Precision Machining for Affordable Custom Heat Sinks

Precision Thermal Solutions for Optimal Performance

reduce costs by up to 35%, and accelerate project timelines.

- 91% Customer Retention (10 years)

- Global delivery, Real factory, welcome to visit

- Fast, flexible production of custom heat sinks for small to medium orders.

Why Choose Custom Heat Sinks?

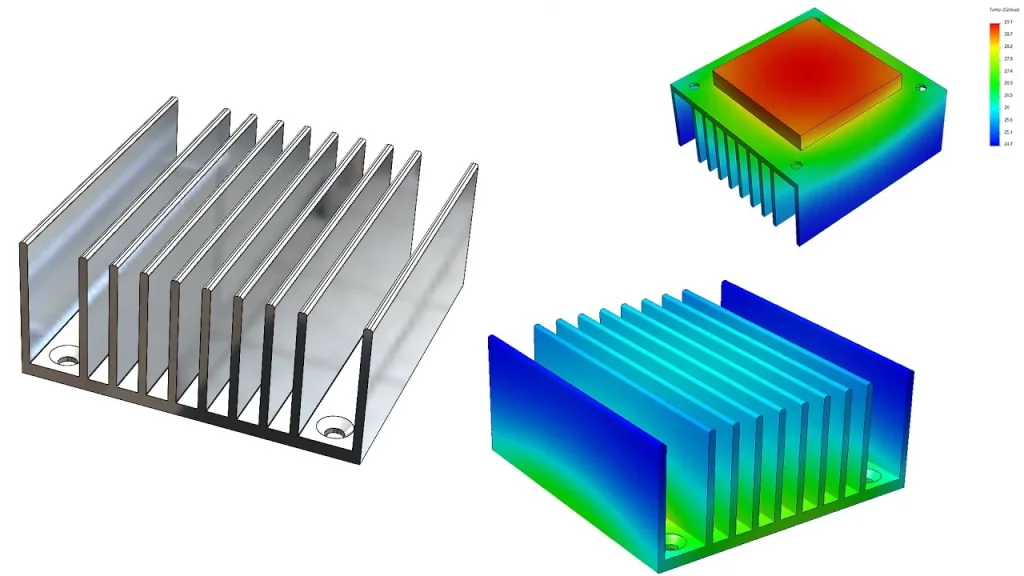

A heat sink is a passive cooling device that absorbs and dissipates heat from electronic or mechanical systems, preventing overheating and extending component life. Custom heat sinks offer tailored designs optimized for your specific thermal profile, outperforming standard solutions by improving efficiency, minimizing size and weight, and addressing unique environmental challenges.

Key Benefits of Customization:

Enhanced Thermal Performance: Achieve up to 25-35% lower operating temperatures with optimized fin geometry and material selection.

Compact Designs: Tailored shapes fit constrained spaces without sacrificing cooling capacity.

Cost Efficiency: Streamlined production reduces material waste and overall costs.

Application-Specific Solutions: Meet stringent requirements for industries like aerospace, automotive, and high-performance computing.

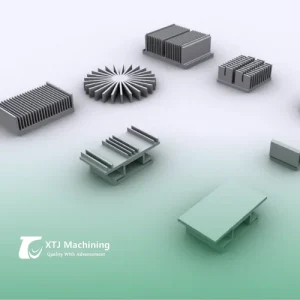

Our Custom Heat Sink Types

XTJ Precision Mfg offers a wide range of custom heat sink types, each crafted with precision to suit your application’s needs:

