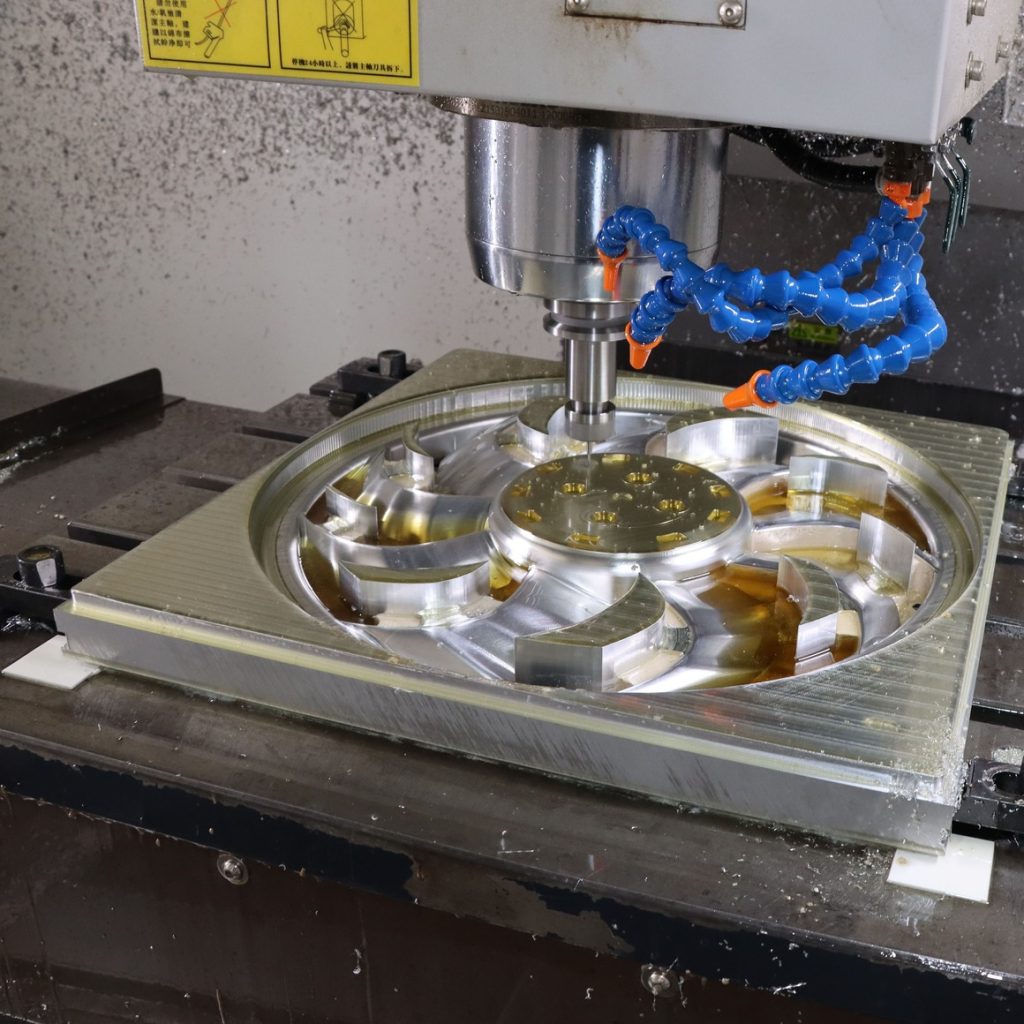

High-Quality CNC Milling Services

Based in China,

we offer competitive pricing and fast lead times to bring your projects to life.

