Introduction: The Critical Role of Material Selection in Metal Parts Machining

Machining metal parts is a cornerstone of modern manufacturing, enabling precision components for industries like aerospace, automotive, and electronics. The choice of metal material profoundly influences machining efficiency, tool life, part performance, and production costs. Metals exhibit unique properties—malleability, ductility, conductivity, and density—that determine their machinability and suitability for specific applications. For example, aluminum’s lightweight and corrosion-resistant nature supports high-speed machining, while titanium’s strength is ideal for critical parts but demands specialized techniques. At XTJ Precision Mfg, a leading Chinese manufacturer, we combine material expertise with advanced CNC technology to deliver high-quality, cost-effective metal parts that meet global industry standards. This article explores metal types, their properties, and how strategic material selection optimizes machining metal parts.

Common Metal Materials and Their Machining Characteristics

The success of machining metal parts depends on understanding how a material’s properties—such as density, strength, and conductivity—affect its behavior during cutting, milling, or turning. Below, we explore the most commonly used metals in manufacturing, detailing their characteristics and machining considerations to guide effective material selection.

Aluminum Alloys

Aluminum alloys, such as 6061 and 7075, are widely chosen for their low density (2.7 g/cm³) and excellent corrosion resistance, making them ideal for lightweight components like automotive hoods or aerospace airframes. Their high electrical conductivity (3.77 × 10⁷ S/m) and malleability allow forming into complex shapes, such as thin sheets or intricate brackets. In CNC machining, aluminum’s high machinability enables rapid cutting speeds (800-1000 m/min) and short cycle times, boosting production efficiency. However, its softness can lead to material adhesion on tools, requiring lubricants to achieve smooth surface finishes (Ra 0.8 µm). Aluminum is prevalent in automotive, aerospace, and electronics industries, where weight reduction and durability are critical.

Stainless Steel

Stainless steel, including grades like 304 and 316, excels in applications requiring corrosion resistance, such as medical instruments and marine fittings. With a density of 7.9 g/cm³ and moderate ductility, it offers robust mechanical strength (500-700 MPa). Machining stainless steel presents challenges due to its tendency to work-harden, which accelerates tool wear and generates significant heat. Low cutting speeds (50-100 m/min) and durable carbide tools are essential to maintain precision (±0.01 mm) and manage temperatures. Effective cooling, such as flood coolant, ensures dimensional accuracy and extends tool life, making stainless steel a reliable choice for durable, high-performance parts.

Carbon Steel

Carbon steel (e.g., 1018, 1045) is a cost-effective option for structural components like machinery frames and construction beams, offering high strength (600 MPa) at a density of 7.8 g/cm³. Its moderate ductility supports forming, but its susceptibility to rust requires protective coatings in some applications. During machining, carbon steel cuts efficiently at moderate speeds (100-200 m/min), making it suitable for high-volume production. However, thermal deformation can occur, necessitating cooling systems to maintain tolerances. Its affordability and versatility make it a staple in manufacturing general-purpose parts.

Titanium Alloys

Titanium alloys, such as Ti-6Al-4V, are prized for their high strength-to-weight ratio (900 MPa at 4.5 g/cm³) and heat resistance (melting point 1668°C), ideal for aerospace turbine blades and medical implants. Their low thermal conductivity (6.7 W/m·K) traps heat at the cutting edge, elevating tool temperatures to 800°C and causing rapid wear. Machining requires slow speeds (30-60 m/min), high-pressure coolant (70 bar), and specialized polycrystalline diamond (PCD) tools to achieve tight tolerances (±0.005 mm). Despite higher costs, titanium’s durability and biocompatibility justify its use in critical applications.

Copper and Copper Alloys

Copper’s exceptional electrical conductivity (5.96 × 10⁷ S/m) makes it the material of choice for electrical connectors and heat exchangers. With a density of 8.9 g/cm³, its high malleability and ductility enable forming into wires or forged components. Machining copper is straightforward but requires attention to its softness (hardness 50 HB), which can cause material sticking and burr formation. Moderate cutting speeds (80-150 m/min) and sharp high-speed steel (HSS) tools ensure clean cuts and high precision (±0.002 mm), critical for electronics where surface quality impacts performance.

