CNC Steel Machining Services

CNC Machining of Steel Alloys for Custom Parts and Prototypes

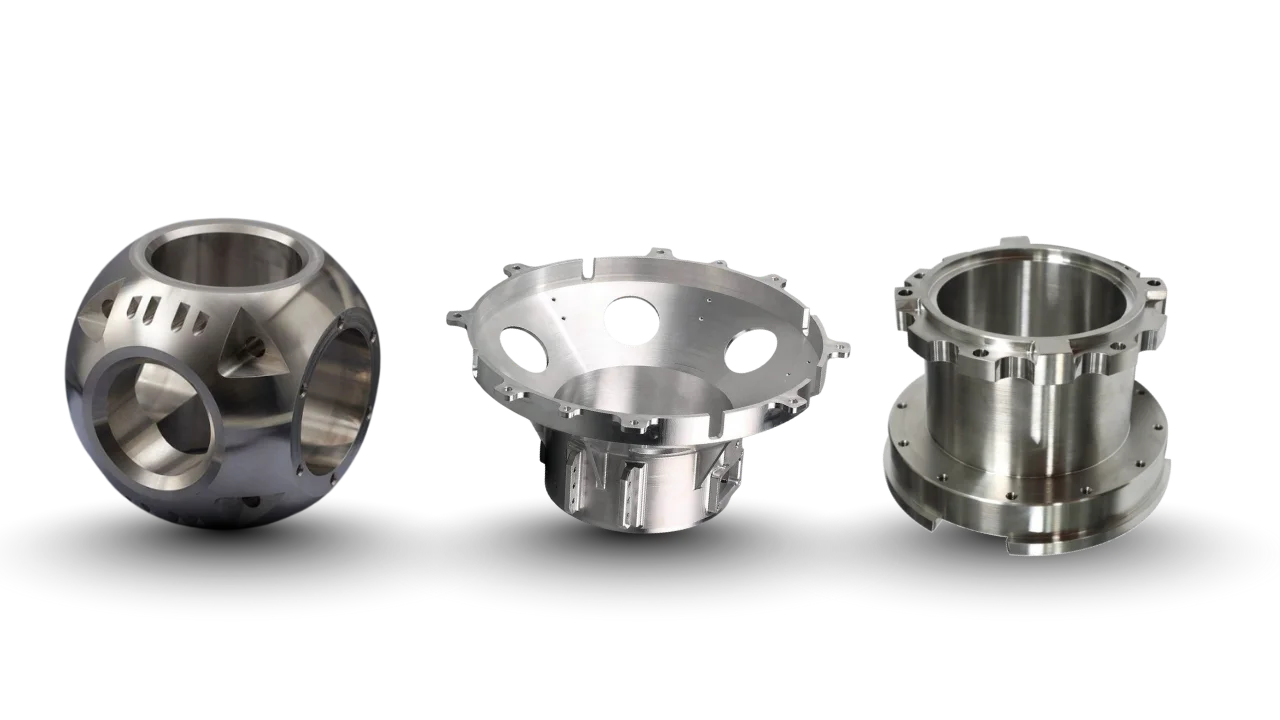

- Precision machining for intricate designs

- Flexible solutions for diverse industries

- Lead Times from 5 Days for Rapid Delivery

- Tailored services to meet unique requirements

we specialize in high-precision CNC steel machining, delivering custom parts that offer unmatched strength, durability, and versatility.

Why Choose Steel for CNC Machining?

Steel, primarily an iron-carbon alloy with up to 2% carbon and optional alloying elements like chromium or nickel, is the backbone of modern engineering due to its remarkable strength-to-weight ratio and adaptability. It outperforms many metals in load-bearing scenarios, providing a cost-effective alternative to exotic materials while maintaining reliability in extreme conditions. Compared to softer alloys like aluminum, steel’s higher hardness enables longer-lasting parts but demands optimized machining to manage tool wear and heat.

High Strength and Hardness

Withstands heavy loads and impacts, ideal for structural and mechanical components.

Wear Resistance

Excels in abrasive environments, reducing downtime and replacement needs.

Versatility

Easily heat-treated for tailored properties, from ductile to ultra-hard.

Cost-Effectiveness

Abundant and recyclable, offering excellent value for high-volume production.

Corrosion Options

Alloyed variants like stainless steel provide protection in harsh settings.

Our CNC expertise harnesses these traits to create parts with precise geometries and minimal defects, surpassing casting or forging in speed and accuracy for complex designs.

