factory prices geared specifically for the U.S. market.

Breaking Down Factory Pricing for Kovar Machining

When it comes to factory direct Kovar machining pricing, there are a few key cost drivers to keep in mind:

- Material Costs: Kovar alloy is a specialty low expansion metal, so its price is higher than common metals. Bulk buying helps reduce costs, which is why factory prices tend to be more competitive.

- Setup and Tooling: Machining Kovar requires precise CNC milling setups and sometimes specialized tooling to handle its thermal stable alloy properties. Initial setup costs can be significant, especially for custom parts or prototypes.

- Production Volume: Larger orders spread out tooling and setup costs, lowering the per-piece price. XTJ offers scalable runs from prototyping to high volume, meaning you pay less as you order more.

XTJ Precision Mfg uses a transparent pricing model with clear quotes upfront. For example, a small batch of hermetic sealing components might include a setup fee plus material and machining time, while a larger production run benefits from reduced unit costs. This approach helps customers clearly see where their investment is going.

Choosing XTJ also means better return on investment due to:

- High yield rates from tight CNC tolerances on Kovar parts, reducing waste and rework

- Efficient workflow that shortens lead times and shipping costs

- Factory direct quotes cut out middlemen, saving you money and improving delivery reliability

For more on managing machining costs and getting the best quote, check out our guide on how to reduce CNC machining costs.

Real World Applications of XTJ Kovar Machining Services

At XTJ Precision Mfg, our Kovar machining services are designed to meet the tough demands of several critical industries in the US market. Here’s where our expertise truly shines:

Aerospace and Defense Components

Kovar’s unique thermal expansion properties make it ideal for aerospace parts like lead frames and connectors that must endure extreme temperature shifts without losing integrity. We machine precision Fe-Ni-Co components that comply with strict aerospace standards, ensuring reliability and durability for defense applications.

Electronics and Telecom Hermetic Packaging

Hermetic sealing components are key in electronics and telecom equipment to protect sensitive circuits and glass-to-metal seals. XTJ’s CNC milling of Kovar alloy provides stable, thermal-compatible parts that maintain airtight seals, essential for hermetic packaging that demands high precision and consistency.

Medical and Optics Custom Solutions

We also deliver custom Kovar prototyping for medical devices and optical systems where thermal stability is critical. Our precision machining supports tight tolerance requirements for low expansion metal fabrication used in medical instruments and optics housings, enabling high-quality, reliable performance.

These applications benefit from XTJ’s scalable manufacturing – from small prototype batches to high-volume production runs. Whether you are in aerospace, telecom, or medical industries, our factory direct Kovar machining services offer competitive pricing without compromising quality or delivery times.

Quality Assurance and Trust Factors for XTJ Kovar Projects

When it comes to Kovar machining services, quality is non-negotiable. At XTJ Precision Mfg, we prioritize delivering parts that meet strict industry standards, ensuring every component performs perfectly in demanding applications.

Certifications and Compliance Standards

We maintain full compliance with key certifications relevant to aerospace, medical, and electronics sectors. These include ISO 9001 for quality management and specific material certifications for Fe-Ni-Co alloys like Kovar. This helps guarantee the reliability and traceability of every part we machine.

Risk Mitigation and Inspection Methods

XTJ employs rigorous inspection protocols, such as 3D coordinate measuring machines (CMM) and optical inspection, to catch any deviations early. Our skilled operators also monitor thermal processing and heat treatments closely to maintain the low expansion properties Kovar is known for. This approach reduces scrap rates and improves overall yield, saving time and money for our clients.

Client Testimonials and Eco Friendly Practices

Our long-term partnerships across the US speak for themselves. Customers consistently appreciate our transparent communication, precision tolerances, and on-time delivery. Plus, XTJ is committed to eco-friendly manufacturing. We minimize waste during CNC milling and embrace energy-efficient processes to lower our carbon footprint while maintaining top-tier quality.

For companies looking to balance cost, quality, and sustainability in Kovar alloy CNC milling, XTJ Precision Mfg stands out as a trusted partner. Explore our factory direct Kovar quotes and see how we can provide competitive CNC tolerances with confidence.

For more insights on our machining capabilities, check out our CNC turning services and 5-axis CNC machining pages.