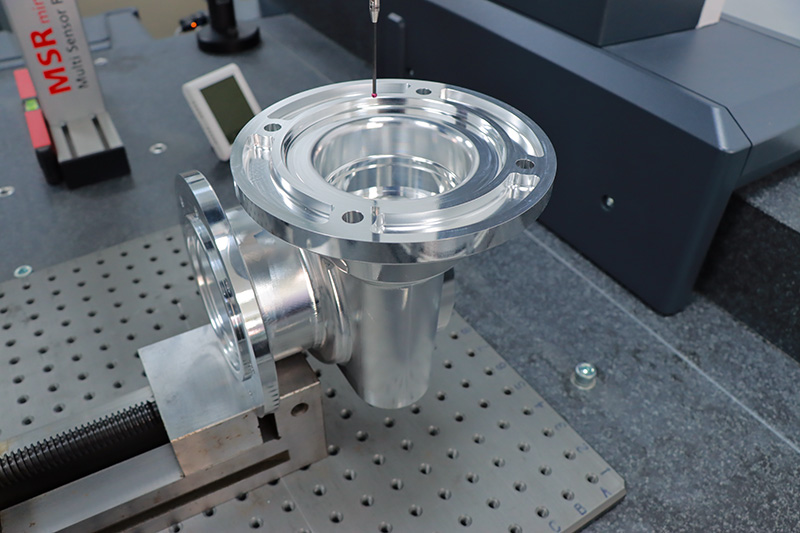

- ±0.005 mm Tight Tolerances with Zeiss CMM Inspection

- Custom Finishes to Meet Your Specifications

- Lead Times from 5 Days for Rapid Delivery

- Secure Data Handling for Your Peace of Mind

Expert CNC Milling Services for Every Industry

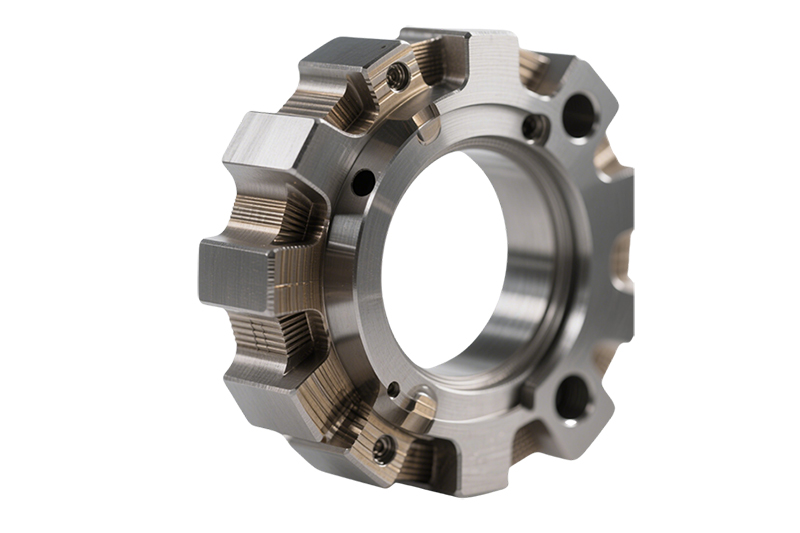

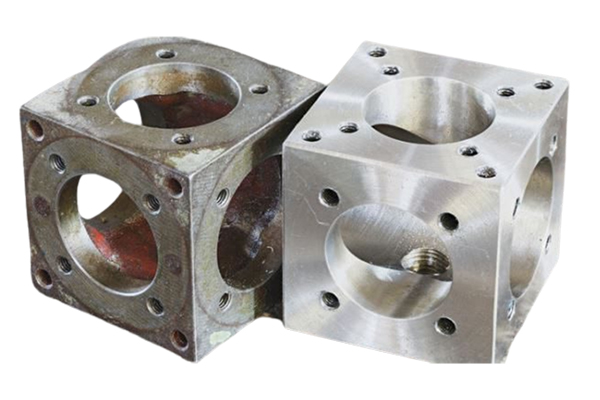

At XTJ Machining, we specialize in delivering precision-machined parts with exceptional quality. Our 100+ advanced CNC milling machines enable us to handle projects of any scale, from prototypes to high-volume production, ensuring precision CNC milling for all your needs.

Why Choose XTJ for CNC Milling?

Affordable Pricing

Industry-leading low-cost CNC milling services, saving you more without compromising quality.

High-Volume Capacity

Over 100 cutting-edge CNC milling machines ensure fast production and scalability.

Rapid Turnaround

Efficient workflows deliver most projects within 5-10 business days.

Unmatched Precision

Tolerances as tight as ±0.005 mm, verified by Zeiss CMM inspection equipment.

Material Expertise

We mill aluminum, steel, titanium, brass, plastics, and more to meet your needs.

What is CNC Milling?

