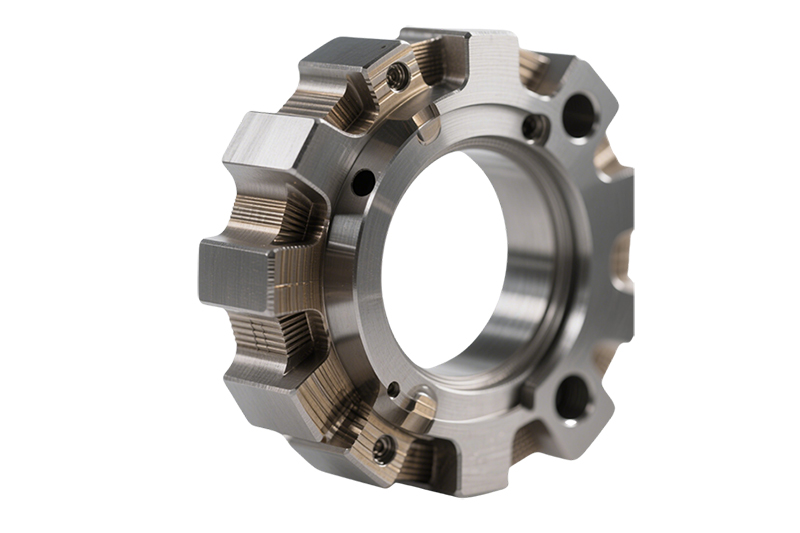

Precision CNC Turning Services

Trusted CNC Turning Solutions,Based in China, we offer competitive pricing and fast lead times to meet your manufacturing demands.

- Data Security to Safeguard Your Designs

- Over 100 CNC Machines for High Efficiency

- Lead Times from 5 Days for Quick Turnaround

Expert CNc Turning Services for Your Projects

At XTJ Machining, we excel in precision CNc turning to produce high-guality cylindricalcomponents. With over 100 advanced CNC turning machines, we deliver cost-effectivesolutions, fast turnarounds, and exceptional accuracy for prototypes and large-scaleproduction.

we handle projects from simple components to complex designs. Serving industries like aerospace, automotive, and medical, XTJ delivers fast, reliable, and top-quality parts, making precision manufacturing accessible and efficient for your needs.

Why Choose XTJ for CNC Turning?

Competitive Pricing

Our CNC turning services offer exceptional value through cost-effective solutions without compromising quality. By leveraging advanced technology, optimized processes, and strategic sourcing, we deliver precision-engineered components at prices that lead the industry. Whether you’re a small business or a large-scale manufacturer, our commitment to affordability ensures you receive top-tier service tailored to your budget, making us the preferred choice for high-quality, low-cost CNC turning solutions.

High Production Capacity

At XTJ, our cutting-edge facility boasts over 100 advanced CNC machines and more than 40 precision lathes, ensuring unmatched scalability and rapid delivery for projects of any size. This extensive equipment lineup empowers us to efficiently manage high-volume production, intricate designs, and tight deadlines with consistent quality. Whether you need small-batch prototypes or large-scale manufacturing, XTJ’s robust capacity and streamlined operations deliver reliable, high-performance CNC turning solutions tailored to your needs, making us your trusted partner for superior results.

Superior Precision

we deliver exceptional accuracy with tolerances as tight as ±0.005 mm, ensuring components meet the most stringent specifications. Our precision is validated through rigorous inspections using state-of-the-art Zeiss Coordinate Measuring Machines (CMM), guaranteeing unparalleled quality and consistency. Whether for aerospace, medical, or high-tech industries, our advanced CNC turning capabilities and meticulous quality control processes provide reliable, high-precision solutions that exceed expectations, making XTJ the preferred choice for mission-critical applications.

Material Versatility

our expertise spans a wide range of materials, including aluminum, stainless steel, brass, titanium, and various plastics, ensuring tailored solutions for diverse applications. Our skilled team and advanced CNC turning capabilities allow us to handle each material’s unique properties with precision and efficiency, delivering high-quality components for industries like aerospace, automotive, medical, and more. Whether you require lightweight alloys, corrosion-resistant metals, or durable plastics, XTJ’s versatile material proficiency guarantees optimal performance and reliability for your project needs.

