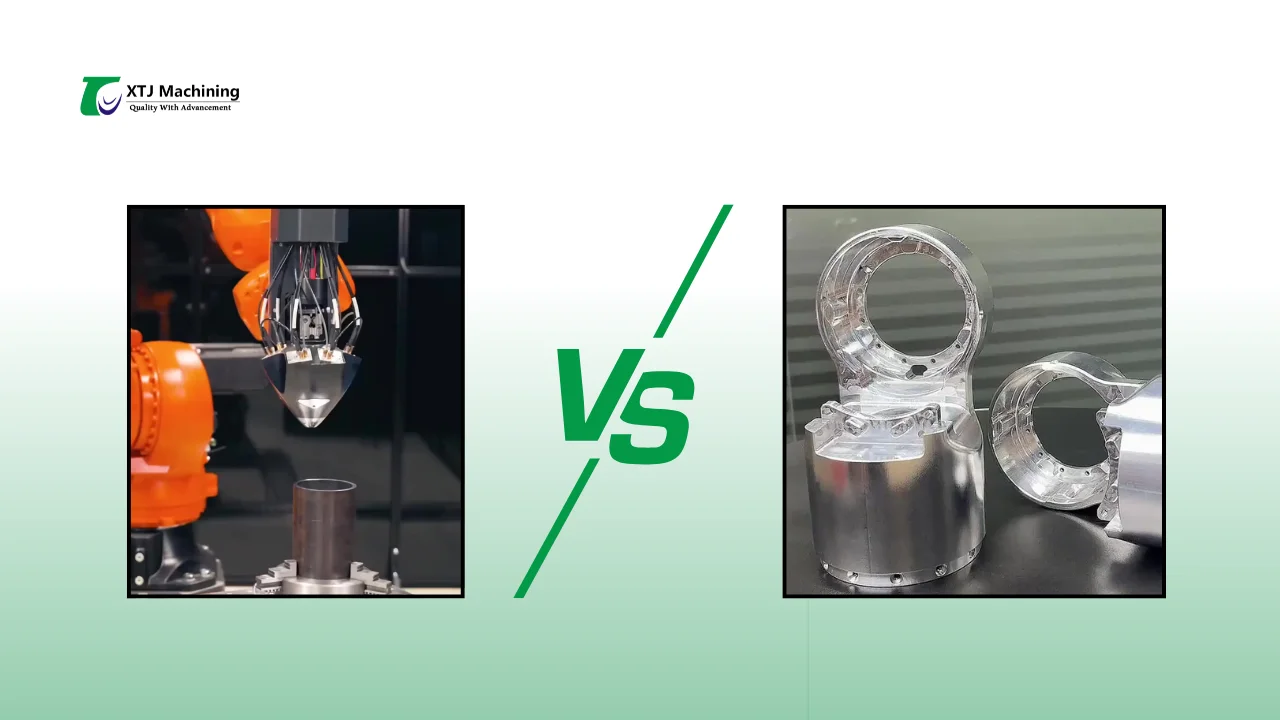

If you’re wrestling with whether CNC machining vs 3D printing for robot parts is the right choice for your project, you’re not alone. Both methods offer unique benefits—but which one truly delivers on precision, strength, and speed for your robotic build? In this post, we break down how these technologies stack up when it comes to producing critical robot components. Whether you’re prototyping a complex linkage or manufacturing a heavy-duty frame, understanding their trade-offs will save you time, money, and headaches. Let’s cut through the noise and help you pick the perfect manufacturing path for your next robot part.

Understanding the Basics How CNC Machining and 3D Printing Work in Robotics

What Is CNC Machining and Why It Powers Robot Durability

Ever wonder why some robot parts last longer under stress while others fail quickly? The answer often lies in how they’re made. CNC machining is a subtractive manufacturing process that uses computer-controlled tools to cut away material from solid blocks—like metal or plastic—until the exact shape is formed. Think of it as sculpting the perfect robot part by carving it out with surgical precision.

Why does this matter for robot durability? Because CNC machining delivers superior strength and tight tolerances essential for high-load applications, like robotic arms or gears. When your robot needs to handle heavy weights or endure repeated movements, the parts must be flawless and tough. CNC machining ensures that by starting with solid, durable materials often used in industrial robots, including metals like aluminum, steel, and bronze alloys. This results in parts that don’t just fit perfectly but also withstand harsh operating conditions.