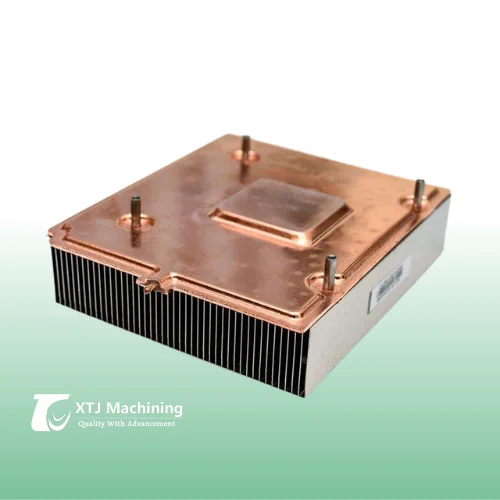

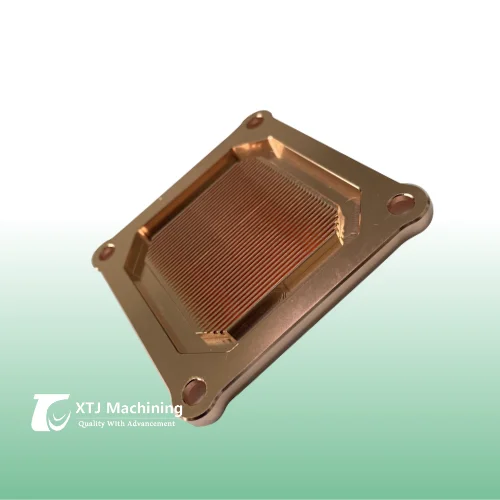

Custom Vapor Chamber Heat Sink

A planar heat pipe that spreads heat uniformly across its surface, creating an isothermal base. Perfect for applications with concentrated heat sources, such as high-performance computing or LED systems.