Steel Material Properties

Steel alloys are engineered by varying carbon content (0.05–2%) and additives, customizing traits for specific demands. Typical properties include:

- Density: 7.8–8.0 g/cm³, delivering robust yet manageable weight.

- Hardness: Rockwell B 70–100 (up to C 60 in tool steels), balancing toughness and edge retention.

- Tensile Strength: 400–2,000 MPa, scalable via grade and treatment.

- Elongation: 5–50%, supporting formability in low-carbon types.

- Maximum Service Temperature: Up to 1,000°F in heat-resistant alloys.

These qualities position steel as a staple for parts needing superior mechanical performance and environmental adaptability.

Available Steel Grades for Machining

We maintain a comprehensive inventory of steel alloys for your CNC projects. Below is a curated list of popular grades, highlighting essential specifications:

| Alloy | Machinability Rating (AISI) | Tensile Strength | Hardness | Key Features | Typical Uses |

|---|---|---|---|---|---|

| 1018 (Low Carbon Steel) | 70–80 | 440 | B 71 | Excellent ductility, weldable, easy to form | Shafts, pins, structural brackets |

| 1045 (Medium Carbon Steel) | 60–70 | 515 | B 86 | Balanced strength, heat-treatable for hardness | Gears, crankshafts, machinery parts |

| 4140 (Alloy Steel) | 50–60 | 655–1,000 | C 22–30 | High toughness, fatigue-resistant, good corrosion resistance | Axles, bolts, aerospace components |

| 304 (Austenitic Stainless) | 45–55 | 505 | B 70 | Superior corrosion resistance, non-magnetic | Valves, fittings, food processing equipment |

| 316 (Austenitic Stainless) | 40–50 | 550 | B 80 | Enhanced pitting resistance, biocompatible | Marine hardware, medical implants, chemical tanks |

Note:All grades conform to ASTM standards for reliability. Consult our team for specialized options like 17-4PH for precipitation hardening or H13 tool steel for high-heat applications.

Our CNC Steel Machining Processes

From our ISO-certified shop, we deploy cutting-edge 3- and 5-axis CNC mills, lathes, and Swiss machines to tackle simple brackets to multifaceted assemblies. Steel’s varying hardness—from soft low-carbon to tough stainless—calls for tailored strategies: high-speed steel or carbide tools, feeds of 0.001–0.006 in/rev, and high-pressure coolants to combat work hardening and chip buildup.

Secondary operations such as heat treating, passivation, or zinc plating boost durability and aesthetics. Prototypes ship in 3–5 days, with streamlined scaling for larger orders.

Tolerances and Precision Standards

Excellence in precision defines us. We adhere to ISO 2768-m standards (±0.005–0.010 mm), refining to ±0.001 mm using CMMs and laser scanners. Alloy hardness and part dimensions affect outcomes—low-carbon steels like 1018 yield tighter specs with less expansion.

Applications of CNC Machined Steel Parts

Automotive & Aerospace

Crankshafts, landing gear, and turbine components enduring vibration and stress.

Energy & Marine

Pressure vessels and propeller shafts resisting corrosion and pressure.

Medical & Food Processing

Implants and sanitary fittings leveraging stainless hygiene and strength.

Tooling & Consumer Goods

Dies, knives, and hardware blending performance with economy.

Automotive & Aerospace

Crankshafts, landing gear, and turbine components enduring vibration and stress.

Steel Machining FAQs

Drawing from our deep knowledge at XTJ Precision Manufacturing, here are responses to frequent queries on CNC steel machining.

Steel machinability varies by grade—low-carbon like 1018 is straightforward with good chip formation, while high-carbon or stainless types demand slower speeds to avoid hardening.

1018 mild steel tops for ease, scoring 70–80 on machinability scales due to its softness and ductility; for stainless, 303 excels with sulfur additives for smoother cuts.

Yes, CNC excels at steel with robust tooling and cooling, handling everything from milling to turning for precise, repeatable results on complex parts.

Carbon steel prioritizes raw strength and affordability but rusts easily, while stainless adds chromium (10%+) for corrosion resistance at a higher cost and machinability challenge.

Essential, especially for stainless or alloy steels, to dissipate heat, prevent galling, and extend tool life—high-pressure systems are standard in our operations.

Higher density increases weight and machining time versus aluminum, plus potential warping from heat treatment; however, its strength justifies use in demanding roles.

Get Your Custom Steel Parts Today

Harness the reliability of CNC steel machining with XTJ—upload your designs for an instant quote or discuss alloy selection with our experts. We deliver precision, speed, and value every step of the way.