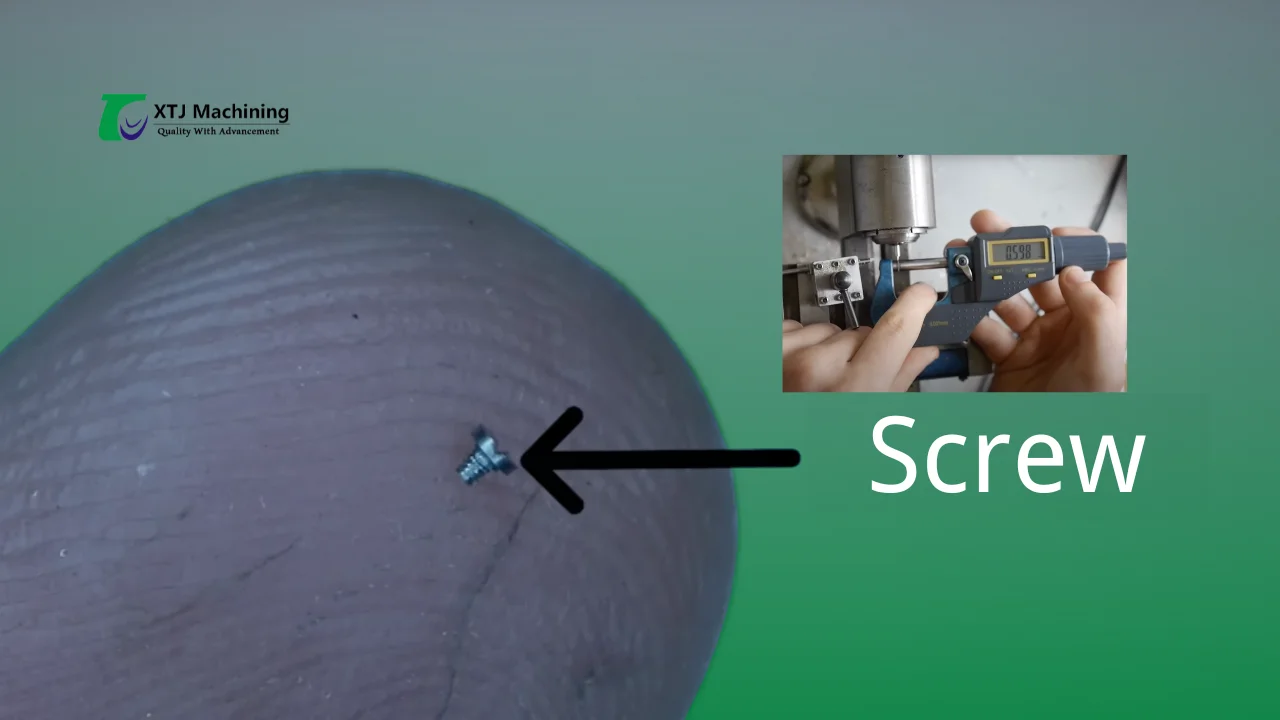

At XTJ , we specialize in high-precision micro-component machining. In this case study, we highlight a challenging project for a luxury watch manufacturer: CNC machining a 0.6mm diameter watch screw using a watchmaker’s lathe. This collaboration demonstrates our expertise in micro-precision engineering, enabling clients to achieve intricate design specifications with exceptional accuracy.