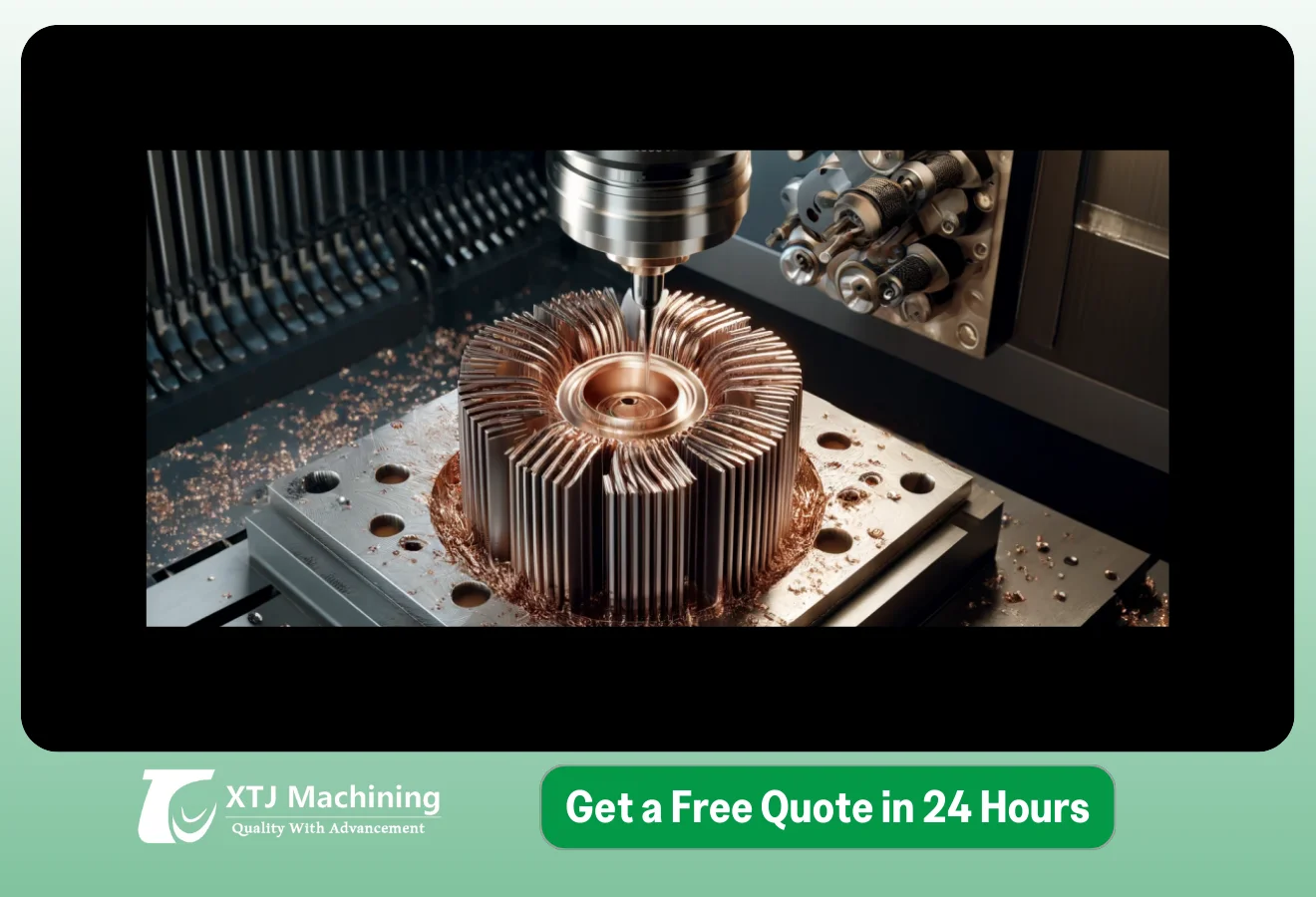

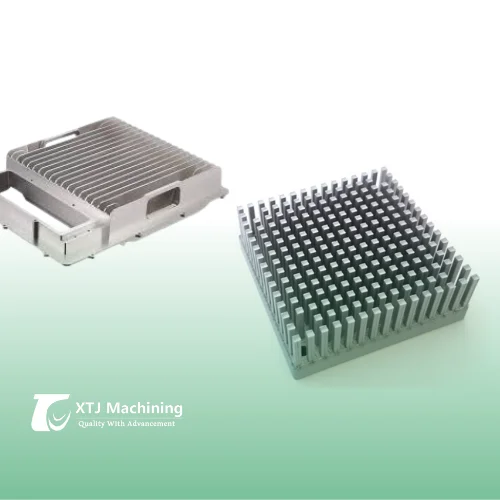

Machined Custom Heat Sink

Utilizing our advanced CNC machining capabilities, we produce heat sinks with complex features, contours, cut-outs, and through-holes. Low setup costs make this ideal for low to medium volumes, with tolerances as tight as ±0.005mm.

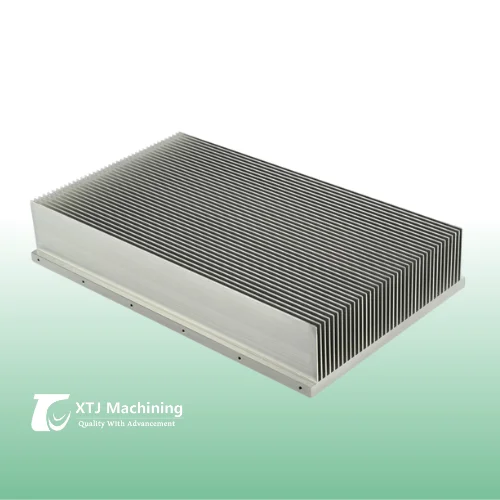

Custom Extruded Heat Sink

Aluminum extrusions provide a cost-effective solution for high-volume production. Uniform fin profiles ensure efficient airflow, suitable for electronics and automotive applications.

Custom Casted Heat Sink

Using investment casting, we create complex heat sink designs quickly and affordably. This process is perfect for prototypes and short to medium production runs, delivering intricate shapes with high precision.

Custom Die-Cast Heat Sink

Our proprietary high-thermal-conductivity aluminum alloy (~160 W/mK) enables cost-effective die-casting for medium to large production volumes. Ideal for rugged applications requiring consistent performance.