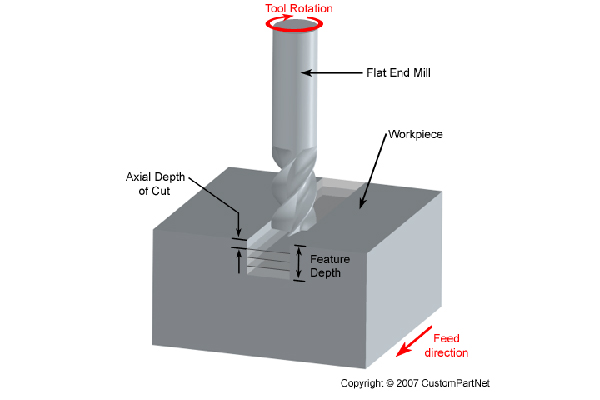

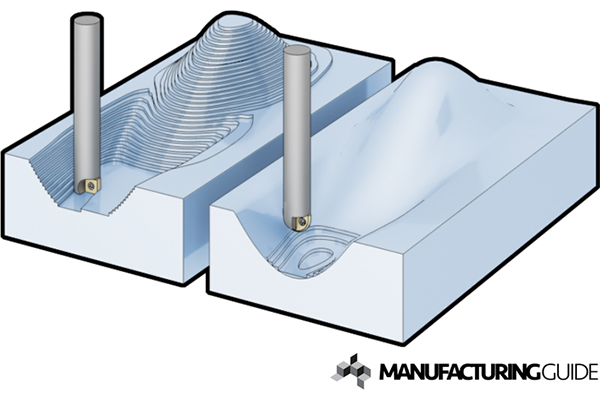

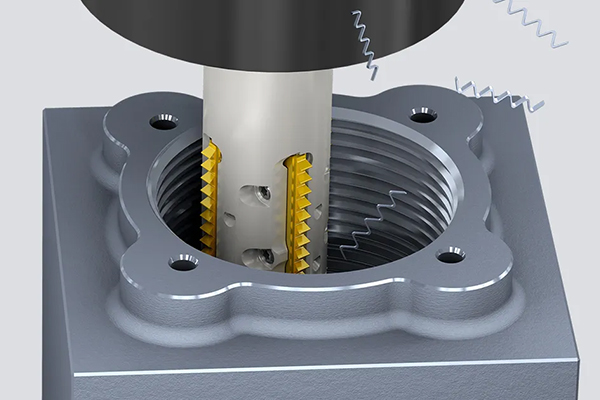

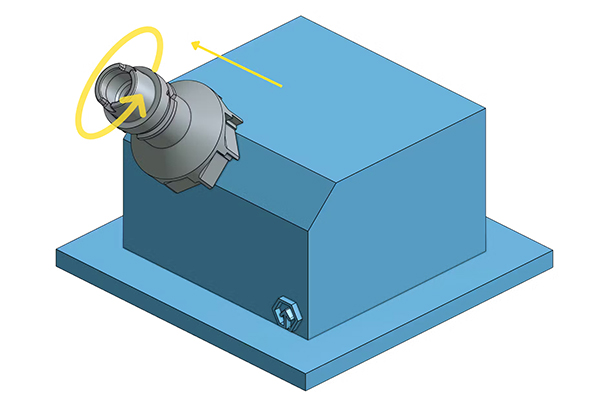

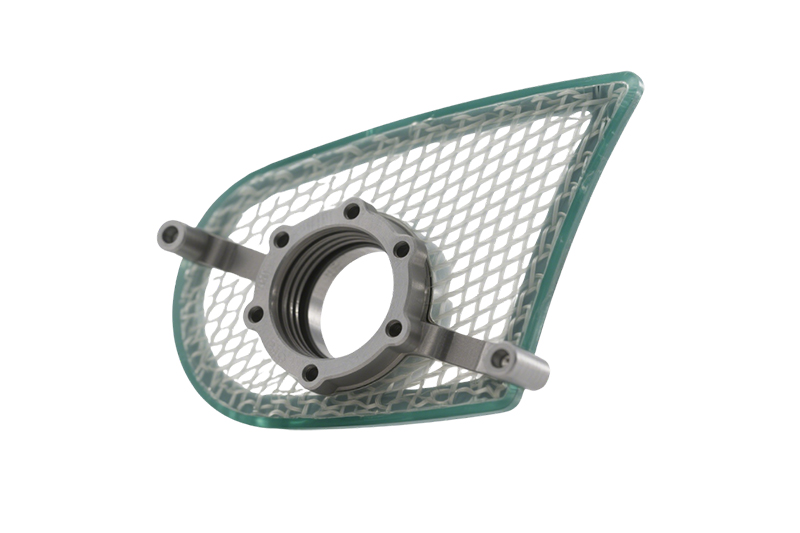

CNC milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece. Rotating cutting tools create precise features like slots, holes, threads, and complex contours. At XTJ, we provide 3-axis, 4-axis, and 5-axis CNC milling to produce parts ranging from simple flat surfaces to intricate 3D geometries, ensuring versatility for your designs.

Types of CNC Milling Operations at XTJ

We offer a range of CNC milling techniques to suit different project requirements:

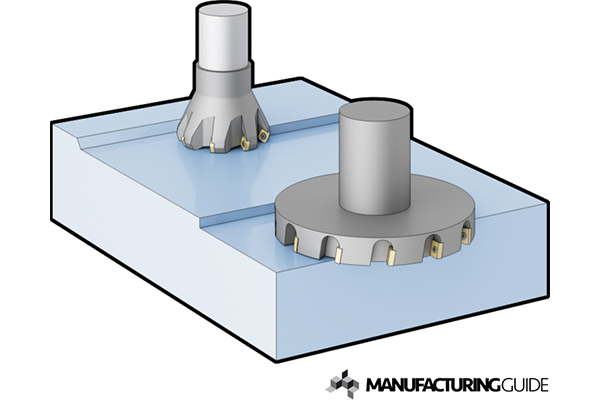

Face Milling

Creates flat surfaces and smooth finishes, ideal for large, even areas.

End Milling

Produces slots, pockets, and contours using the side and end of the tool.

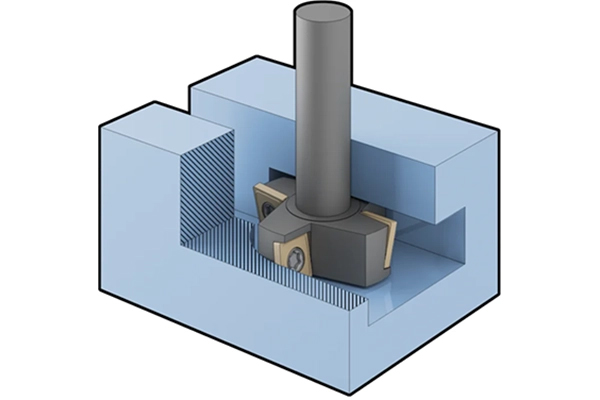

Slot Milling

Cuts narrow channels or slots into the workpiece for functional or aesthetic purposes.

Profile Milling

Shapes the outer contours of a part, often used for complex geometries.

Thread Milling

Machines internal and external threads with precision for fasteners and fittings.

Angular Milling

Creates angled features like chamfers or dovetails for specialized components.

Materials and Surface Finishes Supported by XTJ Machining

Varies by material type, generally high hardness. Tool selection and cutting parameters should be based on specific composition, with attention to wear resistance and thermal stability.

Aluminum (e.g., 6061, 7075)

Characteristics: Lightweight, good thermal conductivity, easy to machine, chips break easily. May cause tool sticking; requires proper cooling and lubrication. Suitable for high-speed milling.

Steel (e.g., stainless, carbon)

Characteristics: High hardness, wear-resistant, but generates high cutting forces and heat during machining. Requires low-speed milling with hard tools (e.g., carbide). Stainless steel may exhibit work hardening.

Titanium

Characteristics: High strength, low thermal conductivity, heat concentrates during machining, causing tool wear. Requires low-speed cutting, high-performance tools, and sufficient cooling.

Brass

Characteristics: Soft and easy to machine, good machinability, chips break easily, high surface finish. Suitable for high-speed milling, generates less heat.

Copper

Characteristics: High thermal conductivity, ductile, prone to tool sticking during machining. Requires sharp tools and proper lubrication. Chips may be long, so chip removal is important.

ABS

Characteristics: Good toughness, easy to machine, but prone to softening from heat. Requires controlled cutting speed and cooling to avoid melting or burrs.

