Custom CNC Acrylic Services

For designers and manufacturers, XTJ Precision Mfg delivers unparalleled custom CNC acrylic services. With over 20 years of expertise, we provide precision, flexibility, and efficiency to create standout projects tailored to your needs.

- Precision machining for intricate designs

- Flexible solutions for diverse industries

- Lead Times from 5 Days for Rapid Delivery

- Tailored services to meet unique requirements

Understanding CNC Acrylic Services

CNC, or Computer Numerical Control, refers to the automation of machine tools through the use of computers. In the context of acrylic services, CNC machines are used to cut and shape acrylic materials with incredible precision. This technology allows for the creation of intricate designs and patterns that would be impossible to achieve by hand. The integration of computer technology into machining processes has opened up new possibilities for precision engineering, transforming the way custom projects are developed and executed.

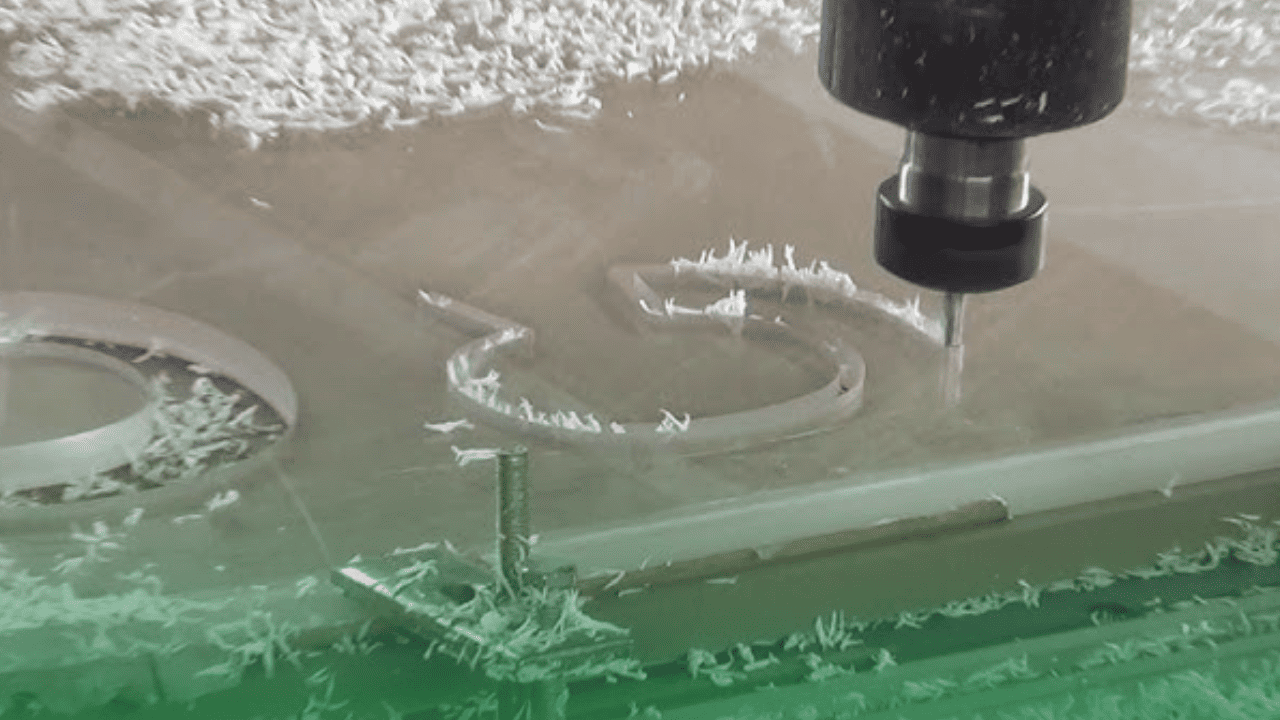

The Precision of CNC Acrylic Cutting

One of the main advantages of using CNC machines for acrylic cutting is precision. The machines are programmed with exact specifications, ensuring that each cut is perfect. This level of precision is particularly important for projects that require intricate designs or tight tolerances. Whether you’re creating a small component for a model or a large installation piece, CNC acrylic cutting ensures that every piece fits together perfectly. The ability to achieve such precision consistently enhances the reliability and quality of the final product, which is crucial in industries where accuracy is paramount.