Plus, CNC machining offers excellent surface finishes, improving the performance and lifespan of components by reducing friction and wear. This precision manufacturing approach makes it a staple in the robotics industry for parts where reliability is critical.

If you’re curious about the types of CNC machines used in making robot parts and their specific roles, exploring resources about 3-axis CNC machines can offer deeper insight.

Micro takeaway: CNC machining is the go-to method for building robust, precise robot parts that need to endure high stress and deliver consistent performance.

Understanding the Basics How CNC Machining and 3D Printing Work in Robotics

What Is 3D Printing and How It Fuels Robot Innovation

3D printing, or additive manufacturing, builds robot parts layer by layer from digital designs. This method is a big deal in robotics because it powers rapid prototyping and lets engineers test new ideas quickly without the need for expensive tooling. Unlike traditional subtractive methods like CNC machining, 3D printing can create complex shapes that might be impossible or too costly to machine.

In the U.S., this means local manufacturers can move fast from concept to prototype, cutting lead times and reducing waste. It’s especially great for custom parts in drones or lightweight robot components where innovation trumps bulk production.

Key advantages of 3D printing in robotics include:

- Fast iteration on designs for testing new robot linkages or parts

- Making complex geometries that boost lightweight and efficient robots

- Using a wide range of materials, including plastics and some metals, for versatility

- Supporting low-volume runs without pricey setups

While 3D printing may not match CNC for durability or tight tolerances, it’s the go-to choice when you want to push boundaries and innovate in robot parts quickly and cost-effectively.

Precision and Tolerances Critical for Robot Functionality

When it comes to robot parts, precision isn’t just important—it’s essential. CNC machining is known for delivering tight tolerances and high repeatability, making it ideal for components like gears, shafts, and joints where every micron counts. The subtractive process allows for consistent accuracy, especially in metal machining for robotic arms, helping parts fit perfectly and function reliably under stress.

3D printing, on the other hand, offers good precision for rapid prototyping and complex designs but usually falls short of the tight tolerances CNC can achieve. Additive manufacturing works well for low-volume production or parts where slight dimensional variations won’t impact performance. However, surface finish and layer lines in certain 3D printed parts might require post-processing to meet demanding functional needs in robotics.

In short:

- CNC machining excels at precision prototyping and production where strict tolerances are critical.

- 3D printing is great for fast, flexible prototypes but may need extra steps to meet exact specifications.

If you want to dig deeper into how CNC machining handles tolerances for robot parts, check out this guide on robots parts machining.

Material Options Strength vs Versatility in Robotics

When picking between CNC machining and 3D printing for robot parts, the materials you can use play a big role. CNC machining works great with a wide range of metals like aluminum, steel, and titanium—materials known for their strength and durability. This makes it perfect for robot arms, gears, and other parts that need to handle heavy loads and high stress.

On the flip side, 3D printing offers more versatility with materials. You can print using plastics, composites, and even some metals, but the options aren’t always as tough as what CNC offers. This versatility lets you experiment with lightweight parts or complex shapes that would be tough or expensive to machine.

Key points:

- CNC machining: Best for strong, durable metals suited to industrial robots and high-stress components.

- 3D printing: Better for versatile materials including plastics and composites, ideal for rapid prototyping and custom parts.

- Material strength: CNC parts generally hold up better under stress.

- Material variety: 3D printing excels at mixing materials and creating intricate structures that support innovative robot designs.

Ultimately, if your robot part needs to be super sturdy and long-lasting, CNC machining is the way to go. But if you want to try new designs quickly or need lighter components, 3D printing offers more material flexibility.

Cost Breakdown Budgeting for Prototypes to Production Runs

When budgeting for robot parts, understanding the cost differences between CNC machining and 3D printing is crucial. Each method serves different financial needs depending on the project stage and volume.

CNC Machining Costs

- Setup and tooling: Higher upfront costs due to custom tools and machine setup.

- Material expense: Usually more costly because CNC uses solid blocks of durable metals or plastics.

- Economies of scale: Cost per part drops significantly for medium to high-volume production runs.

- Labor and operating costs: Skilled operation and maintenance add to the price but ensure tighter tolerances and better surface finishes, which matter in industrial robots.

