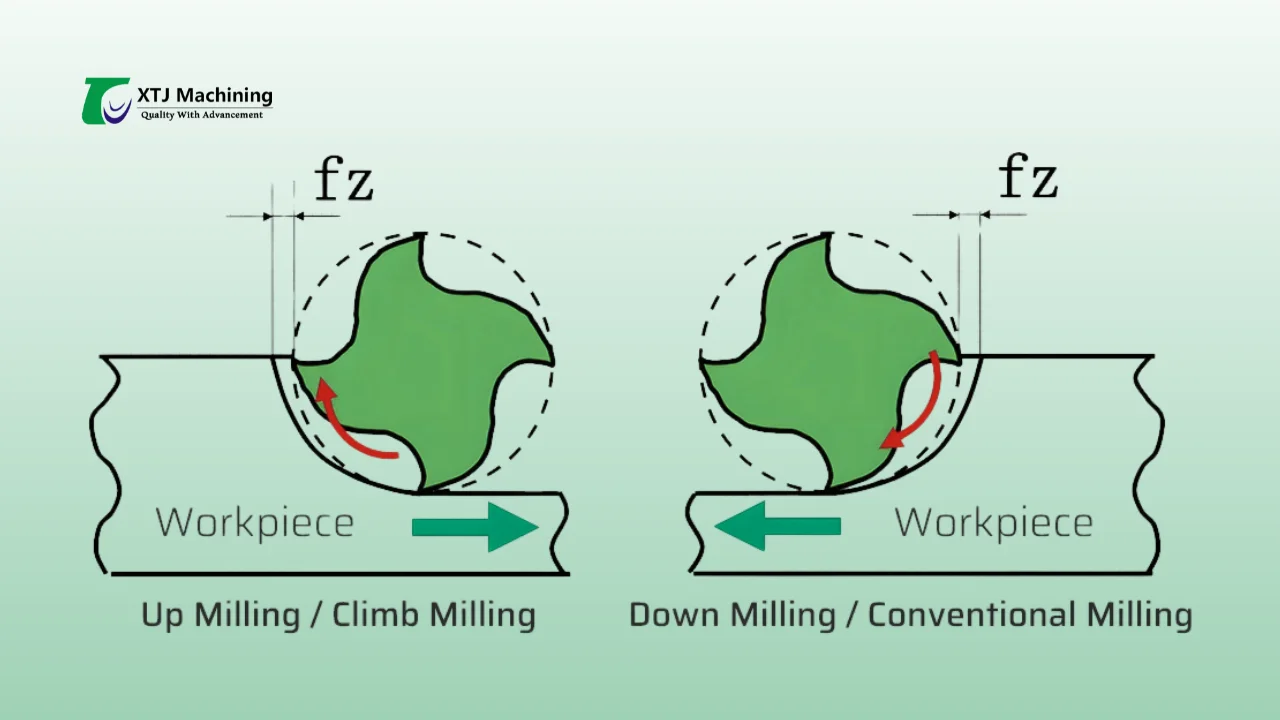

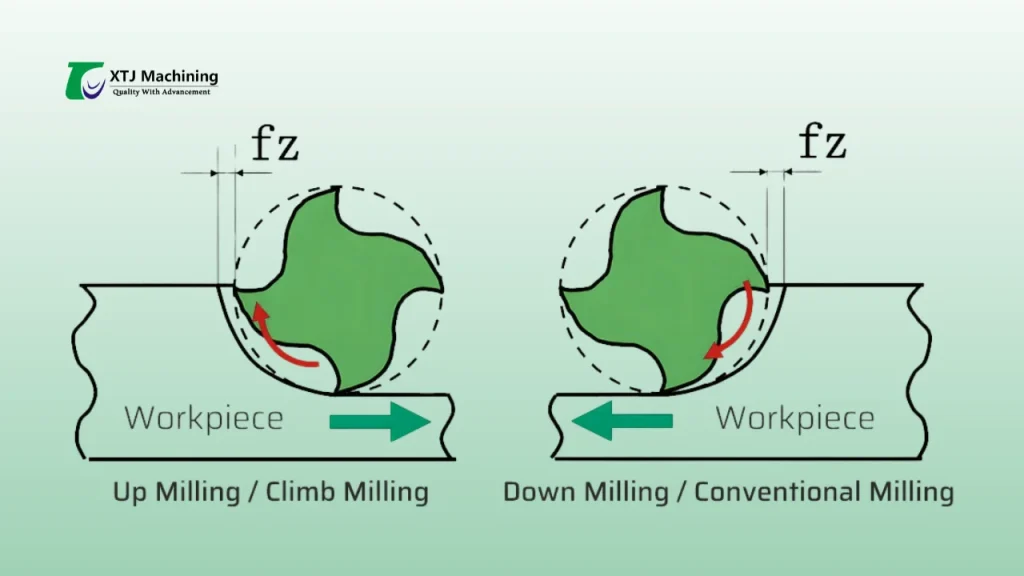

The Fundamentals How Climb and Conventional Milling Work

Milling is a core machining process where a rotating cutting tool removes material from a workpiece. The direction the cutter rotates relative to the feed movement defines two primary methods: conventional milling and climb milling.

Core Mechanics of Conventional Milling (Up Milling)

In conventional milling (also called up milling), the cutter rotates against the direction of the feed. Here’s how it works:

- The cutting edge begins machining the material at zero chip thickness and increases throughout the cut.

- This gradual engagement means the tool starts by rubbing against the workpiece, creating higher friction and heat.

- The chip thickness increases as the cutter rotates, letting the tool “plow” through material.

- Cutting forces tend to push the workpiece upward and away from the cutter.

- This leads to more tool deflection and a rougher surface finish but can be safer on older machines with backlash issues.

Core Mechanics of Climb Milling (Down Milling)

In climb milling (also called down milling), the cutter rotates with the feed direction:

- The cutter engages with the workpiece at maximum chip thickness and the chip thickness decreases to zero as the cut finishes.

- This results in less rubbing and heat generation because the tool bites into the material from the start.

- The cutting forces push the workpiece downward and toward the table, enhancing stability.

- Climb milling generally offers better surface finishes and longer tool life but requires machines with minimal backlash.

Key Comparison Table

| Aspect | Conventional Milling (Up Milling) | Climb Milling (Down Milling) |