Magnesium

Magnesium, with a density of 1.74 g/cm³, is the lightest structural metal, commonly alloyed for enhanced strength in automotive wheel rims and aerospace casings. Its high machinability supports fast cutting, but fine chips pose a fire risk, requiring dry machining or minimal coolant to prevent ignition. Magnesium’s low density and formability make it a go-to for weight-sensitive applications, though careful process control is needed to ensure safety and quality.

Brass

Brass, a copper-zinc alloy (前的消息: (density 8.5 g/cm³), combines corrosion resistance with excellent machinability, making it ideal for valves, locks, and decorative fittings. Its moderate strength and ability to produce clean cuts at high speeds (200-300 m/min) reduce tool wear and machining time. Brass’s aesthetic appeal and ease of machining make it a cost-effective choice for both functional and ornamental parts.

Zinc

Zinc (density 7.1 g/cm³) is valued for its corrosion resistance, often used in coatings, die casting, and electrical hardware. Its softness enables efficient machining, but like copper, it can adhere to tools, requiring optimized parameters and light lubrication to achieve smooth finishes. Zinc’s role in producing durable, lightweight components is growing, particularly in pipelines and electronics manufacturing.

Key Factors in Material Selection for Machining Metal Parts

Selecting the optimal metal for machining requires a detailed analysis of technical, economic, and regulatory factors to balance performance, cost, and feasibility.

Part Functionality and Performance Requirements:

-

- Mechanical Properties: Strength, hardness, and ductility dictate suitability. Titanium’s tensile strength (900 MPa) suits load-bearing aerospace parts, while aluminum’s ductility (elongation 15%) enables complex geometries.

- Environmental Resistance: Stainless steel 316 (Cr 16-18%) resists corrosion in marine environments, while titanium’s biocompatibility (ISO 10993) is critical for medical implants.

- Thermal and Electrical Properties: Copper’s high conductivity (5.96 × 10⁷ S/m) is ideal for electrical connectors, while titanium’s heat resistance (melting point 1668°C) suits high-temperature applications.

- Example: For an automotive bracket, aluminum 6061 (strength 310 MPa) balances weight and cost, while carbon steel (600 MPa) is chosen for high-load chassis parts.

Machining Equipment and Tool Compatibility:

- Equipment capabilities limit material options. High-speed CNC machines (20,000 RPM) excel with aluminum, while titanium requires rigid, high-torque machines (500 Nm).

- Tool selection impacts efficiency. Carbide tools handle stainless steel’s hardness (200-300 HB), but titanium demands PCD tools to reduce wear (tool life 100-200 parts vs. 50 for carbide).

- Example: Milling titanium at 40 m/min with PCD tools reduces tool temperature from 800°C to 500°C, extending life by 40%.

Cost Optimization Models:

- Material Costs: Aluminum ($2-3/kg) is more affordable than titanium ($20-30/kg), influencing budget decisions.

- Machining Time: Aluminum’s machinability reduces cycle times (8 min/part vs. 25 min for titanium), lowering labor costs.

- Tool Wear: Titanium’s abrasiveness increases tool replacement costs ($50/tool every 100 parts vs. $10/tool for aluminum).

- Example: Optimizing stainless steel machining with lower feed rates (0.1 mm/rev) reduced cycle time by 25% and tool costs by 15%, saving $10,000 over 5000 parts.

Industry Standards and Regulatory Compliance:

- Aerospace parts require AMS or ASTM standards (e.g., AMS4911 for titanium). Medical devices demand biocompatibility (ISO 10993).

- Environmental regulations restrict lead use or coolant disposal, affecting material and process choices. For example, magnesium machining avoids water-based coolants to prevent ignition.

- Example: Compliance with AS9100 ensures aerospace parts meet fatigue resistance standards, critical for titanium components.

- Simulation and Testing: Finite element analysis (FEA) predicts material behavior under machining stresses, while trial runs validate parameters. For instance, FEA confirmed aluminum 7075’s suitability for a lightweight aerospace bracket, reducing weight by 20%.

Strategies to Optimize Machining Performance

Optimizing the machining of metal parts requires tailoring strategies to each material’s properties—such as malleability, thermal conductivity, and hardness—to maximize efficiency, precision, and cost-effectiveness. Below are detailed approaches, supported by specific parameters and examples, to achieve high-quality results across metals like aluminum, stainless steel, titanium, and copper.