Moreover, precision in CNC cutting doesn’t just apply to the size and shape of the pieces but also to the quality of edges and surfaces. The smoothness and clarity of the cut edges achieved by CNC machines are difficult to replicate with traditional methods, providing a superior finish that enhances the aesthetic appeal and functionality of the final product. This precision minimizes errors and rework, saving time and resources in the production process.

Flexibility and Creativity

CNC acrylic services are incredibly versatile. They can be used to create a wide range of products, from simple signs and displays to complex sculptures and architectural elements. The flexibility of CNC machines means that you can create virtually any design you can imagine. This opens up a world of possibilities for artists and designers, allowing them to push the boundaries of what is possible. With CNC technology, creative professionals can experiment with new ideas and bring innovative designs to fruition without being constrained by traditional manufacturing limitations.

The flexibility of CNC acrylic services also facilitates rapid prototyping, allowing designers to quickly produce and test different iterations of a product. This ability to rapidly iterate and refine designs promotes creative exploration and innovation. Additionally, CNC machines can handle various thicknesses and types of acrylic, making it easier to select the best material for each unique project. This adaptability ensures that projects are not only creative but also functional and durable.

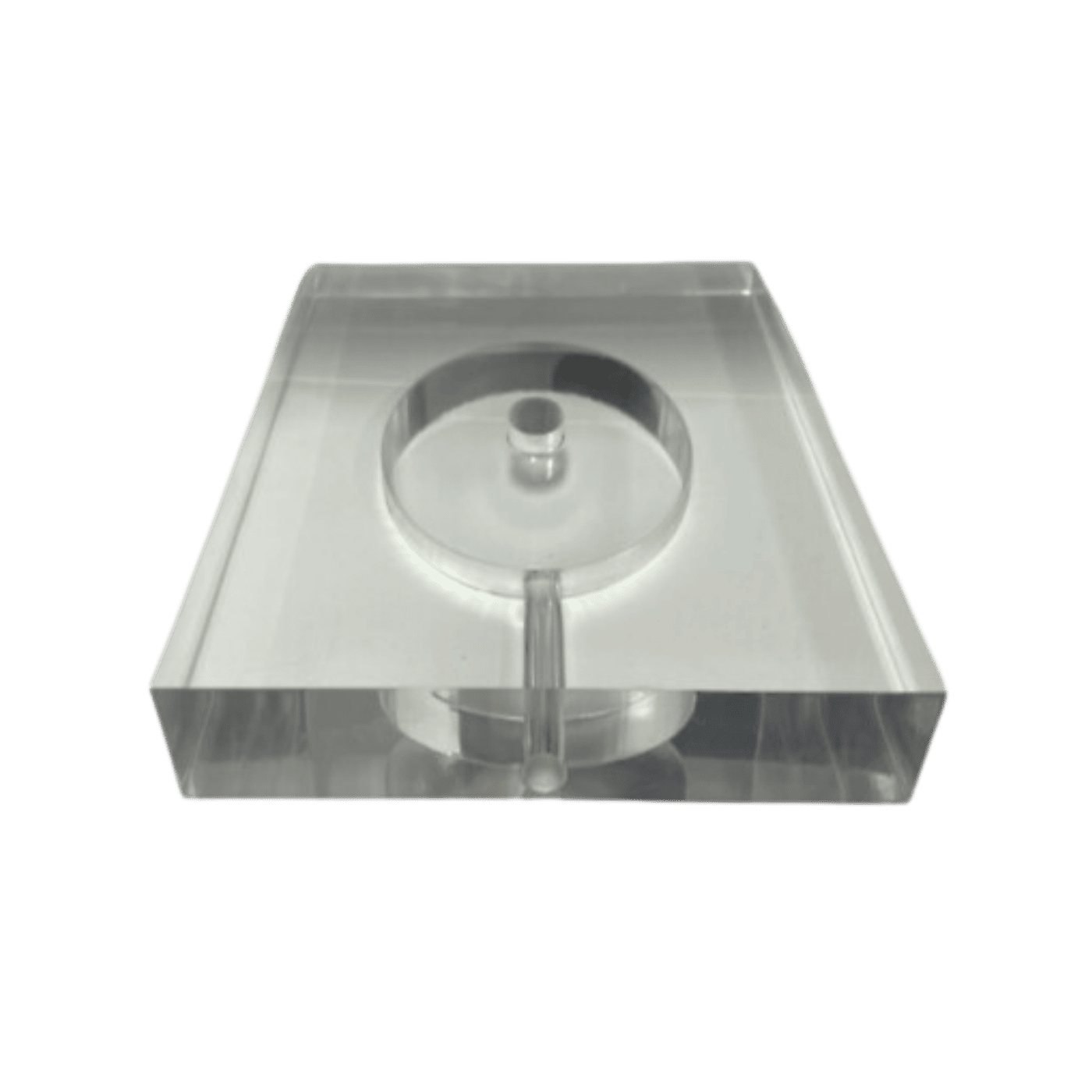

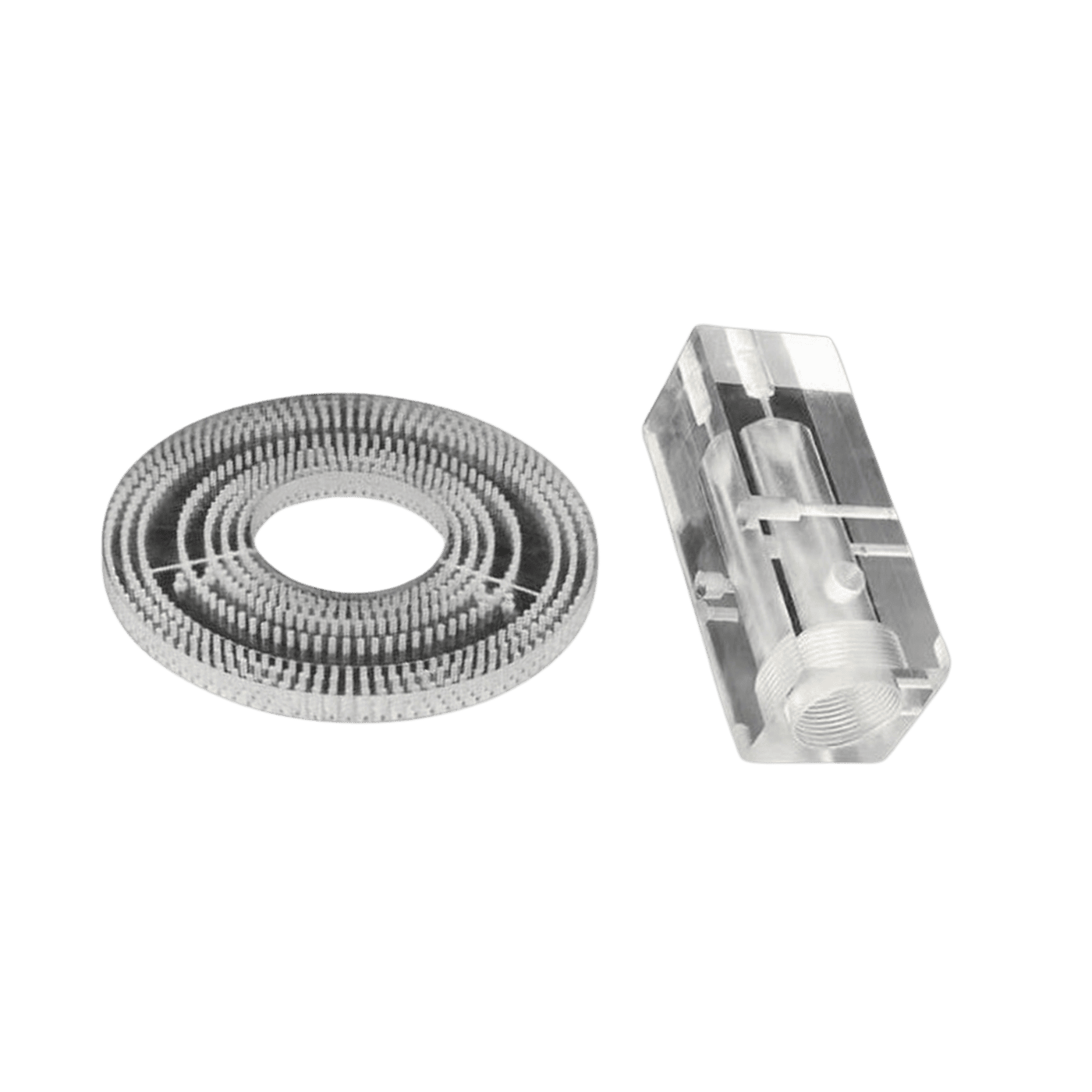

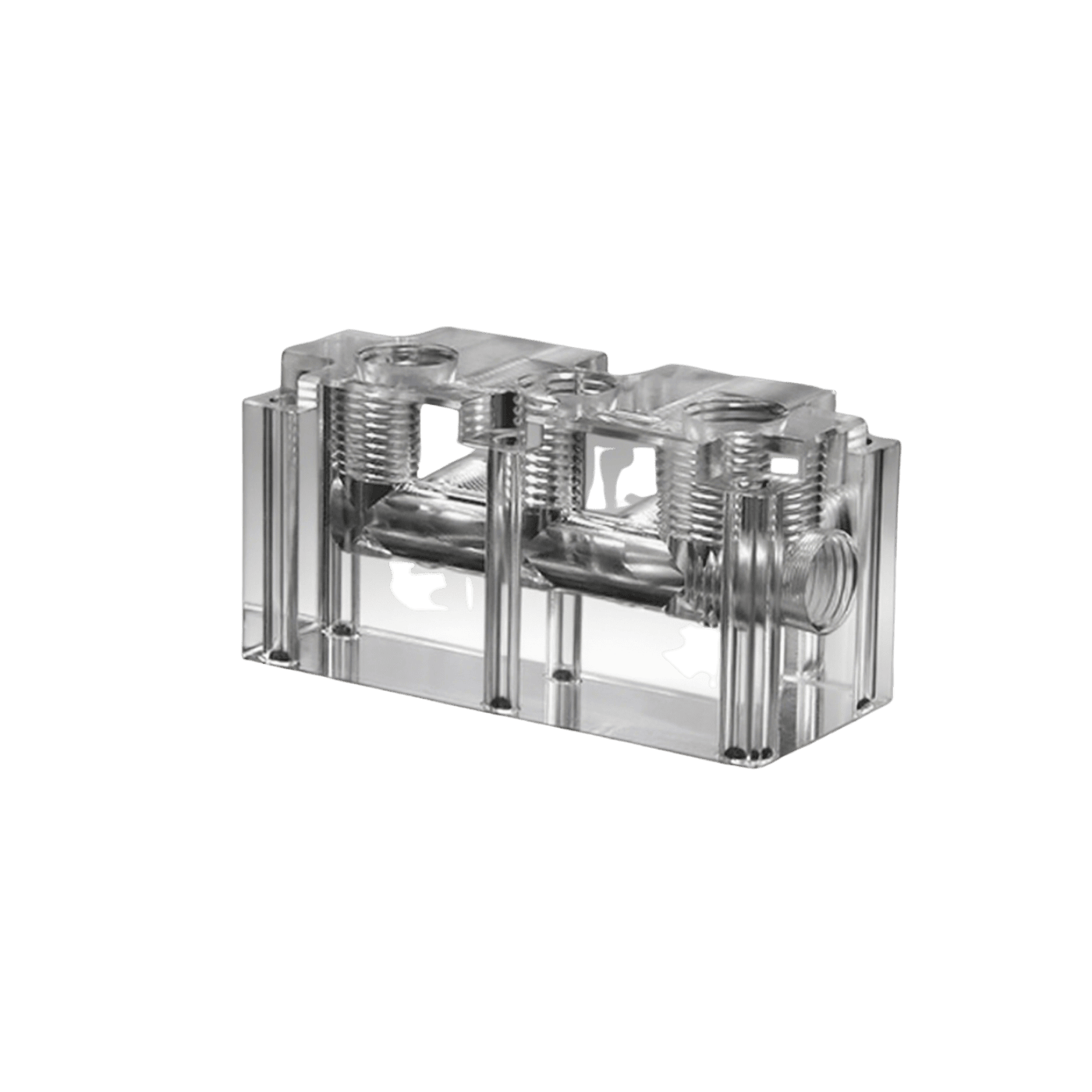

Advanced CNC Machining Services for Your Acrylic Parts

Are you searching for a trusted partner to deliver precision CNC machining for your acrylic components?