3D Printing Costs

- Low initial investment: Minimal setup required, ideal for rapid prototyping and small batch jobs.

- Material variety and price: Uses polymers or metal powders, often cheaper but with some limits on strength and durability.

- Speed vs. cost: Faster turnaround for custom or complex geometries meaning less expense on design iterations.

- Scaling challenges: Costs don’t decrease as much with higher quantity, making it less cost-effective for large production runs.

Bottom Line for Robotics

- Use 3D printing when you need quick prototypes or custom robot parts with complex shapes—perfect for early development and testing phases.

- Choose CNC machining when producing durable, precise parts in larger quantities for final products or heavy-duty robot components.

- Sometimes a hybrid approach of both methods optimizes cost and performance, especially in robotics requiring both innovation and strength.

For building your budget wisely, knowing when to use each technology can save time and money from prototype through full production. Check out detailed cost and surface finish options in CNC at How to optimize your face milling process for high-quality robot parts.

Speed and Lead Times From Concept to Assembly Line

When it comes to getting robot parts from concept to the assembly line, speed and lead times vary a lot between CNC machining and 3D printing.

3D printing shines in rapid prototyping—you can go from design to a physical part in just a few hours or days. This makes it ideal for testing new ideas fast, especially when working on complex geometries or low-volume production robot frames. If you’re tweaking designs or building custom drone prototypes, the quick turnaround saves both time and money.

On the other hand, CNC machining usually takes longer upfront. Programming, setup, and tooling add time, especially for complex metal machining of robotic arms or parts needing tight tolerances. However, once the setup is done, CNC is much faster at producing high volumes of durable parts consistently. For large batch runs or high-load components, the speed of each cut outweighs the initial setup delay.

To sum it up:

- 3D printing offers faster lead times for prototyping and low-volume parts with more design freedom.

- CNC machining takes a bit longer upfront but speeds up during production runs, delivering precise, durable robot parts.

For many automation projects, combining the two methods helps hit deadlines without compromising quality.

Design Complexity and Scalability Unlocking Robot Geometries

When it comes to designing robot parts, complexity and scalability are major factors. CNC machining and 3D printing approach these differently, especially for the U.S. robotics market where innovation and production size vary a lot.

CNC machining excels with parts that need tight tolerances and smooth finishes but usually sticks to simpler shapes. Because it’s subtractive manufacturing, complex internal features or hollow sections are tough and costly to produce. Scaling up CNC production is solid — once the setup is done, it’s consistent and efficient for low to high volumes, making it great for durable robotic arms or gears.

On the other hand, 3D printing shines when creating intricate geometries that traditional machining can’t handle. Complex linkages, lattice structures, or integrated parts come to life quickly without extra tooling. For rapid prototyping of new robot designs, especially in the U.S. innovation hubs, 3D printing offers unmatched flexibility. Its scalability is different, though; low-volume and customized runs are easy, but mass production can get expensive or slow unless you use advanced additive manufacturing systems.

Here’s a quick comparison:

| Factor | CNC Machining | 3D Printing |

|---|---|---|

| Complex Shapes | Limited to simpler geometries | Supports highly intricate designs |

| Internal Features | Challenging and costly | Can create complex internal parts |

| Surface Finish | Smooth, precise | Often requires post-processing |

| Scaling Production | Efficient for low to high volumes | Best for low-volume, custom runs |

| Prototype Flexibility | Less flexible, longer setup | Rapid iterations, easy design changes |

In short, if you need durable, precise parts in volume, CNC machining handles scalability better. If your robot design demands complexity and quick changes, 3D printing unlocks more possibilities. For many U.S. robotics manufacturers, a hybrid approach combining both helps get the best of both worlds.

Pros and Cons Tailored to Robot Applications

When deciding between CNC machining vs 3D printing for robot parts, it helps to weigh their strengths and weaknesses based on what your project needs. Here’s a quick breakdown:

CNC Machining Pros

- Durability: CNC parts are made from solid blocks of metal or plastic, offering strong, reliable materials ideal for industrial robots and heavy-duty components.

- Precision: Tight tolerances are possible, which is critical for gears, joints, and parts where exact fit matters.

- Surface Finish: CNC can deliver smooth finishes right off the machine, reducing the need for extra post-processing.

