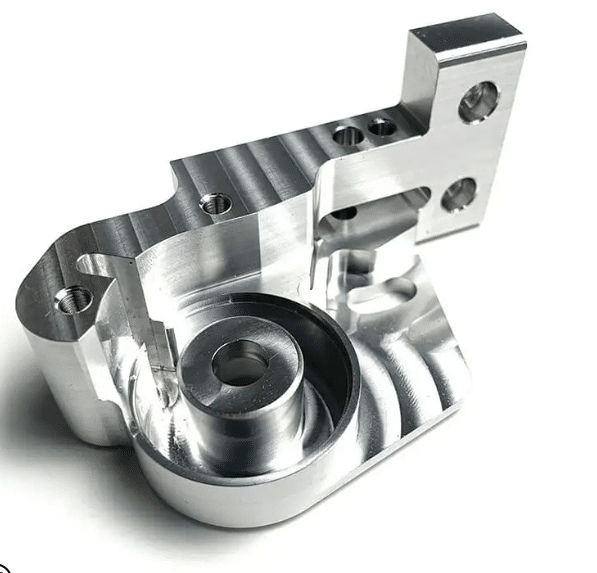

Aluminum 6061 Parts CNC machining Factory

If you Want to find a cost-effective manufacturer of custom precision aluminum parts? XTJ is a CNC machining company with years of experience, capable to process turning and milling 6061 aluminum of almost any complexity for a wide variety of purposes and industries. Take a look at our precision OEM CNC milling aluminum parts for machines, get an instant free quote online. 6061 is a popular grade in the aluminum alloy family due to its high corrosion resistance, good formability, and weldability. 6061-T6 aluminum refers to the aluminum alloy that has been given a solution heat treatment followed by quenching, cooling, and aging. T6 is a commonly applied version of 6061 aluminum and offers a good strength-to-weight ratio and can be used to make bicycle frames, fly fishing reels, fire department rescue ladders, and more applications that require strength and toughness. XTJ is growing faster in the CNC manufacturing industry because of exceptional quality, machining capabilities, custom design, and quick delivery. Our engineers, designers, sales, and quality teams always strive to exceed the requirements of customers.

Advantages Of Our OEM CNC Milling 6061-T6 Aluminum Aircraft Airplane Parts

– ISO 9001 quality certificated and complete quality management system

– In-depth knowledge and understanding of material, fabrication, and industry

– Advanced manufacturing facilities, rich experience, and strong capabilities

– Best OEM service provides the most cost-effective products with high standard

Specifications Of OEM CNC Milling 6061-T6 Aluminum Aircraft Parts

| Material | Aluminum 6061-T6 |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Machine Parts |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.