CNC Machining for Home Appliance Manufacturers: Get The Best Quality and Precision

CNC machining is a popular manufacturing process in the electronics industry. This process uses computer-controlled tools to create parts with high precision. Many companies use CNC machining to develop electronic components, such as printed circuit boards and sensors. If you’re looking for the best CNC machining services for your electronic parts, read on.

About the Home Appliance Manufacturing Industry

The home appliance manufacturing industry is a large and complex one, with many different types of appliances being produced. There are a few key players in the industry, with most appliances being produced by just a handful of companies. The industry is highly competitive, with companies constantly innovating and trying to one-up each other in terms of features and design.

There are a number of issues that face the home appliance production industry. One of the biggest issues is the high cost of labor. This is due to the fact that most home appliances are produced in developed countries where labor costs are high. Additionally, the cost of raw materials has been rising in recent years, which has also put pressure on the industry. In order to compete, many manufacturers have outsourced production to low-cost countries. This, in its turn, has led to quality issues and has resulted in consumers being confused about which products are actually the best.

The home appliance manufacturing industry is a large and complex one, with many different types of appliances being produced. There are a few key players in the industry, with most appliances being produced by just a handful of companies. The industry is highly competitive, with companies constantly innovating and trying to one-up each other in terms of features and design.

There are a number of issues that face the home appliance production industry. One of the biggest issues is the high cost of labor. This is due to the fact that most home appliances are produced in developed countries where labor costs are high. Additionally, the cost of raw materials has been rising in recent years, which has also put pressure on the industry. In order to compete, many manufacturers have outsourced production to low-cost countries. This, in its turn, has led to quality issues and has resulted in consumers being confused about which products are actually the best.

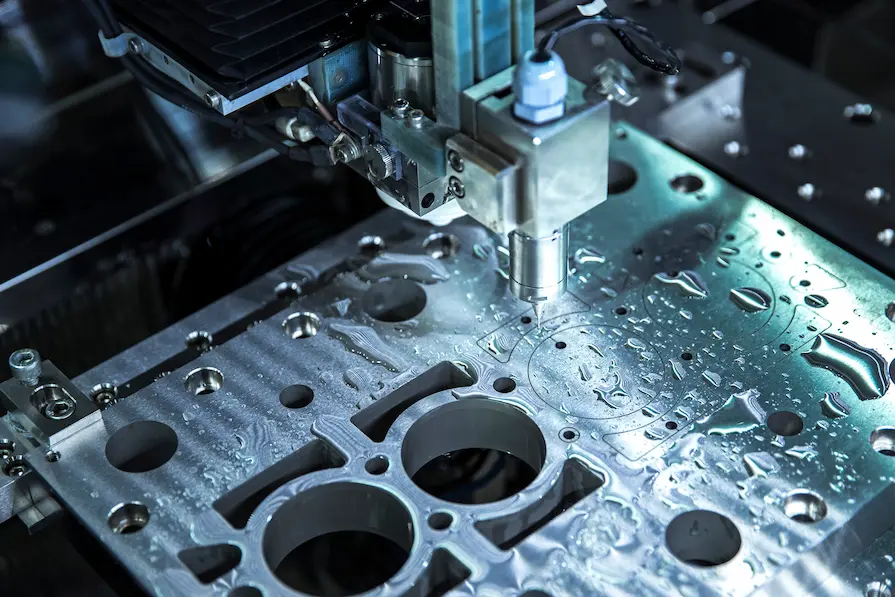

Introducing CNC machining may be the awaited solution to a major part of these issues. It is a process that uses computer-controlled machines to create parts from a variety of materials. This technology is often used in the home appliance production industry because it can help to reduce labor costs. CNC machining can automate many of the tasks that would otherwise need to be performed by human workers, and it can also produce parts with a high degree of accuracy and repeatability.

Some examples of appliances that use CNC machining in their manufacturing process include washing machines, dryers, dishwashers, and refrigerators. CNC machining allows for precise and accurate cuts to be made in metal, plastic, and other materials used in appliance manufacturing. This results in a higher quality product that is more durable and longer-lasting.

The Quality and Precision of CNC Machined Home Appliances

CNC machined home appliances are known for their quality and precision. When it comes to home appliances, these two factors are of the utmost importance. After all, you want your appliances to last for years and to work correctly every time you use them. With CNC machining, you can rest assured that your appliances will be built to last.

Some other benefits of CNC machined appliances than increased accuracy include repeatability and efficiency. With repeatability, parts and components can be produced consistently with little to no variation. This ensures a product is the same every time it comes off the line. Efficiency is increased because CNC machines are faster and produce more consistent results than hand-operated machines.

CNC machined home appliances are known for their quality and precision. When it comes to home appliances, these two factors are of the utmost importance. After all, you want your appliances to last for years and to work correctly every time you use them. With CNC machining, you can rest assured that your appliances will be built to last.

Some other benefits of CNC machined appliances than increased accuracy include repeatability and efficiency. With repeatability, parts and components can be produced consistently with little to no variation. This ensures a product is the same every time it comes off the line. Efficiency is increased because CNC machines are faster and produce more consistent results than hand-operated machines.

CNC machined appliances also have increased strength and durability. The components they create are made from high-quality materials that can withstand high levels of stress and wear and tear. They are also designed to be resistant to damage from water, heat, and chemicals.

CNC machines can also be used to create complex shapes and designs that would be difficult or impossible to create with traditional methods. In addition, CNC machines can be programmed to produce multiple parts quickly and with little to no human intervention, which can save time and labor costs.

If you’re looking for high-quality CNC machining services, look no further than our team at XTJ machining. We’ll work with you to create the perfect solution for your needs, and we’re always available to answer any questions you may have. Contact us today to get started!

Our Appliance Production Services

Xin Tian Jian is experienced in manufacturing precision components for home appliances. If you need a part to keep production of your large-scale home appliances manufacturing running smoothly, XTJ has what you need.

We offer a plethora of services:

- CNC Machining

- Rapid Prototyping

- Sheet Metal Fabrication

- Vacuum Casting

- 3D Printing

- Surface Finishing

- RIM

- Injection Molding

- Plastic Injection Molding

- Aluminum Extrusion Services

Irreproachable Quality

Xin Tian Jian Machining is a professional CNC machining service provider, ISO9001 and ISO14001 certified, with over 16 years of experience and an excellent reputation in the industry. We hold ourselves accountable for not only guaranteeing the highest quality of our work but also for continuous improvement. That is why every project is backed by strict quality control standards and good manufacturing practices.

Cost-effectiveness & Quick Delivery

We provide an affordable machining service that saves your investment from costly mistakes that you might otherwise make during the process of design, sourcing or construction of your project. We use cutting-edge technology to bring your project to life. We offer the most competitive rates and turn-around time. We have the capacity to handle everything from small-scale to large-scale project that is looking for machining services worldwide.

Start Your Project With A Free Quote

If you’re looking for a reliable partner to help you get your aerospace machining project off the ground, look no further than us. We have a long history of providing precision machining services to clients in a wide range of industries. Let us put our experience to work for you and start your project off on the right foot.