CNC Machining of Bronze Alloys for Custom Parts and Prototypes

CNC Bronze Machining Services

- Precision machining for intricate designs

- Flexible solutions for diverse industries

- Lead Times from 5 Days for Rapid Delivery

- Tailored services to meet unique requirements

CNC Machining Bronze for Custom Parts and Prototypes

At XTJ Precision Mfg, we specialize in high-precision CNC bronze machining, delivering custom parts that combine durability, corrosion resistance, and superior performance. Whether you’re prototyping innovative designs or scaling up production for demanding industries, our state-of-the-art CNC capabilities ensure tight tolerances and flawless finishes. With years of expertise in bronze alloys, we help engineers turn complex concepts into reliable components—fast and cost-effectively.

Why Choose Bronze for CNC Machining?

Bronze, a versatile copper-based alloy, has been a cornerstone material for precision engineering for centuries. Its unique blend of strength, ductility, and low friction makes it ideal for applications where reliability under stress is paramount. Unlike steel, bronze offers exceptional machinability, allowing for smoother cuts and reduced tool wear, which translates to faster production times and lower costs.

Corrosion Resistance

Forms a protective oxide layer, excelling in marine, chemical, and humid environments.

Wear and Low Friction

Perfect for sliding or rotating parts, minimizing maintenance and extending service life.

Thermal Conductivity

Efficiently dissipates heat, supporting high-performance in extreme temperatures.

Aesthetic Appeal

Warm, golden finish enhances decorative and architectural uses.

Ductility and Strength

Balances toughness with formability for intricate designs without cracking.

Our CNC processes leverage these properties to produce parts with superior surface quality and dimensional accuracy, outperforming traditional methods like casting by reducing defects and waste.

Bronze Material Properties

Bronze alloys vary by composition—typically copper alloyed with tin, aluminum, zinc, or phosphorus—tailoring properties to specific needs. Common traits include:

- Density: 7.4–8.9 g/cm³, providing a lightweight yet robust structure.

- Hardness: Rockwell B 55–100, offering wear resistance without excessive brittleness.

- Tensile Strength: 18,000–100,000 PSI, depending on grade.

- Elongation: 10–15%, ensuring ductility for forming complex shapes.

- Maximum Service Temperature: Up to 1,800°F in select alloys.

These attributes make bronze a go-to for parts requiring both mechanical integrity and environmental resilience.

Available Bronze Grades for Machining

We stock and machine a wide range of bronze alloys to match your project requirements. Here’s a selection of our most popular grades, with key specs:

| Alloy | Machinability Rating (AISI) | Tensile Strength | Hardness | Key Features | Typical Uses |

|---|---|---|---|---|---|

| C93200 (Bearing Bronze) | 70–85 | 34,800 | 65 | Excellent low-friction, lead-enhanced for easy machining | Bearings, bushings, gears |

| C95400 (Aluminum Bronze) | 60 | 75,000–102,000 | 85-100 | High strength, superior seawater corrosion resistance | Marine fittings, valves, structural components |