CNC Turning Design Reference

This guide, developed by our turning experts, provides ideal specifications for crafting precise turned components. It includes recommended measurements and feasible limits to guide your production process.

| Component | Ideal Measurement | Acceptable Limit |

|---|---|---|

| Smallest Feature | Ø 2.0 mm | Ø 0.4 mm |

| Internal Radii | R 7 mm | R 0.3 mm |

| Thinnest Section | 0.7 mm (metals) / 1.4 mm (plastics) | 0.4 mm (metals) / 0.9 mm (plastics) |

| Diameter: Ø 0.6 mm / Depth: 12x diameter | Diameter: standard tools / Depth: 5x diameter | Diameter: Ø 0.6 mm / Depth: 12x diameter |

| Thread Standards | Size: M5 or larger / Length: 4x diameter | Size: M2 / Length: 2x diameter |

CNC Turning Tolerance Guide

Developed by our precision engineering team, this reference outlines standard tolerances for CNC turning projects, adhering to ISO 9001 standards. Our advanced lathes ensure accuracy from medical devices to industrial components, with tolerances as tight as ±0.005 inches.

| Component | Tolerance Range |

|---|---|

| Length Measurement | ± 0.03 mm / ± 0.0012 inch |

| Bore Sizes (unreamed) | ± 0.03 mm / ± 0.0012 inch |

| Shaft Sizes | ± 0.03 mm / ± 0.0012 inch |

| Component Dimensions | 900 * 550 * 480 mm |

| Component Dimensions | 35.4 * 21.7 * 18.9 inch |

Need a Specific Turning Operation?

Types of CNC Turning Operations at XTJ

We provide a variety of turning techniques to meet your needs:

Straight Turning

Shapes the external diameter of a workpiece for uniform cylinders.

Taper Turning

Creates conical shapes for specialized components.

Threading

Machines internal and external threads for screws and fittings.

Facing

Smooths the end face of a part for a clean finish.

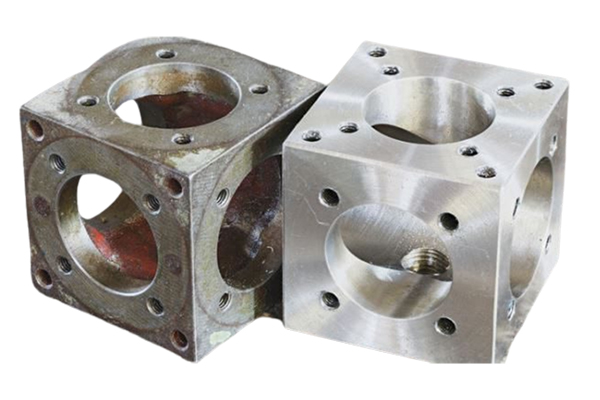

Drilling and Boring

Adds holes or enlarges existing ones with precision.

Grooving and Parting

Cuts grooves or separates finished parts from the stock.

Materials and Surface Finishes Supported by XTJ Machining

Varies by material type, generally high hardness. Tool selection and cutting parameters should be based on specific composition, with attention to wear resistance and thermal stability.

Aluminum (e.g., 6061, 7075)

Characteristics: Lightweight, good thermal conductivity, easy to machine, chips break easily. May cause tool sticking; requires proper cooling and lubrication. Suitable for high-speed milling.

Steel (e.g., stainless, carbon)

Characteristics: High hardness, wear-resistant, but generates high cutting forces and heat during machining. Requires low-speed milling with hard tools (e.g., carbide). Stainless steel may exhibit work hardening.

Titanium

Characteristics: High strength, low thermal conductivity, heat concentrates during machining, causing tool wear. Requires low-speed cutting, high-performance tools, and sufficient cooling.

Brass

Characteristics: Soft and easy to machine, good machinability, chips break easily, high surface finish. Suitable for high-speed milling, generates less heat.

Copper

Characteristics: High thermal conductivity, ductile, prone to tool sticking during machining. Requires sharp tools and proper lubrication. Chips may be long, so chip removal is important.

ABS

Characteristics: Good toughness, easy to machine, but prone to softening from heat. Requires controlled cutting speed and cooling to avoid melting or burrs.

POM (Polyoxymethylene)

Characteristics: Moderate hardness, wear-resistant, self-lubricating, stable during machining, good surface finish. Be cautious of thermal deformation.

PEEK

Characteristics: High temperature resistance, chemical resistance, high hardness. Requires hard tools, generates high cutting forces, and needs temperature control to prevent deformation.

Polycarbonate

Characteristics: Transparent, high toughness, but prone to stress cracking. Requires low-speed cutting to avoid overheating, and sharp tools are necessary.

Nylon

Characteristics: High toughness, wear-resistant, but hygroscopic and prone to deformation during machining. Requires controlled cutting speed, suitable for low-speed milling.

Carbon Fiber

Characteristics: High strength, lightweight, but very hard. Prone to delamination or burrs during machining. Requires diamond or carbide tools, and dust protection is necessary.

Fiberglass

Characteristics: High hardness, corrosion-resistant, but abrasive to tools and generates dust during machining. Requires efficient dust extraction and hard tools.