- Material Variety: Works with a wide range of metals and engineering plastics, offering strength and performance options.

CNC Machining Cons

- Cost: Higher setup costs and tooling expenses can make low-volume runs pricey.

- Design Limits: Complex internal geometries are tough since material is removed, not added.

- Lead Times: Can take longer for prototypes since each part must be machined individually.

3D Printing Pros

- Design Freedom: Easily create complex shapes, lightweight structures, and custom parts without added cost.

- Speed: Rapid prototyping accelerates iteration cycles, great for testing new concepts fast.

- Cost-Effective Prototypes: Lower upfront cost for low-volume or one-off components.

- Material Innovation: Advanced polymers and metal powders allow innovative lightweight and flexible parts.

3D Printing Cons

- Strength: Generally not as strong or durable as CNC-machined metal parts, which can limit use in high-load applications.

- Tolerance Limits: Finer precision is improving but often falls short of CNC standards for critical fits.

- Surface Quality: Printed parts usually need extra finishing to smooth out rough surfaces and improve appearance.

Bottom line for U.S. Robotics Makers

- Use CNC machining when strength, precision, and material performance are top priorities, especially for industrial robots or parts under heavy stress.

- Choose 3D printing for rapid prototyping, complex geometries, or custom drone components where agility and innovation matter more.

- Consider a hybrid approach combining both methods to balance durability with design freedom and cost savings.

This way, you get the best of both worlds while keeping your robot projects on track and within budget.

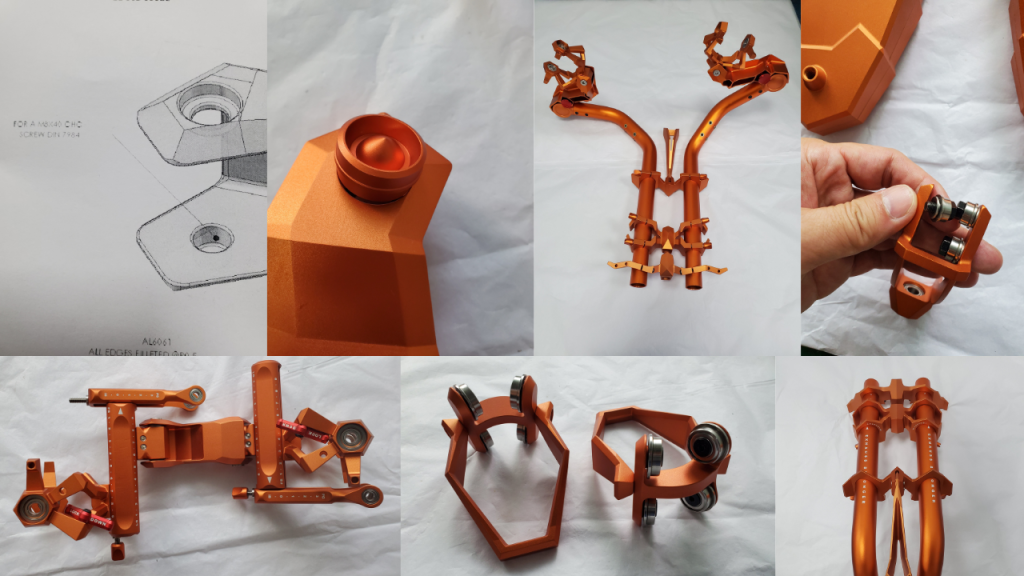

Real-World Case Studies XTJ Precision Mfg’s Robot Projects

Case Study 1 CNC for a High-Load Robotic Gripper

At XTJ Precision Mfg, we’ve seen how CNC machining truly shines when building parts like high-load robotic grippers. These components need to handle heavy forces and repeated stress without failing — something CNC machining is built for. By using metal machining for robotic arms with tight tolerances, we create parts that are strong, durable, and precise.

For this project, XTJ relied on CNC machining with aluminum and steel alloys, chosen for their strength and wear resistance. The process allowed us to hit exact tolerances in CNC robot gears and maintain consistent quality, which is critical for gripping mechanisms that must move smoothly and securely under high loads.