|---|---|---|

| Direction of Cut | Cutter rotates against feed | Cutter rotates with feed |

| Chip Thickness | Starts at zero, increases | Starts max, decreases |

| Cutting Force Vector | Pushes workpiece upward/away | Pushes workpiece downward/toward |

| Tool Deflection | Higher | Lower |

| Surface Finish | Rougher | Smoother |

| Heat Generation | More rubbing, higher | Less rubbing, cooler cutting |

| Machine Backlash Risk | Lower sensitivity | Needs low backlash for accuracy |

Understanding these core differences is key to choosing the right milling strategy, especially when considering CNC machining precision, tool wear, and surface quality.

Pros and Cons A Head-to-Head Comparison

Advantages and Drawbacks of Conventional Milling

Advantages:

- Better for older machines without backlash compensation

- Easier to control tool deflection since cutting force pushes tool away from the part

- Safer for thin-walled or delicate parts prone to pulling in

- Good for roughing operations and lower cutting speeds

Drawbacks:

- Higher tool wear due to rubbing at the start of the cut

- Poorer surface finish compared to climb milling

- More heat generated, which can affect tool life

- Chip evacuation is less efficient because chips move against the cutter rotation

Advantages and Drawbacks of Climb Milling

Advantages:

- Produces better surface finish due to gradual chip thickness reduction

- Lower cutting forces, reducing tool wear and extending end mill tool life

- Chips evacuate cleaner as they move with the cutter rotation

- Ideal for CNC machines with backlash compensation for smoother cuts

Drawbacks:

- Can pull the workpiece into the cutter, risking damage without proper fixturing