- Cutting Parameters

Adjusting spindle speed, feed rate, and depth of cut to match a metal’s properties is critical for efficiency and quality. For aluminum (e.g., 6061), high spindle speeds of 15,000-20,000 RPM and feed rates of 0.2-0.3 mm/rev enable rapid milling (800-1000 m/min), reducing cycle times by up to 30% (e.g., 8 min/part for an automotive bracket). Stainless steel (e.g., 304) requires lower speeds (5000-8000 RPM, 50-100 m/min) and conservative feed rates (0.1 mm/rev) to mitigate work hardening, which can increase tool wear by 20%. Titanium’s low thermal conductivity (6.7 W/m·K) demands slow speeds (3000-5000 RPM, 30-60 m/min) and shallow cuts (0.05-0.1 mm depth) to manage heat, as demonstrated in machining aerospace turbine blades, where optimized parameters improved tolerances to ±0.005 mm. Copper’s softness allows moderate speeds (80-150 m/min, 0.15 mm/rev), ensuring burr-free cuts for electronics connectors. - Tool Selection

Choosing the right tool material and geometry enhances performance and longevity. For stainless steel, carbide tools with TiN or AlTiN coatings handle hardness (200-300 HB), extending tool life to 150 parts per tool in milling marine fittings. Titanium requires polycrystalline diamond (PCD) tools (e.g., Sandvik Coromant PCD10), which withstand high temperatures (500°C vs. 800°C with carbide), increasing tool life by 40% (200 parts/tool) in aerospace applications. Copper and brass benefit from sharp high-speed steel (HSS) tools (e.g., OSG HYPRO-CARB), which prevent material adhesion and achieve ±0.002 mm precision in micro-scale electronics parts. For magnesium, uncoated carbide tools support high-speed cutting (200-300 m/min) while minimizing chip ignition risks.

- Cooling and Lubrication

Effective thermal management prevents deformation and extends tool life. Titanium machining uses high-pressure flood coolant (70 bar, 10 L/min) to reduce tool temperatures from 800°C to 500°C, as seen in turbine blade production, improving surface finish to Ra 0.8 µm. Aluminum requires minimal lubrication (e.g., mist coolant at 0.5 L/min) to clear chips and prevent sticking, boosting efficiency in automotive part production. Stainless steel benefits from flood cooling (5 L/min) to control heat during low-speed milling (50 m/min), maintaining dimensional accuracy. Magnesium machining often employs dry conditions or minimal mist coolant (0.2 L/min) to avoid ignition risks, ensuring safety in aerospace casing production. - Process Planning

Optimizing CNC tool paths and programming reduces machining time and waste. For aluminum 6061, 3D tool path optimization (e.g., Mastercam Dynamic Motion) minimizes tool movements, cutting cycle time by 20% (from 10 to 8 min/part) in automotive brackets. For titanium, adaptive milling strategies adjust feed rates dynamically (0.05-0.1 mm/rev), reducing vibrations and achieving ±0.005 mm tolerances in aerospace components. Copper’s micro-milling for 5G connectors uses high-precision paths to ensure 95% yield rates. Simulation software (e.g., Siemens NX) predicts chip formation and heat distribution, optimizing parameters for high-density metals like stainless steel (7.9 g/cm³), saving 15% in production costs.

Case Studies: Material Choice in Action

Case 1: Automotive Engine Brackets (Aluminum vs. Carbon Steel)

- Context: A client required 10,000 engine brackets for a mid-size SUV, prioritizing weight reduction and cost.

- Challenge: Aluminum 6061 (density 2.7 g/cm³, strength 310 MPa) offered weight savings but lower strength than carbon steel 1045 (7.8 g/cm³, 600 MPa).

- Solution: Finite element analysis (FEA) confirmed aluminum’s suitability for non-critical loads. Machining used high-speed CNC (800 m/min, 0.2 mm/rev feed), with flood lubrication to prevent tool sticking. Carbon steel was tested at 150 m/min, requiring heavier cooling to avoid thermal deformation.

- Outcome: Aluminum brackets reduced vehicle weight by 15 kg, saving $50,000 in production costs (8 min/part vs. 12 min for steel). Carbon steel was used for high-load chassis parts, balancing durability and cost.

- Insight: Material choice hinges on application—aluminum for lightweight efficiency, steel for structural strength.

