CNC Router Services by XTJ Precision Mfg

Get a quote for customized parts through our CNC Router Services for rapid prototyping and production parts in as little as 5 days.

- Custom CNC Signs & Logos

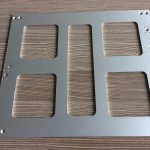

- Custom CNC Parts

- CNC Wood Services

- RTA Cabinet Parts

CNC Router services & XTJ Precision Mfg

As a branded supplier of parts manufacturing with over 20 years of experience in the CNC field, XTJ Precision Mfg has become the go-to resource for businesses and individuals looking for high-quality CNCRouter Services solutions for the production of components as well as finished products, thanks to our expertise, cutting-edge technology, and commitment to quality.

XTJ prides itself on delivering the best quality solutions to our customers, and by partnering with us you not only gain access to state-of-the-art technology, but also a dedicated team of craftsmen and designers to assist you throughout the process. From start to finish, you and your product will be treated with the same care as our own.

What Is CNC Router

CNC Router is a subtractive manufacturing process that begins with a digital design (CAD file), converted into machine instructions via CAM software. Computer Numerically Controlled (CNC) machine tools are used to cut, carve and shape materials such as wood, plastics, metals and composites. materials such as wood, plastic, metal and composites. A rotating milling head guided by precise digital instructions (G-codes) creates accurate cuts, holes, and intricate patterns in flat surfaces or plates.

Our CNC Router services Capabilities

Our machine cutting tolerances are (+/-0.002″ for plastics and +/-0.005 for most woods. The natural expansion and contraction of wood may make very tight tolerances unnecessary)

- Cutting of most sheet products

- Small and large quantities (1-10,000)

- Solid Wood Products

- Customized Tools

- Fast, easy to use and reliable

- Wood, acrylic and vinyl cutting

CNC Router vs. Other CNC Processes

CNC router shares similarities with CNC milling and CNC turning but differs in several ways:

| Category | Essential difference |

|---|---|

| Cutting Tool | CNC routing uses a rotating router bit, while CNC milling employs multi-point end mills, and CNC turning uses single-point tools for cylindrical parts. |

| Material Orientation | CNC routing is optimized for flat materials like wood panels or plastic sheets. CNC milling processes block or prismatic workpieces, and CNC turning focuses on cylindrical components. |

| Cutting Direction | CNC routing primarily cuts in the X-Y plane for 2D or 2.5D designs. CNC milling and turning support multi-axis movements for complex 3D shapes. |

| Applications | CNC routing excels in woodworking, signage, and cabinetry. CNC milling is used for precision parts in aerospace or automotive industries, while CNC turning produces rotational components like shafts. |

Our team has all the experience needed to complete your custom fabrication project from start to finish.

CNC Router services common materials

Our industrial-grade CNC router machines are suitable for a wide range of materials – plastics, plywood, hardwoods, laminates, and more – and are perfect for providing customized cuts. Below is a list of some of the most commonly used materials at CNC router services:

- Brass

- Composites

- PVC

- ABS

- acrylic

- most other plastics.

- Hardwood

- Softwood

- Plywood

- Fiberboard

- Particle board

- Other wood

- HDPE (High-Density Polyethylene)

- MDF (Medium-Density Fiberboard)

- Polycarbonate

- Foam

- UHMW (Ultra-High Molecular Weight Polyethylene)

- Aluminum

Ready to Start Your CNC Routing Services Project?

Upload your design for a free quote or connect with our team to discuss your needs.