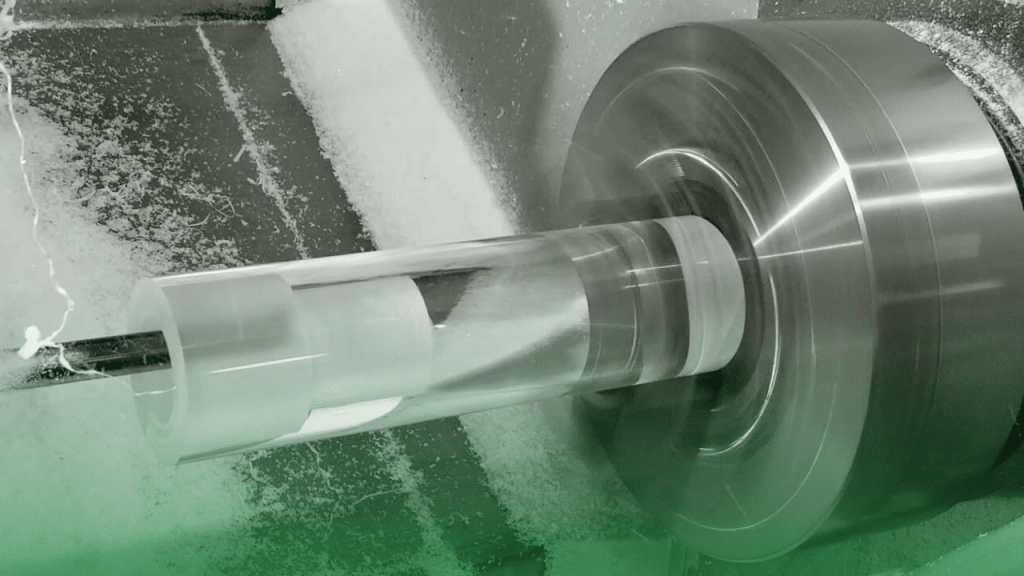

XTJ Precision Mfg is a leading provider of CNC machining services based in China, specializing in high-quality acrylic parts. Our comprehensive capabilities, including 3-axis, 4-axis, and 5-axis CNC milling, turning centers, and CNC lathe machines, enable us to produce precise, top-quality acrylic components tailored to your exact specifications. With over 100 advanced CNC machines and more than 20 years of industry experience, XTJ Precision Mfg is your ideal partner for outsourcing custom and precision CNC acrylic machining, no matter your industry.