POM (Polyoxymethylene)

Characteristics: Moderate hardness, wear-resistant, self-lubricating, stable during machining, good surface finish. Be cautious of thermal deformation.

PEEK

Characteristics: High temperature resistance, chemical resistance, high hardness. Requires hard tools, generates high cutting forces, and needs temperature control to prevent deformation.

Polycarbonate

Characteristics: Transparent, high toughness, but prone to stress cracking. Requires low-speed cutting to avoid overheating, and sharp tools are necessary.

Nylon

Characteristics: High toughness, wear-resistant, but hygroscopic and prone to deformation during machining. Requires controlled cutting speed, suitable for low-speed milling.

Carbon Fiber

Characteristics: High strength, lightweight, but very hard. Prone to delamination or burrs during machining. Requires diamond or carbide tools, and dust protection is necessary.

Fiberglass

Characteristics: High hardness, corrosion-resistant, but abrasive to tools and generates dust during machining. Requires efficient dust extraction and hard tools.

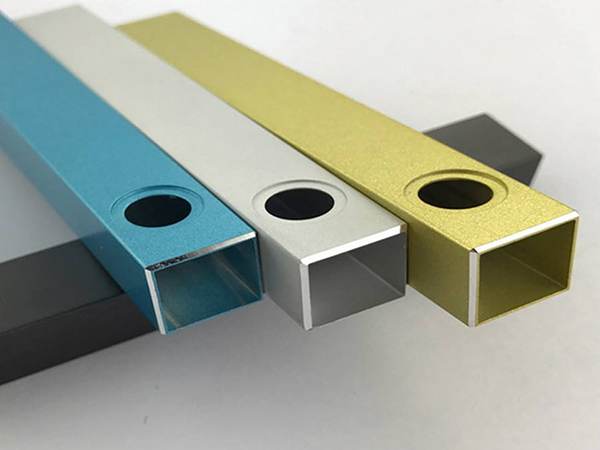

Elevate Your Parts with Advanced Surface Finishing

Enhance the durability, functionality, and aesthetics of your components with XTJ’s range of surface finishing options. Each process is tailored to meet specific performance and design requirements, ensuring your parts not only perform exceptionally but also look their best.