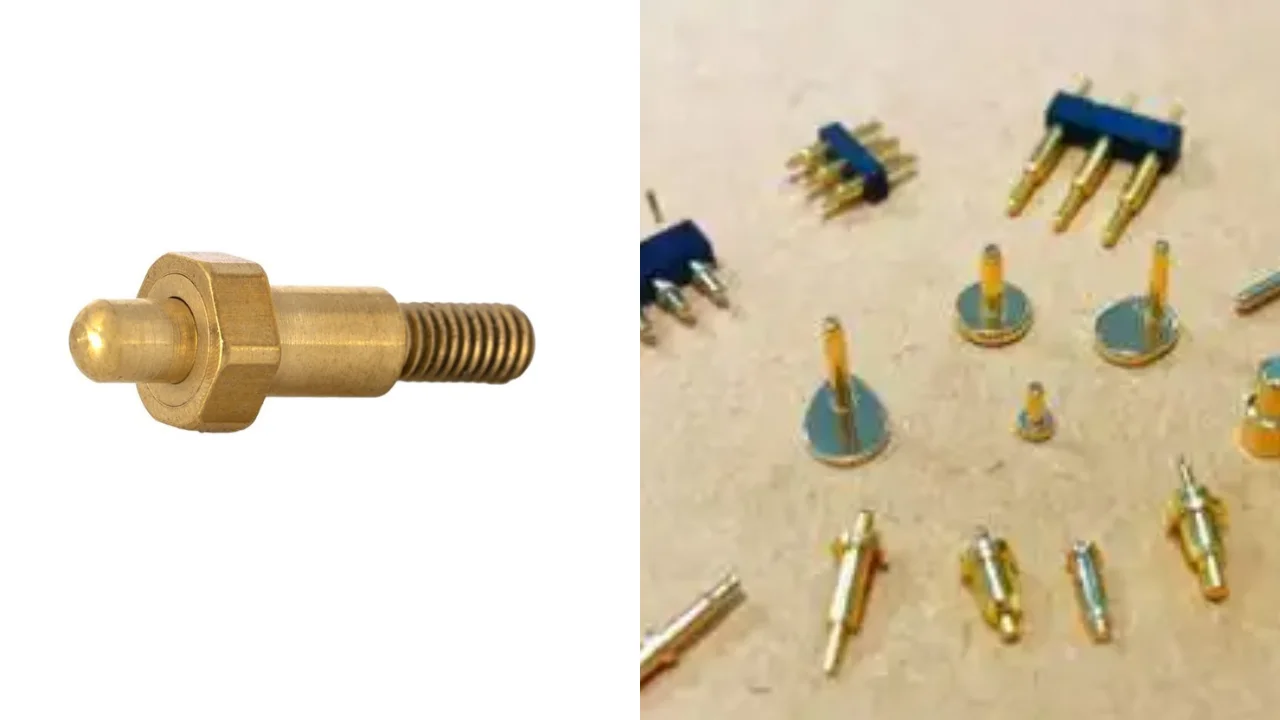

| C54400 (Phosphor Bronze) | 80 | 47,000–100,000 | N/A | High elasticity, fatigue-resistant | Electrical connectors, springs, musical instruments |

| C31400 (Leaded Bronze) | 80 | 40,000–60,000 | 56-59 | Good machinability, moderate strength | Hardware, plumbing fittings |

| C64200 (Silicon Aluminum Bronze) | 60 | 75,000–102,000 | N/A | Wear-resistant, weldable | Fasteners, architectural elements |

Note:Each grade is sourced to ASTM standards for consistent quality. Contact us for custom alloy recommendations or equivalents like C863 Manganese Bronze for heavy-duty loads.

Available Bronze Grades for Machining

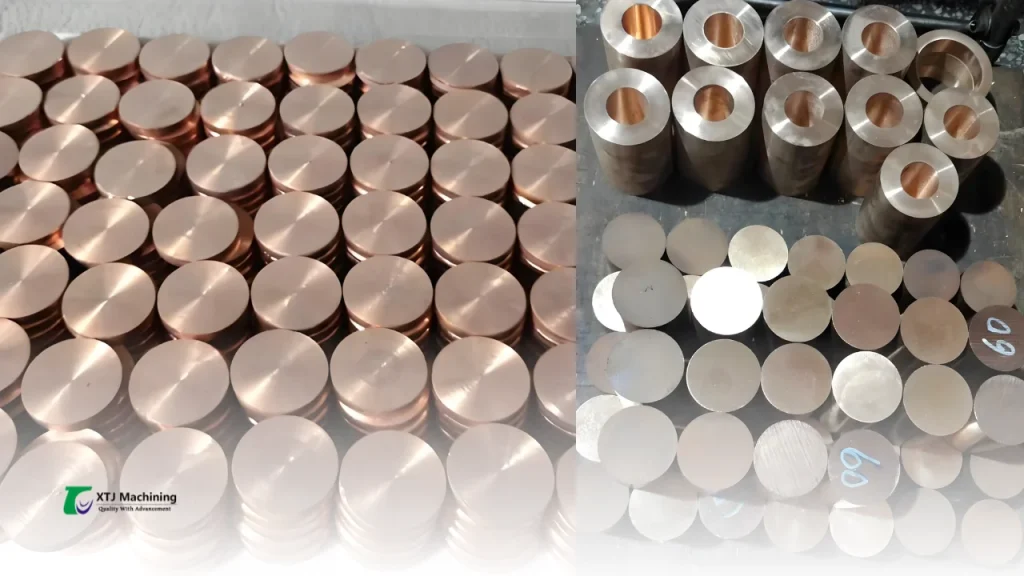

Our ISO-certified facility employs advanced 3- and 5-axis CNC mills, lathes, and multi-tasking centers to handle everything from simple turnings to intricate geometries. Bronze’s softness requires careful parameter optimization—carbide tools, controlled feeds (e.g., 0.002–0.008 in/rev), and flood coolants prevent galling and ensure clean chips.