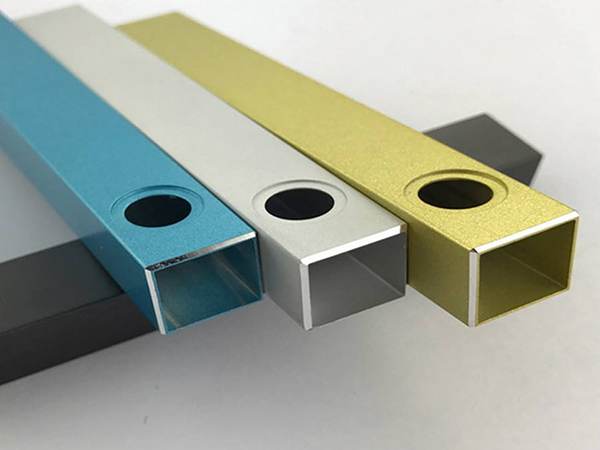

Elevate Your Parts with Advanced Surface Finishing

Enhance the durability, functionality, and aesthetics of your components with XTJ’s range of surface finishing options. Each process is tailored to meet specific performance and design requirements, ensuring your parts not only perform exceptionally but also look their best.

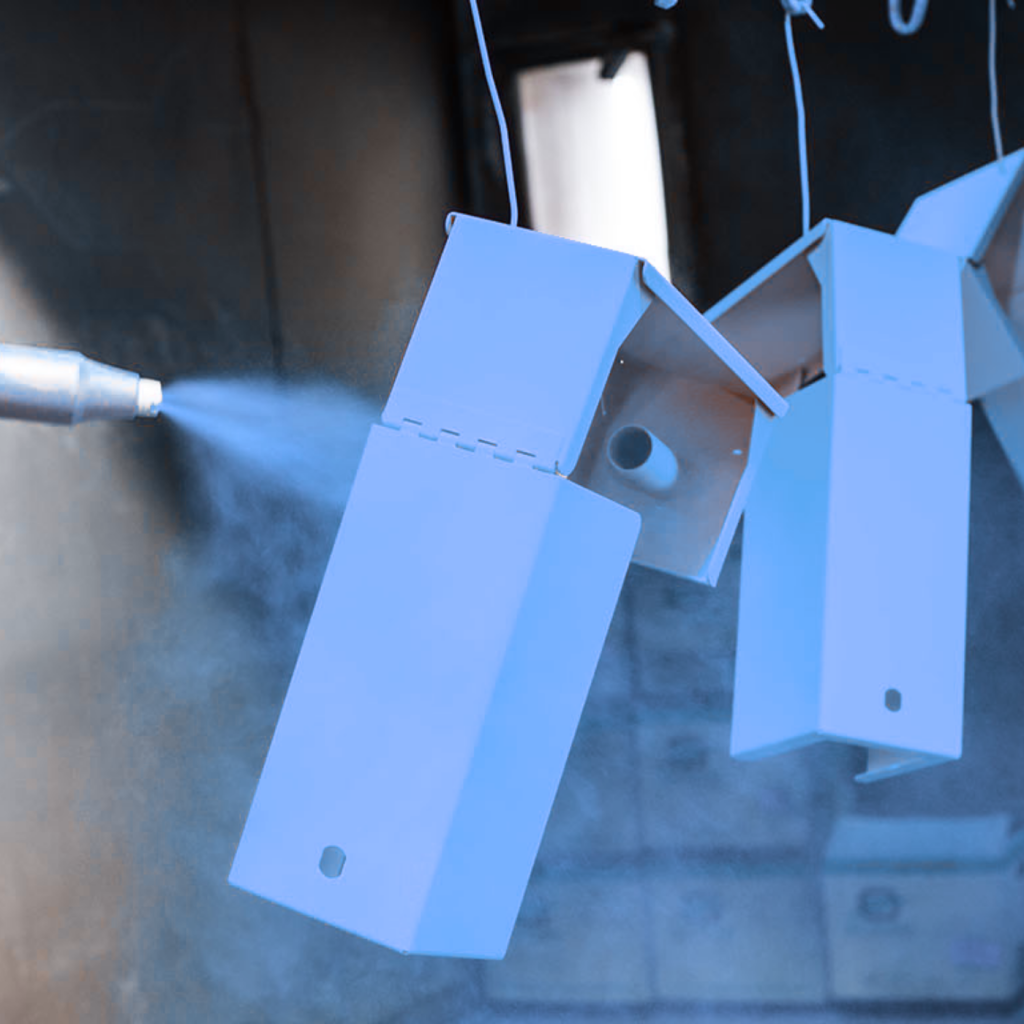

Durable and Versatile Coating for Long-Lasting Protection

Powder coating applies a dry powder—typically a mix of resin and pigment—electrostatically to the part, which is then cured under heat to form a tough, protective layer. This finish is known for its durability and resistance to chipping, scratching, and corrosion.