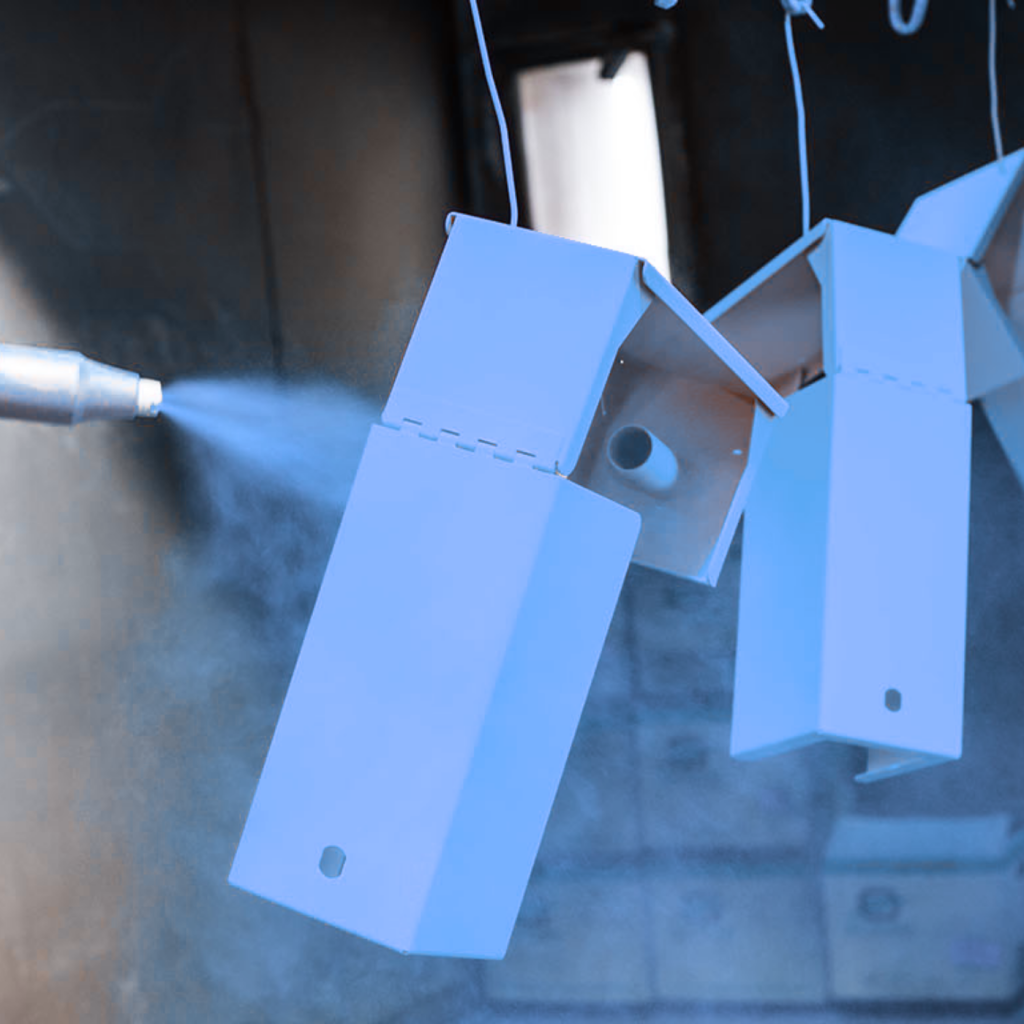

Durable and Versatile Coating for Long-Lasting Protection

Powder coating applies a dry powder—typically a mix of resin and pigment—electrostatically to the part, which is then cured under heat to form a tough, protective layer. This finish is known for its durability and resistance to chipping, scratching, and corrosion.

Durable and Versatile Coating for Long-Lasting Protection

Powder coating applies a dry powder—typically a mix of resin and pigment—electrostatically to the part, which is then cured under heat to form a tough, protective layer. This finish is known for its durability and resistance to chipping, scratching, and corrosion.

Uniform Matte Finish for Enhanced Aesthetics

Bead blasting uses small glass beads propelled at high pressure to create a consistent, non-reflective matte finish on the surface of parts. This process removes surface imperfections and provides a clean, uniform texture.

Mirror-Like Finish for Premium Applications

Polishing involves mechanically smoothing the surface of a part to achieve a high-gloss, mirror-like finish. This process enhances both the visual appeal and the tactile quality of the component.

Enhanced Corrosion Resistance for Stainless Steel

Passivation is a chemical treatment that removes free iron from the surface of stainless steel parts, forming a passive oxide layer that significantly improves corrosion resistance.

XTJ’s CNC Milling Capabilities

Multi-Axis Options: 3-axis, 4-axis, and 5-axis milling for simple to complex geometries.

Tolerances: As tight as ±0.005 mm for precision applications.

Part Size: From small components to parts up to 1000 mm x 800 mm x 600 mm.

Production Flexibility: From single prototypes to thousands of parts, we handle it all.

Advanced Equipment: High-speed spindles, modern tooling, and 100+ machines for superior efficiency.

Our CNC Milling Process

Collaborate with us effortlessly: Submit your design, get expert feedback, approve your quote, and launch production. Stay informed at every stage for reliable, high-quality outcomes.

XTJ’s Commitment to Quality

At XTJ Machining, quality is our priority. We use world-class inspection tools like the Zeiss CMM to ensure every part meets the highest standards. Our strict tolerance control and thorough quality assurance processes make us a reliable choice for CNC milling services worldwide.

Frequently Asked Questions (FAQs)

We mill a wide range of materials, including aluminum, steel, titanium, brass, and plastics. Contact us to discuss the best material for your project.

We achieve tolerances as tight as ±0.005 mm, ensuring precision for even the most demanding applications.

With over 100 machines, we offer fast lead times—most projects are completed within 5-10 business days, depending on complexity.

Yes, we provide finishes like anodizing, powder coating, and bead blasting to enhance the durability and appearance of your parts.

Absolutely! Our large-scale production capacity ensures we can manage high-volume orders efficiently while maintaining quality.

Have More Questions? Reach Out to XTJ for Expert Advice

Looking for reliable, affordable CNC milling services? Partner with XTJ Machining for precision, efficiency, and unbeatable value. Contact us now to discuss your project and get a free quote.