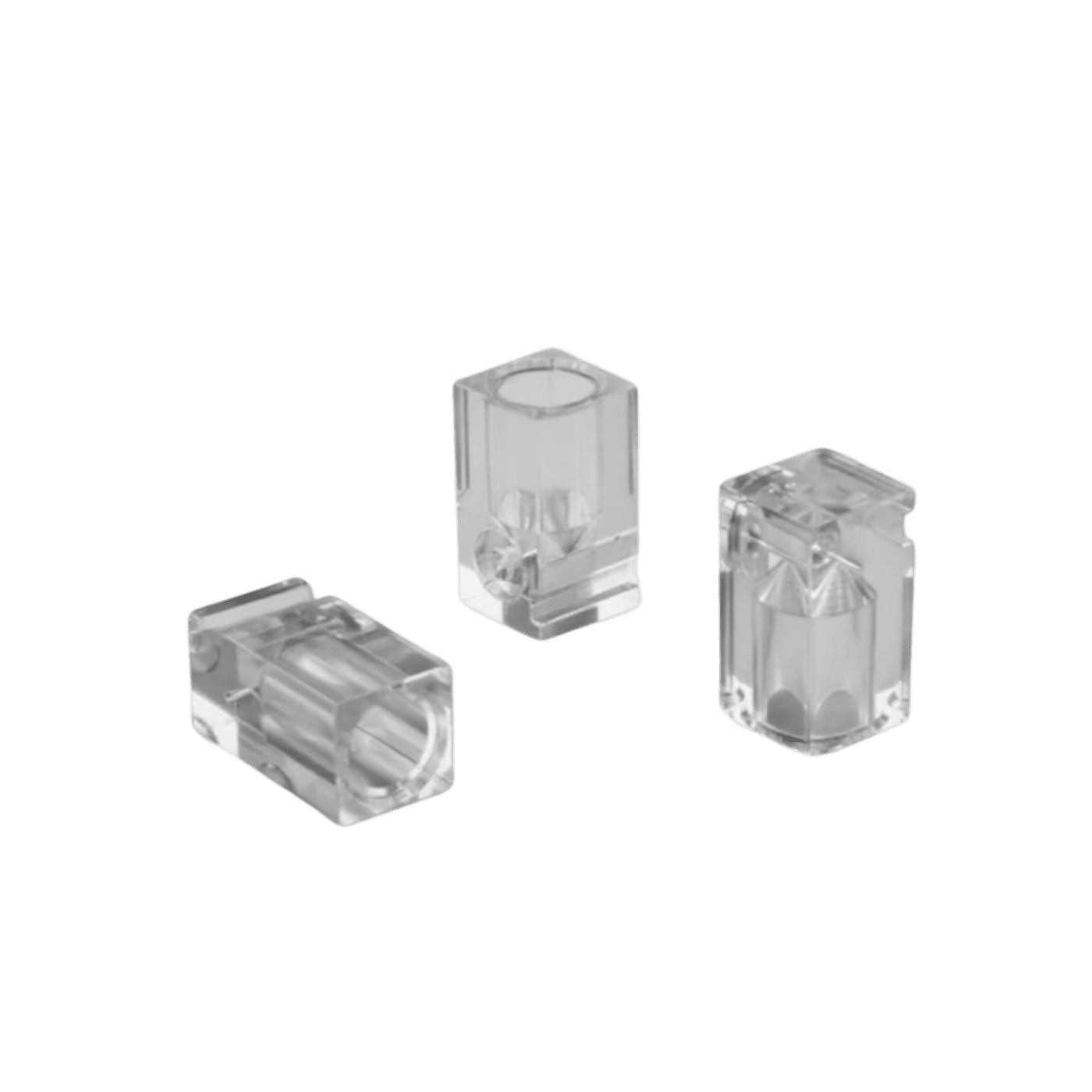

Optimized CNC milling machining service for Acrylic Parts, offeringprecision and versatility with 3,4.and 5-axis capability.

Efficient cnc turning with live tooling for machining Acrylic parts with cylindrical features, combining lathe and milling capabilities.