Durable and Versatile Coating for Long-Lasting Protection

Powder coating applies a dry powder—typically a mix of resin and pigment—electrostatically to the part, which is then cured under heat to form a tough, protective layer. This finish is known for its durability and resistance to chipping, scratching, and corrosion.

Uniform Matte Finish for Enhanced Aesthetics

Bead blasting uses small glass beads propelled at high pressure to create a consistent, non-reflective matte finish on the surface of parts. This process removes surface imperfections and provides a clean, uniform texture.

Mirror-Like Finish for Premium Applications

Polishing involves mechanically smoothing the surface of a part to achieve a high-gloss, mirror-like finish. This process enhances both the visual appeal and the tactile quality of the component.

Enhanced Corrosion Resistance for Stainless Steel

Passivation is a chemical treatment that removes free iron from the surface of stainless steel parts, forming a passive oxide layer that significantly improves corrosion resistance.

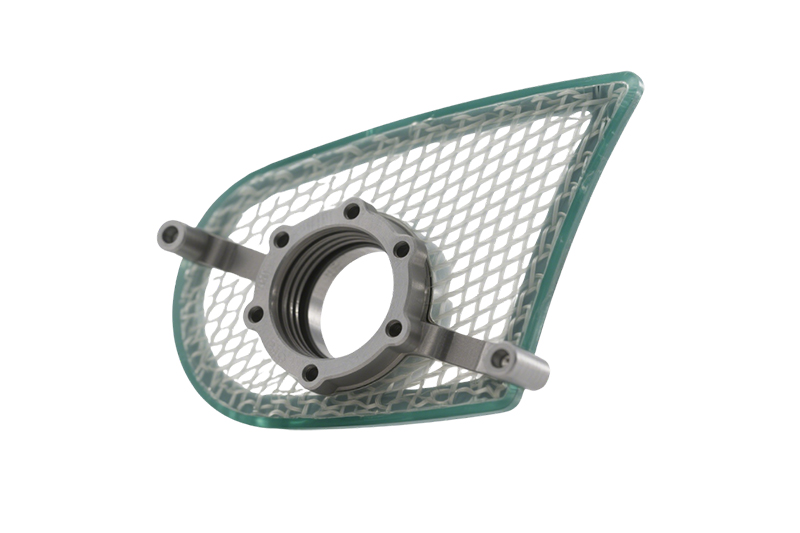

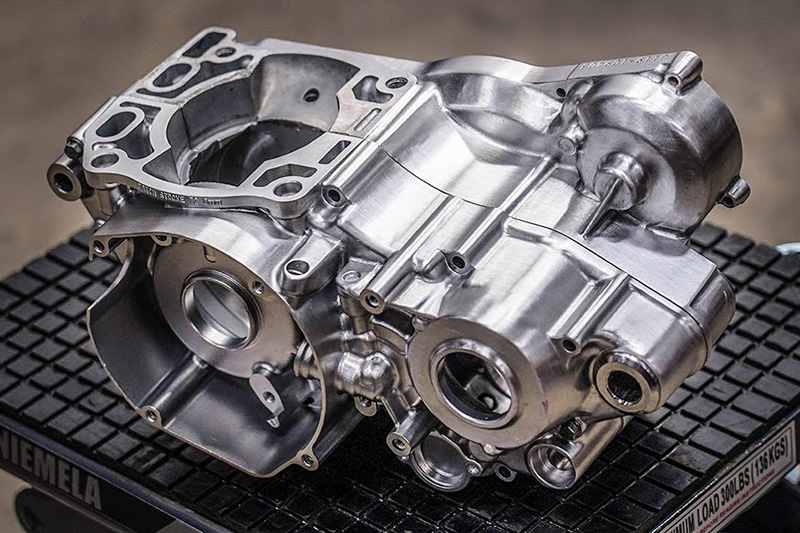

What is CNC Turning?

CNC turning is a subtractive process where a cutting tool moves along a rotating workpiece to create cylindrical parts. At XTJ, we utilize 2-axis, 3-axis, and multi-axis CNC turning to produce components with features like threads, grooves, and tapers, offering flexibility for simple to complex designs.

Serving Diverse Industries with CNC Turning Parts

Aerospace

Manufacture lightweight, high-strength parts like turbine blades and structural components that meet stringent aerospace standards.

Automotive

Produce engine components, transmission parts, and custom fittings with tight tolerances for high-performance vehicles.

Medical

Create precision instruments and implants with biocompatible materials like titanium and PEEK for medical applications.

Electronics

Fabricate small, intricate parts like enclosures and heat sinks for consumer electronics and telecommunications.

From Design to Delivery in 5 Simple Steps

Collaborate with us effortlessly: Submit your design, get expert feedback, approve your quote, and launch production. Stay informed at every stage for reliable, high-quality outcomes.

Looking for affordable, reliable CNC turning services?

Partner with XTJ Precision Mfg for precision, efficiency, and great value.