Project Brief

|

Industry: |

Watchmaking / Precision Engineering |

|

Materials: |

Silver steel rod (starting diameter: 3mm) |

|

Surface Finish: |

As machined, with optional post-processing (cleaning, hardening, bluing) |

|

Technology: |

CNC watchmaker’s lathe (2000-6000 RPM) |

|

Lead Time: |

Efficient turnaround to meet tight production schedules |

|

Final Result: |

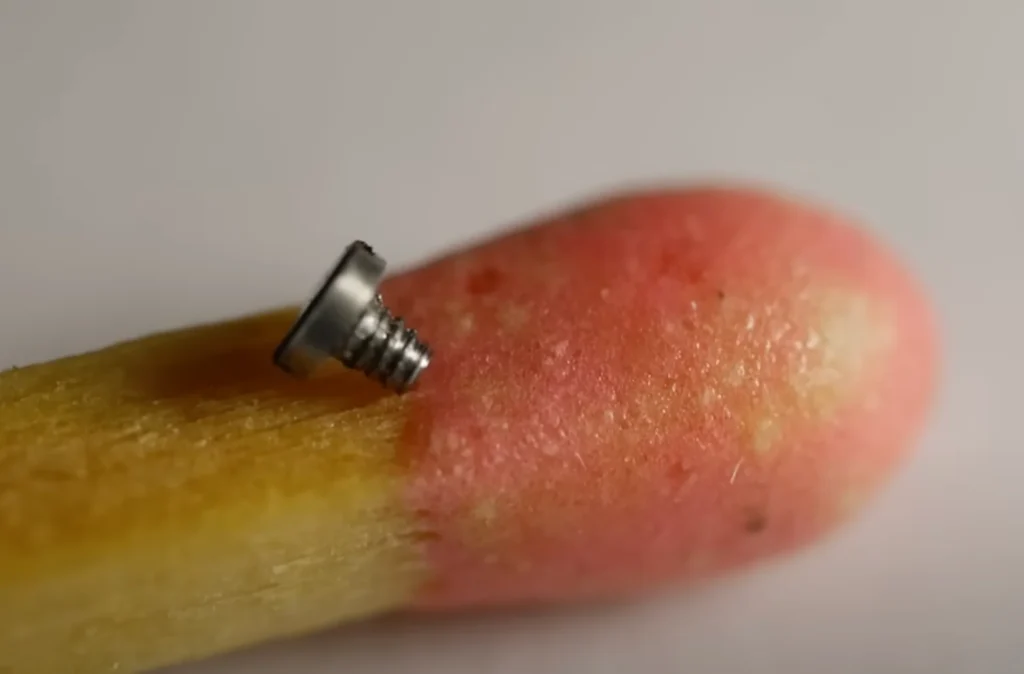

High-precision screws with 0.6mm diameter shaft, 1mm head, threaded and slotted, delivered to exact specifications |

Project Background

The client, a leading mechanical watch producer, required ultra-precise screws for assembling high-end timepieces. These components needed a 0.6mm diameter shaft, approximately 1mm head diameter, complete with threading and a slot for installation. Starting from a 3mm silver steel rod—chosen for its high strength and wear resistance—we selected a watchmaker’s lathe as the primary tool. Its high-speed capabilities (2000-6000 RPM) make it ideal for handling delicate micro-parts without compromising quality.

Our goal was to deliver components that not only met but exceeded the client’s tolerances, ensuring seamless integration into their luxury watches.

Challenges Encountered

Micro-machining at this scale presented several hurdles, as highlighted in expert demonstrations:

- Thread Deformation and Shear Risks: The tiny dimensions made the parts susceptible to warping during threading and potential breakage from excessive force, especially when the die first engages the material.

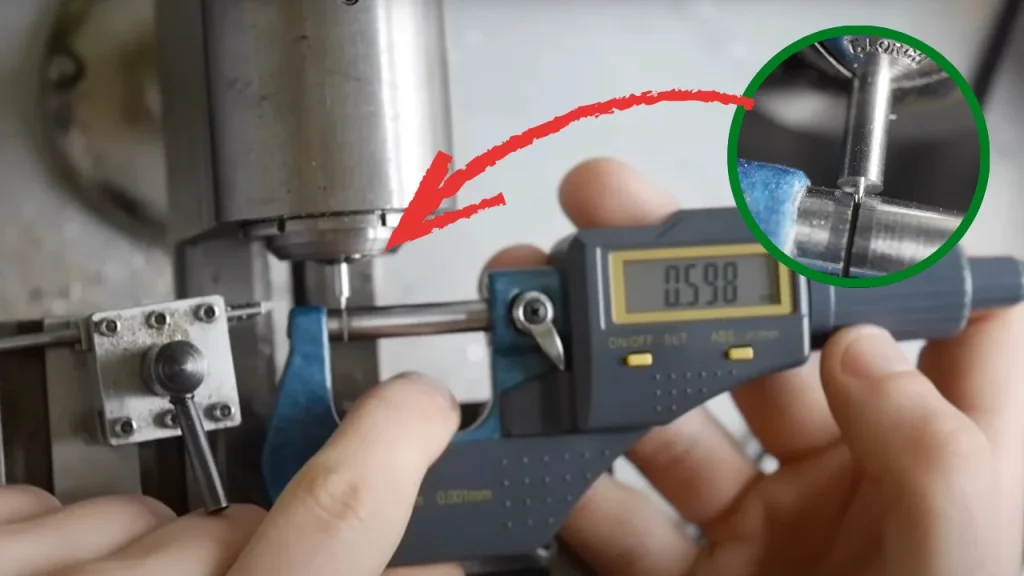

- Precision Control: Maintaining tolerances on a 0.6mm diameter required meticulous monitoring to avoid deviations, with even slight vibrations causing irregularities.

- Material Handling: Working with small components increased the risk of loss or damage during processing, necessitating tools like magnets for recovery.

- Efficiency in Small-Batch Production: Balancing speed with accuracy while keeping costs competitive for prototyping or low-volume runs, all while managing heat buildup at high speeds.