- Not recommended for machines with backlash or worn lead screws

- Requires precise speed and feed settings, narrow RPM tolerance

- Slightly more complex setup and monitoring to avoid machining chatter

Pros Cons Table Including RPM Tolerance and Chip Evacuation

| Feature | Conventional Milling | Climb Milling |

|---|---|---|

| Tool Wear | Higher due to rubbing | Lower, smoother cut |

| Surface Finish | Rougher | Smoother |

| Chip Evacuation | Less efficient, against rotation | More efficient, with rotation |

| Machine Requirements | Works on older machines | Needs backlash compensation |

| Cutting Forces | Pushes tool away from work | Pulls tool into work |

| RPM Tolerance | Wider tolerance, forgiving | Narrow tolerance, precise |

| Setup Complexity | Easier setup | Requires precise control |

This comparison helps decide which milling approach fits your shop’s machines and parts best.

When to Use Each Practical Applications and Best Practices

Scenarios for Conventional Milling

Conventional milling, or up milling, works best when you’re dealing with older machines or setups with backlash issues. Since the cutter starts with a thin chip and gradually increases thickness, it’s gentler on the tool and the machine’s drive system. That makes it a solid choice for:

- Rough milling on cast iron or tough metals where tool deflection could be a problem

- Machines without perfect backlash compensation in CNC controls

- Materials prone to work hardening like stainless steel

- Situations where surface finish is less critical, but tool stability is a priority

Scenarios for Climb Milling

Climb milling, also known as down milling, shines in modern CNC machines with minimal backlash and rigid setups. It offers better surface finish and longer tool life because the cutting forces tend to pull the tool into the material, reducing chatter and vibration. Use climb milling when you need:

- Finishing cuts on aluminum, softer metals, and plastics like acrylic

- Higher feed rates and speeds for improved efficiency

- Cleaner chip evacuation since the chips are thinner at the start and thicker at the end

- Reduced tool wear on tough high-speed machining jobs

Hybrid Strategies Combining Both Techniques with Real XTJ Case Study

At XTJ Precision Mfg, we’ve found that blending both milling methods often delivers the best results. A hybrid approach uses conventional milling during initial roughing passes for stability and climb milling for finishing to get that smooth surface and prolonged tool life. For example, in a recent project machining aerospace-grade aluminum:

- We started with conventional milling to manage heavy cuts and reduce tool overload

- Switched to climb milling on finishing passes for superior surface finish and quicker throughput

- Used CNC software simulations to optimize feed and speeds for each pass, reducing cycle time by 15%

This blend helps avoid common pitfalls like excessive tool wear and poor chip evacuation, proving that knowing when and how to switch between climb and conventional milling is key to maximizing efficiency and quality.

Impact on Tool Life Surface Finish and Efficiency

Tool Wear and Longevity Differences Between Climb and Conventional Milling

Climb milling generally puts less stress on the cutting tool because the chip thickness starts thick and gradually thins, reducing tool deflection and heat buildup. This leads to longer tool life and less frequent replacements. Conventional milling, on the other hand, tends to push the tool into the material with a thinner chip first, causing more rubbing and faster wear.

- Climb Milling: Reduced tool wear, better heat dissipation, longer tool life

- Conventional Milling: Increased tool wear, more rubbing, shorter tool life

Surface Quality Metrics and Coolant Use

When it comes to surface finish, climb milling usually wins because the cutting action pulls the material away cleanly, minimizing burrs and leaving a smoother finish. Conventional milling can leave a rougher surface due to the initial rubbing before the cut starts. Coolant usage plays a role in both but is particularly important in conventional milling to reduce heat and tool wear.

- Surface Finish: Climb milling offers smoother, cleaner cuts

- Coolant Use: Essential in both, but more critical with conventional milling to prevent overheating

Overall Efficiency Gains and Optimization Tips

Climb milling often allows for higher feed rates and faster RPMs because of better chip evacuation and less tool wear, boosting overall productivity. Conventional milling may require slower speeds but can still be useful where machine rigidity or backlash issues exist.

| Factor | Climb Milling | Conventional Milling |

|---|---|---|

| Recommended RPM | Higher | Lower |

| Feed Rates | Faster | Slower |

| Chip Evacuation | Efficient | Less efficient |

| Tool Life | Longer | Shorter |

| Surface Finish | Better | Rougher |

Optimization Tips:

- Use climb milling whenever possible on CNC machines with proper backlash compensation.