Key benefits we delivered:

- High precision for complex gear teeth and joint surfaces

- Superior surface finish critical to smooth movement and longevity (visit our guide on surface finishes for more details)

- Material strength to withstand industrial environments and stress

- Repeatability for batch manufacturing of identical gripper parts

This case shows that for heavy-duty, load-bearing robot parts, CNC machining remains the top choice—combining reliability, precision, and durability in ways that rapid 3D printing can’t match just yet.

For more about CNC machining capabilities and how they power tough robot parts, check out our Aluminum CNC Machining Services.

Case Study 2 3D Printing for Custom Drone Prototypes

At XTJ Precision Mfg, we’ve seen how 3D printing really shines when it comes to making custom drone prototypes. Unlike traditional methods, additive manufacturing lets us quickly build complex drone parts without the need for expensive tooling or long lead times. This means faster iteration and testing, which is key when you’re refining drone designs.

Here’s what makes 3D printing a go-to for drone prototyping:

- Rapid turnaround lets teams go from design to physical part in days, not weeks

- Design flexibility supports intricate shapes and lightweight structures that CNC can’t easily create

- Cost savings on low-volume, custom parts keep the budget in check while working out the kinks

- Material variety includes durable plastics and some metal options, tailored to drone frames and linkages

One recent XTJ project involved 3D printing a drone chassis with integrated mounting points and internal channels for wiring—something traditional machining would have made slower and more costly. The parts came out strong enough for field testing and adjustments, helping our client move to production faster.

In short, for precision prototyping in robotics like drones, 3D printing offers incredible speed, versatility, and cost-effectiveness, especially when you need to test multiple design tweaks quickly. It’s a perfect complement to CNC machining in the robotics manufacturing world.

When to Choose CNC 3D Printing or Both for Your Robot Parts

Deciding between CNC machining and 3D printing for your robot parts depends on what your project needs most. Sometimes, the best solution is actually using both to get the most out of each method.

Choose CNC Machining When:

- You need strong, durable parts that can handle high loads and wear, like gears or robotic arms.

- Precision and tight tolerances are critical for your robot’s function.

- The material options need to include metals like aluminum or stainless steel for long-lasting use.

- You’re planning medium to high volume runs where repeatability matters.

- A smooth surface finish is essential, especially for moving parts or joints.

Choose 3D Printing When:

- Rapid prototyping or low-volume production is your priority.

- Your design has complicated geometries that are tough to machine, like intricate linkages or lightweight frames.

- You want to experiment with different designs quickly without tooling costs.

- Using versatile materials such as flexible plastics or resins fits your robot application.

- Speed from design to assembly is critical for innovation cycles.

Combine Both for Best Results

- Start with 3D printing for early prototypes to test form and fit.

- Move to CNC machining for final parts that require strength and precision.

- Use 3D printing for customized or complex components while machining structural parts.

- Hybrid manufacturing taps into the advantages of additive and subtractive processes, optimizing cost and performance.

This hybrid approach is increasingly popular in the U.S. robotics market, especially for companies aiming to balance precision prototyping with durable, high-performance parts. If you want to learn more about how CNC machining benefits robotic arms and other components, check out our key benefits of CNC machining page.

The Future of Manufacturing Robot Parts Trends and Innovations

Looking ahead, the way we make robot parts is evolving fast. Both CNC machining and 3D printing are pushing boundaries, and the future lies in blending their strengths for better results. Here’s what to watch for in the coming years:

- Hybrid Manufacturing: Combining subtractive methods like CNC with additive 3D printing. This hybrid approach offers durable, precise parts with complex shapes, perfect for automation and robotics.

- Advanced Materials: Expect new metal alloys and composite materials designed specifically for robotics. These will boost strength, reduce weight, and improve durability for industrial robots and custom frames.

- Faster Prototyping and Production: Rapid 3D printing technologies will speed up prototype development, while CNC machining will continue to support high-volume runs with tight tolerances. Together, this cuts design-to-assembly times.

- Improved Surface Finishes: 3D printing is catching up with CNC in producing smoother surfaces. This means less post-processing is needed for robot parts like gears and linkages, saving time and cost.

- AI and Machine Learning Integration: Smart machines will optimize both CNC and 3D printing processes, improving precision and reducing waste for robot components.

For U.S. manufacturers and designers, staying ahead means adopting these trends to make robot parts that are both cost-effective and built to last. Whether you need low-volume custom prototypes or durable production runs, the future of robot manufacturing is about flexibility and innovation.