XTJ’s Innovative Solutions and Manufacturing Process

To overcome these challenges, our team employed a step-by-step approach with custom optimizations, leveraging our advanced CNC capabilities and experienced engineers. Inspired by professional scripting details, we incorporated techniques like intentional over-threading to compensate for initial deformities. The process was divided into key stages for maximum control:

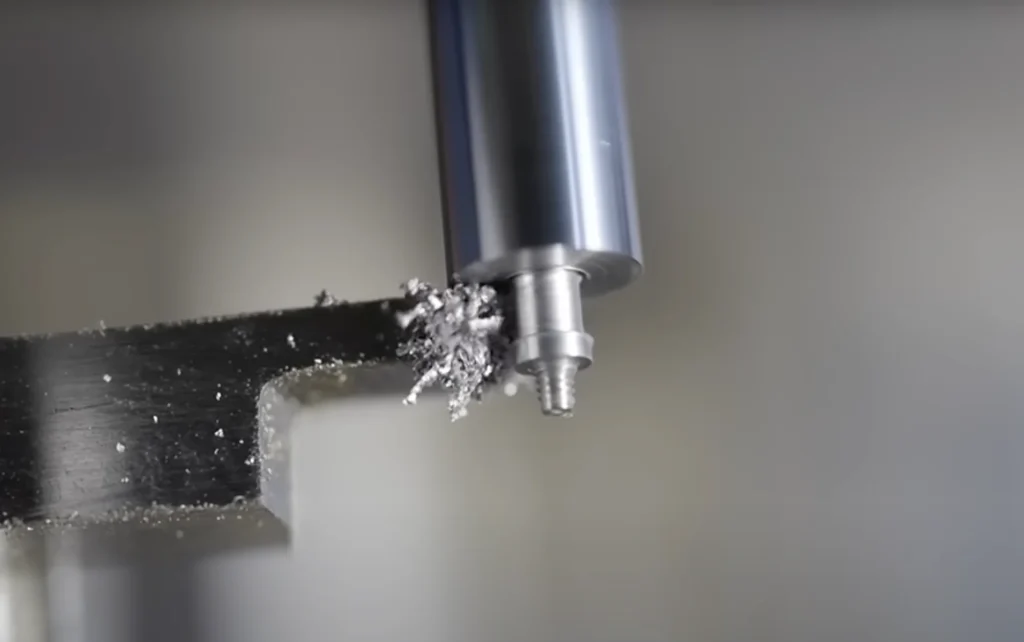

- Preparation and Rough Turning: Beginning with the 3mm silver steel rod, we turned it down to slightly under 0.6mm diameter. A chamfer was added to the screw end to facilitate threading, as this “helps the die start more easily.” The lathe’s high-speed spindle (set to around 4000 RPM for this step) ensured a smooth surface finish from the start, reducing the need for extensive polishing later.

- Head Forming: The screw head was faced to a precise 1mm diameter. Real-time inspection using a watchmaker’s magnifying glass allowed us to detect and correct any micro-deviations immediately. Narration tips suggest “checking under magnification at every stage to catch issues early.”

- Threading: We used a 0.6mm die for tapping. To ensure axial stability, the die was secured in the lathe’s tailstock chuck with a custom-machined brass shim for a snug fit—described as “a simple but effective way to prevent wobble.” Rocol cutting lubricant was applied beforehand to reduce friction and heat, with the advice to “apply liberally to avoid galling on such fine threads.” The thread was intentionally over-lengthened to account for initial deformation where “the first few threads might squish a bit,” then trimmed to exact specifications.

- Parting and Finishing: The screw was parted using a 0.6mm collet, then reversed for final head facing. The head slot was manually cut with a piercing saw fixed in a pin vise or tailstock chuck, avoiding slotting saws to minimize damage risks. Expert commentary notes that “hand-filing the slot ensures control and prevents over-cutting on delicate parts.”

- Quality Control: Magnets were used throughout to recover any dropped micro-parts, a practical tip for “saving those tiny screws that love to disappear.” Final inspection under magnification confirmed dimensions and integrity. Optional post-treatments like cleaning, hardening, and bluing were available per client needs, with bluing providing “that classic watch screw finish for corrosion resistance.”

These solutions, including the custom brass shim, optimized lubrication, and high-RPM settings, mitigated deformation risks while our engineers’ expertise prevented common pitfalls, such as over-application of force or inadequate lubrication leading to thread stripping.

Outstanding Results

The delivered screws achieved superior precision and dimensional consistency, perfectly aligning with the client’s requirements. This project enhanced the watch assembly quality, reducing defects and improving overall performance in their luxury timepieces. By partnering with XTJ, the client benefited from faster prototyping, cost-effective micro-machining, and reliable scalability for future productions.

This case study exemplifies XTJ commitment to pushing the boundaries of micro-precision machining. Whether you’re in watchmaking, aerospace, or medical devices, our end-to-end services—from design consultation to production—ensure your projects succeed. Ready to bring your ideas to life? Visit cncpartsxtj.com for a free quote and discover how we can support your next precision engineering challenge.