- Adjust feed and speed charts according to material and cutter specs.

- Apply coolant strategically to manage heat and extend tool life.

- Run precut tests to find the sweet spot for your machine and tooling setup.

Common Mistakes and Troubleshooting Avoid Pitfalls in Your Shop

Frequent Errors Using Climb and Conventional Milling

- Choosing the wrong milling direction for the material or setup. For example, using climb milling on machines with backlash can cause tool deflection and poor surface finish.

- Ignoring machine condition and stiffness. Conventional milling can better handle older or less rigid machines, but applying climb milling in such cases often leads to chatter and vibration.

- Poor chip evacuation during climb milling. Since chips flow differently in climb milling, failing to optimize coolant and chip clearance can cause tool damage.

- Incorrect feeds and speeds. Using climb milling speeds and feeds when the cutter isn’t suited for it results in tool wear or breakage.

- Overlooking backlash compensation in CNC. Without proper compensation, climb milling results in dimensional inaccuracies.

Diagnostics and Signs of Wrong Milling Choice

- Excessive tool wear or rapid dulling indicates a mismatch between milling method and cutter/tool setup.

- Unusual vibrations or chatter marks often show that the milling direction or parameters aren’t optimized.

- Poor or inconsistent surface finish, especially rough or smeared finishes, can signal the wrong milling type.

- Difficulty in controlling chip load or buildup, meaning chips stick or clog instead of evacuating properly.

- Unexpected dimensional inaccuracies, often from machine backlash affecting climb milling.

Solutions Including Precut Tests Software Simulations and Consulting XTJ

- Run precut or dry run tests on scrap material to check chip flow, surface quality, and tool response before actual production.

- Use software simulations that model chip formation and milling forces; these help predict problems without wasting material or tool life.

- Adjust feeds and speeds based on those simulations and real-world test results, tuning for material and machine specifics.

- Consult with experienced teams like XTJ Precision Mfg for tailored advice on tool selection, milling direction, and machine setup.

- Regularly maintain machines to reduce backlash and vibration — especially critical when using climb milling techniques.

By addressing these common mistakes early and using testing combined with expert insight, you’ll avoid costly downtime, improve tool life, and get better surface finishes regardless of whether you’re climb milling or conventional milling.

FAQs Quick Answers on Climb vs Conventional Milling

Here are quick answers to common questions about climb milling vs conventional milling, especially for shops in the U.S. using CNC machines.

What are the main differences between climb and conventional milling?

| Aspect | Conventional Milling (Up Milling) | Climb Milling (Down Milling) |

|---|---|---|

| Cutter rotation vs feed | Cutter rotates against feed direction | Cutter rotates with feed direction |

| Chip thickness | Starts thin, thickens throughout cut | Starts thick, thins out |

| Cutting forces | Pushes workpiece upward | Pulls workpiece downward |

| Tool deflection | Higher, more tool wear | Lower, better tool life |

| Surface finish | Rougher finish | Smoother finish |

| Recommended use | Older machines with backlash | Modern CNCs with rigid setups |

Is climb milling suitable for CNC machines?

Yes, climb milling is generally better for CNC machines because it provides a smoother cut, improved tool life, and better chip evacuation. However, it requires machines with minimal backlash and solid rigidity to avoid tool damage or poor finish.

How does milling direction affect tool life?

- Climb milling usually extends tool life due to lower cutting forces and less rubbing.

- Conventional milling often causes faster tool wear since the cutter teeth rub more against the material before cutting.

Can both milling methods be mixed in a process?

Absolutely. Hybrid strategies can combine climb milling for finish cuts and conventional milling for roughing, optimizing both tool life and surface quality.

What are common mistakes to avoid with each method?

- Using climb milling on machines with backlash can cause tool crash or poor finish.

- Over-relying on conventional milling can lead to excessive tool wear and rough surface finish.

For more detailed insights on optimizing milling processes for CNC, check out this guide on how to optimize your face milling process for superior results.