Post-machining finishes like polishing, anodizing, plating (gold/nickel), or bead blasting enhance corrosion protection and aesthetics. Lead times start at 5–7 days for prototypes, scaling efficiently for production runs.

Tolerances and Precision Standards

Precision is our promise. Standard tolerances follow ISO 2768-m (±0.005–0.010 mm), with custom specs down to ±0.001 mm achievable via our metrology tools (CMM, optical comparators). Factors like alloy type and part size influence final accuracy—leaded grades like C932 hold tighter dims with less thermal expansion.

We design for manufacturability to avoid costly iterations, ensuring your bronze parts meet or exceed specs every time.

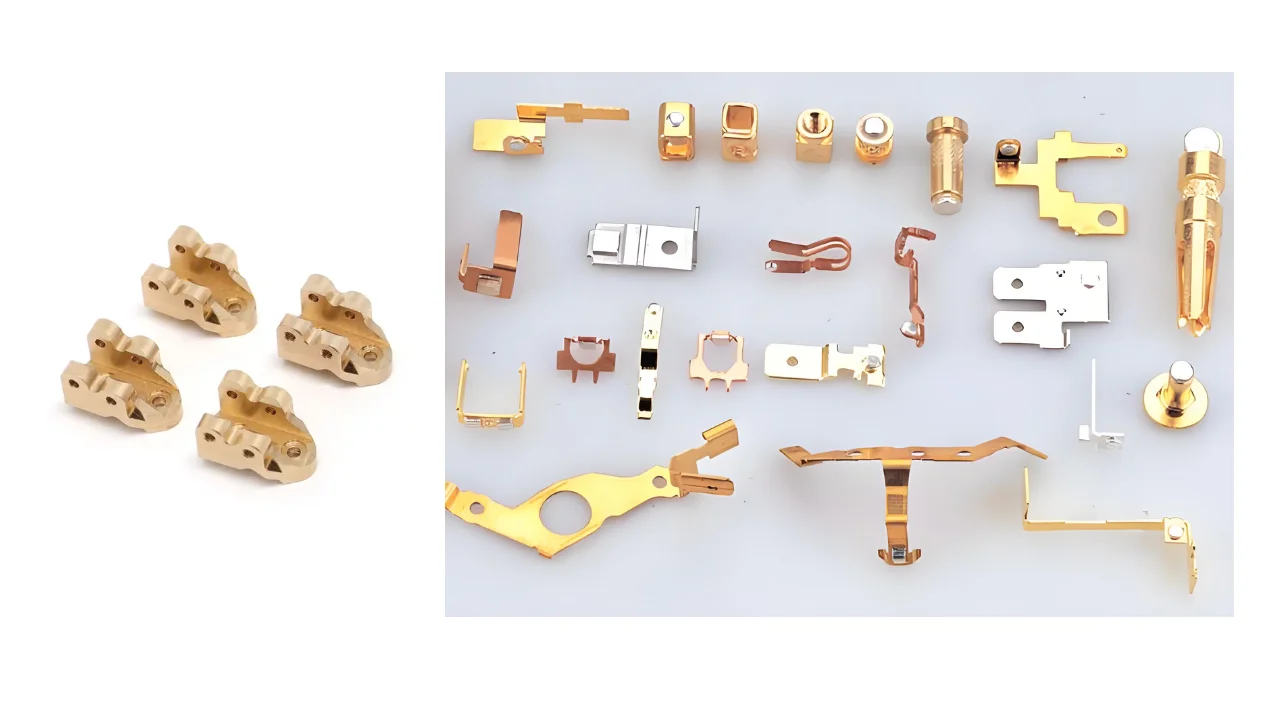

Applications of CNC Machined Bronze Parts

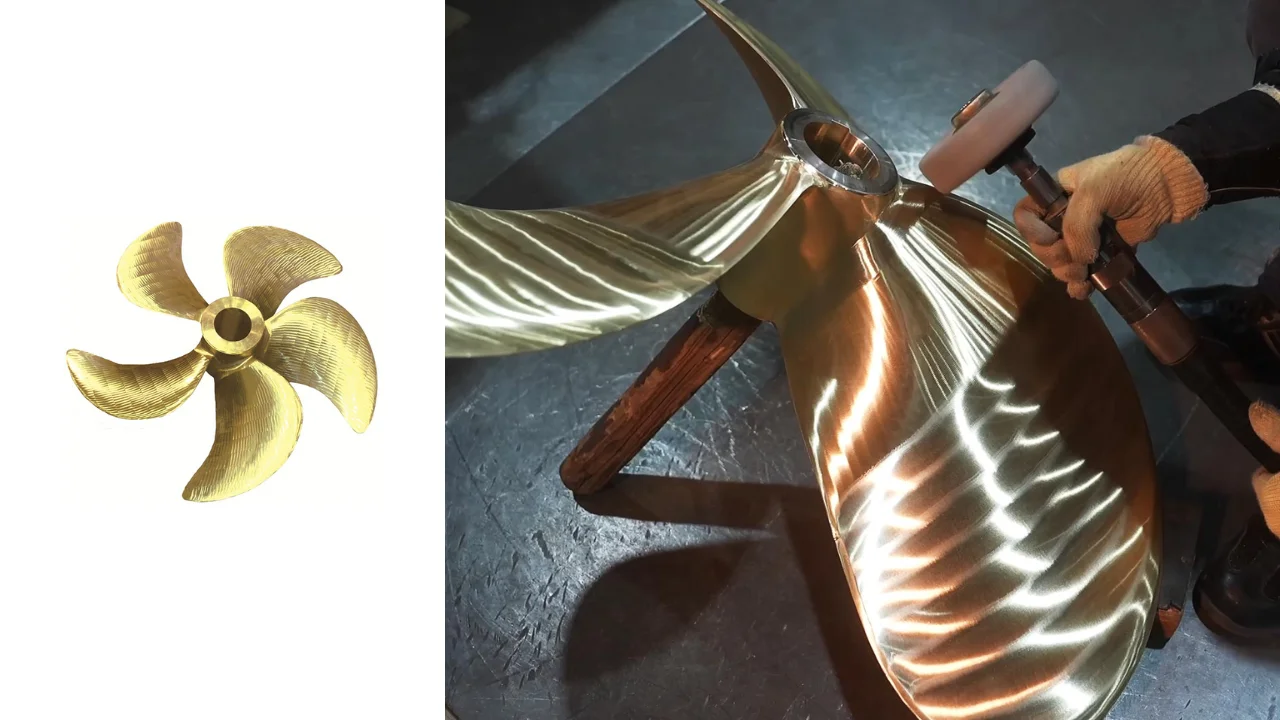

Marine & Aerospace Parts

Propellers, fittings, and manifolds resisting saltwater and fatigue.

Electronics & Electrical Parts

Connectors and springs leveraging conductivity and elasticity.

Architecture & Construction

Hardware, trims, and fixtures for durability and style.

Automotive & Medical Parts

Valves, pumps, and implants requiring biocompatibility and strength.

Industrial Machinery Parts

Bearings, gears, and bushings for low-friction operation.

Bronze Machining FAQs

Here are answers to some of the most common questions about CNC bronze machining, based on our expertise at XTJ Precision Manufacturing.

Yes, bronze is generally easy to machine due to its high machinability rating, especially alloys like C93200 bearing bronze. At XTJ, we optimize speeds and feeds for smooth cuts, reducing tool wear and achieving excellent surface finishes

C93200 (bearing bronze) is widely regarded as the best for machinability, with a rating of 85, thanks to its lead content that acts as a lubricant. We also recommend C64200 for its superior ductility and corrosion resistance in demanding applications.

Absolutely—CNC milling, turning, and drilling excel with bronze’s ductility, allowing for precise shaping and tight tolerances. Our 3- and 5-axis machines handle complex geometries with ease.

Yes, bronze is typically easier than most steels due to its lower hardness, better thermal conductivity, and manageable chip formation, leading to faster production and longer tool life. This makes it ideal for high-volume runs at XTJ.

C932 (bearing bronze) offers excellent low-friction and machinability for bearings and bushings, while C954 (aluminum bronze) provides higher strength and superior seawater corrosion resistance for structural and marine parts. We select the right grade based on your project needs.

Bronze can be more expensive than steel or aluminum, and certain high-strength alloys may increase tool wear if not optimized. However, its benefits in corrosion resistance and low friction often outweigh these for specialized uses.

Get Your Custom Bronze Parts Today

Ready to leverage the power of CNC bronze machining? Upload your CAD files for a free quote, or reach out to our engineering team for material consultations. At XTJ, we’re committed to delivering excellence—on time, on spec, and on budget.