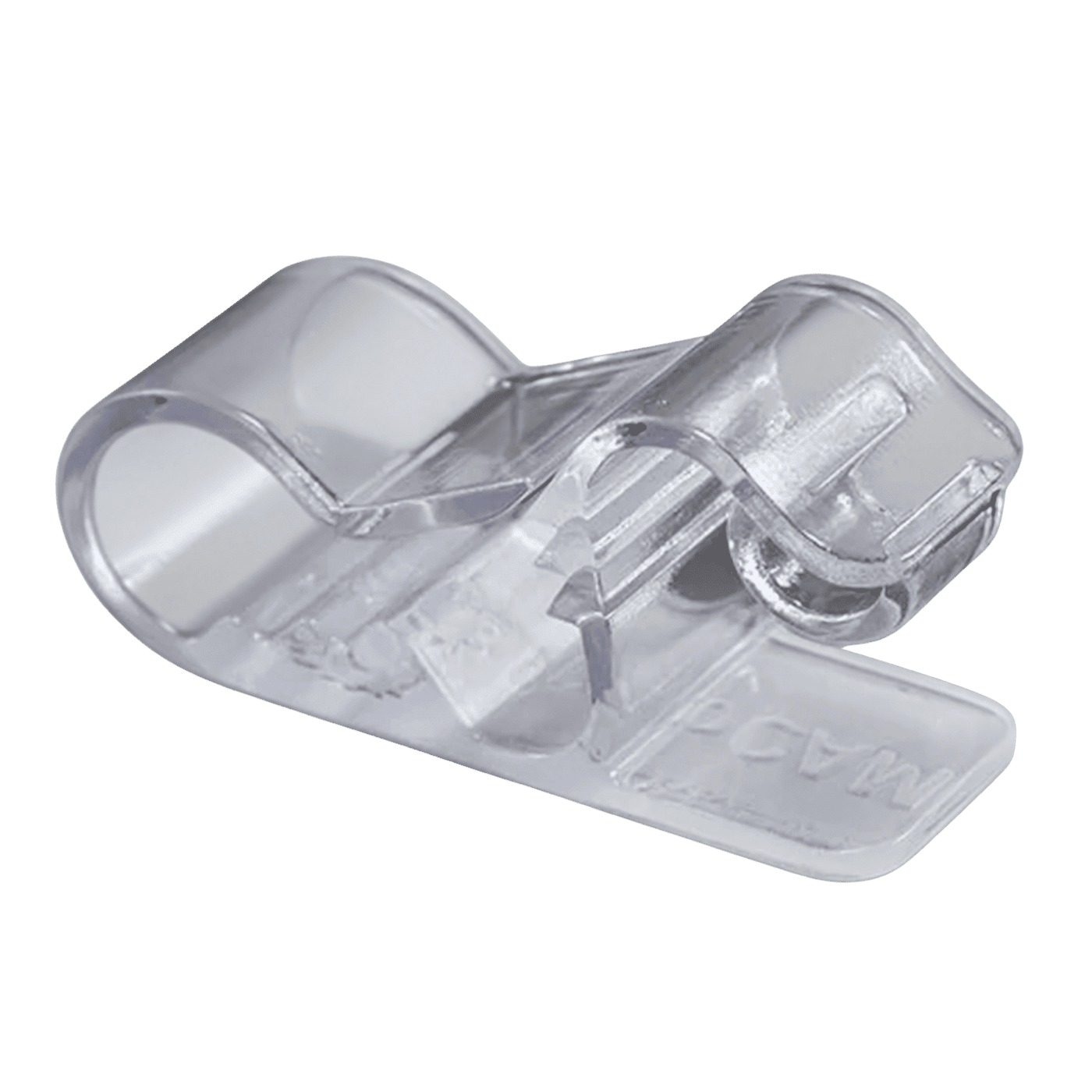

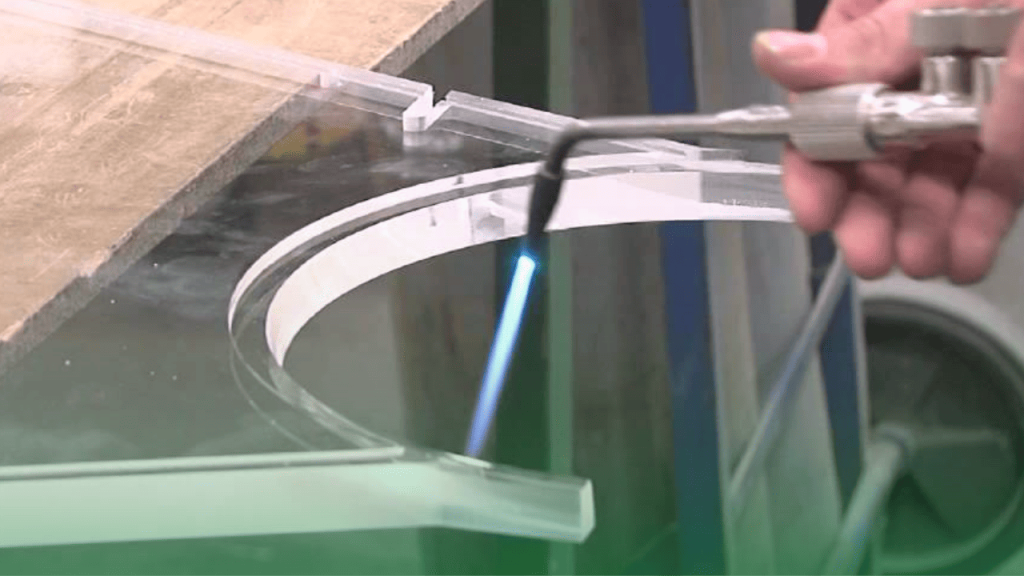

The surface finish of the CNC machined Acrylic parts can be further improved with additional finishing techniques such as polishing or sandblasting.

Benefits of Acrylic CNC Services

CNC acrylic services offer numerous benefits for custom projects. These benefits make them an attractive option for anyone looking to create high-quality, custom pieces. Whether for individual creators or large-scale manufacturers, CNC acrylic services provide solutions that enhance production capabilities and output quality.

Cost-Effective Production

Despite the precision and flexibility they offer, CNC acrylic services are surprisingly cost-effective. The automation of the process reduces labor costs, and the precision of the machines minimizes waste. This means that you can produce high-quality custom pieces without breaking the bank. By optimizing material usage and reducing manual intervention, CNC services help keep production expenses in check, making high-quality customization accessible to a wider range of clients and projects.