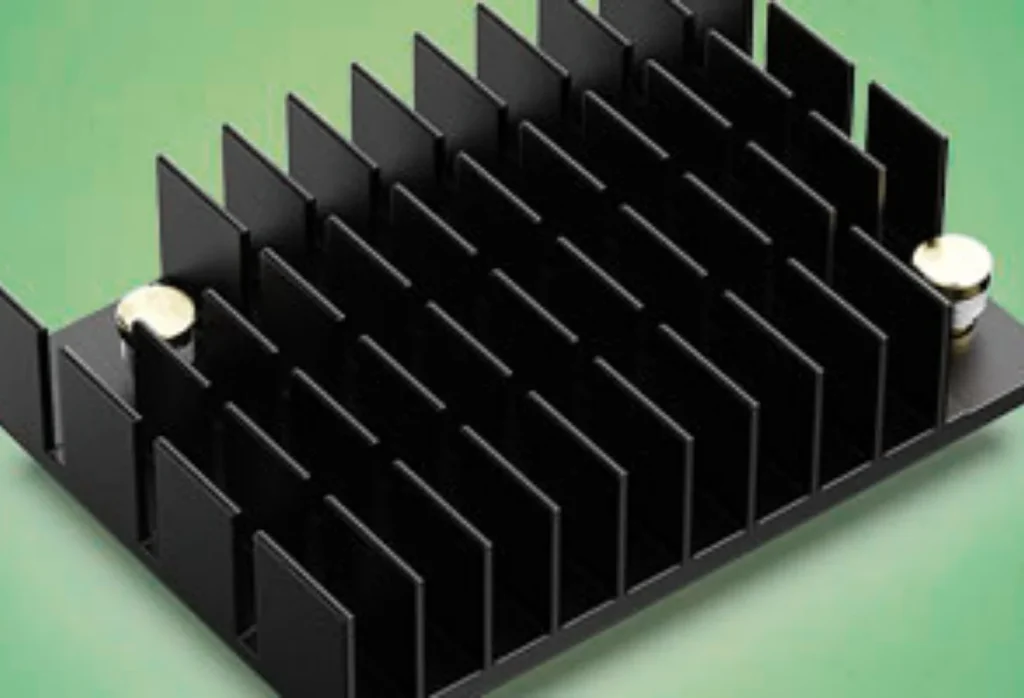

Custom Skived Heat Sink

A controlled shaving technique creates high-density, thin-fin heat sinks from a single block of aluminum or copper. This method ensures uniform fins and excellent thermal performance in compact spaces.

Custom Stamped Fin Heat Sink

Stamped from sheets of aluminum or copper, these heat sinks offer flexible fin geometries and thicknesses. Perfect for medium to high-volume production with customized designs for specific airflow needs.

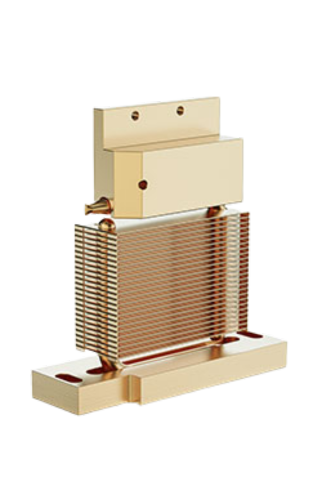

Custom Heat Pipe Heat Sink

A vacuum-sealed copper tube filled with a working fluid (e.g., water) rapidly transfers heat to cooler regions with minimal temperature rise. Ideal for high-heat-flux applications like CPUs, GPUs, and power electronics.

Complex 3D Geometries

Fully bespoke designs with integrated features like mounting holes or embedded heat pipes.

Best Material Options for Custom Heat Sinks

Lightweight (2.7 g/cm³), high thermal conductivity (205-250 W/mK), and cost-effective. Ideal for electronics, automotive, and consumer devices.

Exceptional conductivity (385-401 W/mK) for high-heat applications, such as data centers and industrial equipment.

Aluminum-silicon or copper-tungsten composites for enhanced strength, thermal expansion matching, or corrosion resistance.

Aluminum-silicon or copper-tungsten composites for enhanced strength, thermal expansion matching, or corrosion resistance.

Benefits of Partnering with XTJ Precision Mfg

All processes are ISO 9001:2015-certified, with rigorous quality control, including thermal testing and Computational Fluid Dynamics (CFD) simulations to validate performance.

Tailored Solutions

Work directly with our engineers to design heat sinks that meet your exact specifications.

Cost Efficiency

Streamlined processes and direct factory collaboration save up to 35% on production costs.

Rapid Turnaround

Prototypes in 1-2 weeks, full production in 2-4 weeks.

High Precision

Advanced machining ensures tolerances as tight as ±0.005mm.

Scalability

From one-off prototypes to high-volume production runs.

Sustainability

Eco-friendly materials and processes minimize waste.

Choose Our Custom Heatsinks

As a leading machining and fabrication provider, XTJ Precision Mfg offers end-to-end services, from design consultation to final production. Our expertise in custom manufacturing, combined with advanced tools like CFD analysis and thermal testing, ensures your heat sinks perform reliably in the most demanding conditions. By working directly with our factory, you benefit from competitive pricing, personalized service, and unmatched quality.

Get Started Today

Ready to solve your thermal challenges? Upload your design or specifications for a free quote within 48 hours. Our team will collaborate with you to select the best heat sink type, material, and manufacturing process for your needs.