The cost-effectiveness of CNC acrylic services also lies in their ability to produce consistent results at scale. For businesses looking to manufacture large quantities of a product, CNC machines can replicate designs with pinpoint accuracy, ensuring uniformity and reducing the likelihood of defective products. This consistency contributes to cost savings by minimizing material loss and the need for extensive quality control measures.

Speed and Efficiency

CNC machines are incredibly fast and efficient. Once a design is programmed into the machine, it can be reproduced quickly and consistently. This is especially beneficial for projects that require multiple identical pieces or for businesses that need to produce large quantities of a product. The speed and efficiency of CNC acrylic services can significantly reduce production times. This efficiency enables businesses to meet tight deadlines and respond quickly to market demands, enhancing their competitive edge.

In addition to reducing production times, the automation of CNC processes allows for continuous operation with minimal supervision. This capability is particularly advantageous for businesses that operate on a 24/7 schedule, enabling them to maximize output and profitability. The reliable and efficient nature of CNC acrylic services ensures that projects are completed on time and to the highest standards.

High-Quality Finish

Acrylic is a material that can be tricky to work with. It requires careful handling to avoid cracking or chipping. CNC machines handle acrylic with the precision and care it requires, resulting in a high-quality finish. The edges are smooth and clean, and the surface is free from blemishes. This quality finish adds a professional touch to any project. The superior finish achieved with CNC cutting enhances the visual appeal and functionality of the final product, making it suitable for both artistic and commercial applications.

The high-quality finish provided by CNC acrylic services also contributes to the durability and longevity of the products. By minimizing the risk of defects and imperfections, CNC machines ensure that the final product meets or exceeds industry standards for quality and performance. This reliability is essential for applications where appearance and durability are critical, such as in retail displays, signage, and architectural elements.

Applications of CNC Acrylic Services

The applications of CNC acrylic services are vast and varied. Here are just a few examples of how they can be used in different industries. As technology continues to evolve, the potential uses for CNC acrylic services expand, offering innovative solutions across a range of fields.

Signage and Displays

Acrylic is a popular material for signage and displays due to its clarity and durability. CNC acrylic services can create custom signs and displays that are eye-catching and professional. Whether you need a simple nameplate or an elaborate storefront display, CNC machines can produce the perfect piece. The precision and customization options offered by CNC services allow businesses to create signage that not only conveys information but also enhances their brand identity.

Art and Design

Artists and designers can use CNC acrylic services to bring their visions to life. The precision and flexibility of the machines allow for the creation of intricate sculptures, installations, and other art pieces. CNC acrylic services enable artists to explore new techniques and push the boundaries of their creativity. By incorporating advanced technology into their creative process, artists can achieve levels of detail and complexity that were previously unattainable.

Industrial and Commercial Use

In the industrial and commercial sectors, CNC acrylic services are used to create a variety of components and products. From machine parts to protective covers, acrylic is used for its strength and versatility. CNC machines can produce these components quickly and accurately, ensuring that they meet the necessary specifications. The reliability and efficiency of CNC acrylic services make them a valuable asset in manufacturing and production environments.

CNC acrylic services also play a crucial role in product development and prototyping, allowing engineers and designers to test and refine their designs before full-scale production. This capability reduces the risk of errors and ensures that the final product meets the required standards for quality and performance. The adaptability of CNC technology to various industrial applications supports innovation and continuous improvement in manufacturing processes.

CNC Acrylic Services FAQs

We specialize in machining acrylic components such as custom enclosures, signage, lighting fixtures, and medical device parts using our 3-axis, 4-axis, and 5-axis CNC equipment, ensuring precision for both prototypes and production runs.

Our process includes using premium acrylic materials, advanced CNC machines, and rigorous quality control. We also apply specialized polishing techniques to achieve smooth, optically clear finishes tailored to your specifications.

We maintain tolerances as tight as ±0.005 inches (0.13 mm) depending on part complexity and design, leveraging our 20+ years of experience and over 50 CNC machines to meet industry standards.

Turnaround time varies by project scope—prototypes can be completed in 3-5 days, while production runs may take 1-4 weeks. Contact us with your details for an accurate timeline and quote.

Consider acrylic’s excellent light transmission (up to 92%), impact resistance, and ease of machining. For high-heat or chemical exposure applications, consult our team to evaluate alternatives like glass or polycarbonate.

Get a Free Quote Today

Get started by contacting us for a free quote and let us bring your acrylic projects to life with unmatched precision and efficiency.