- Conduct Trials: Test small batches to confirm machining parameters, especially for ductile or brittle metals.

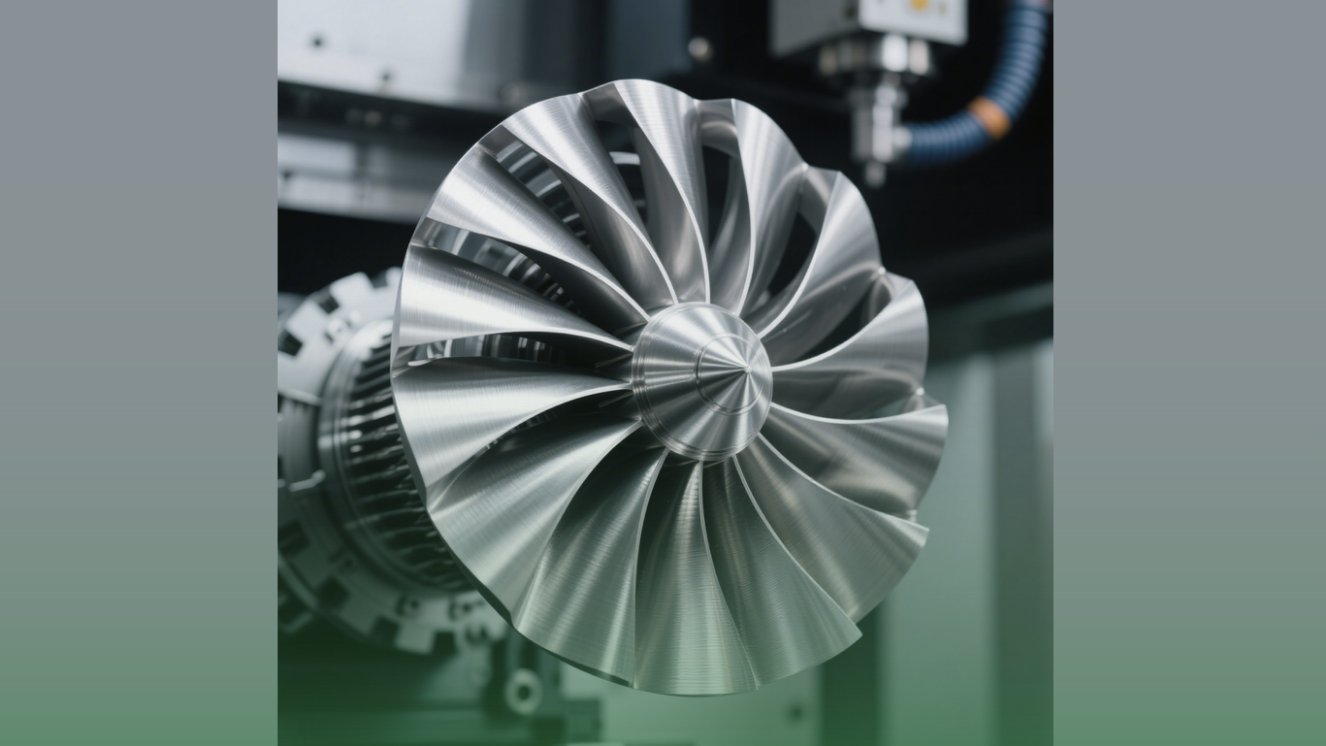

Case 2: Aerospace Titanium Turbine Blades

- Context: An aerospace client needed 500 turbine blades for a jet engine, requiring high strength and heat resistance.

- Challenge: Titanium Ti-6Al-4V’s low thermal conductivity (6.7 W/m·K) caused tool temperatures to reach 800°C, wearing out carbide tools in 50 parts.

- Solution: PCD tools ($200/unit) and high-pressure coolant (70 bar) reduced tool temperature to 500°C. Cutting speed was set at 40 m/min with 0.1 mm/rev feed. Tool path optimization minimized vibrations, achieving ±0.005 mm tolerances.

- Outcome: Tool life increased by 40% (200 parts/tool), and surface roughness improved to Ra 0.8 µm, meeting AMS4911 standards. Production costs dropped by 18% ($120/part).

- Insight: Titanium’s toughness demands specialized tools and cooling, but yields high-performance parts.

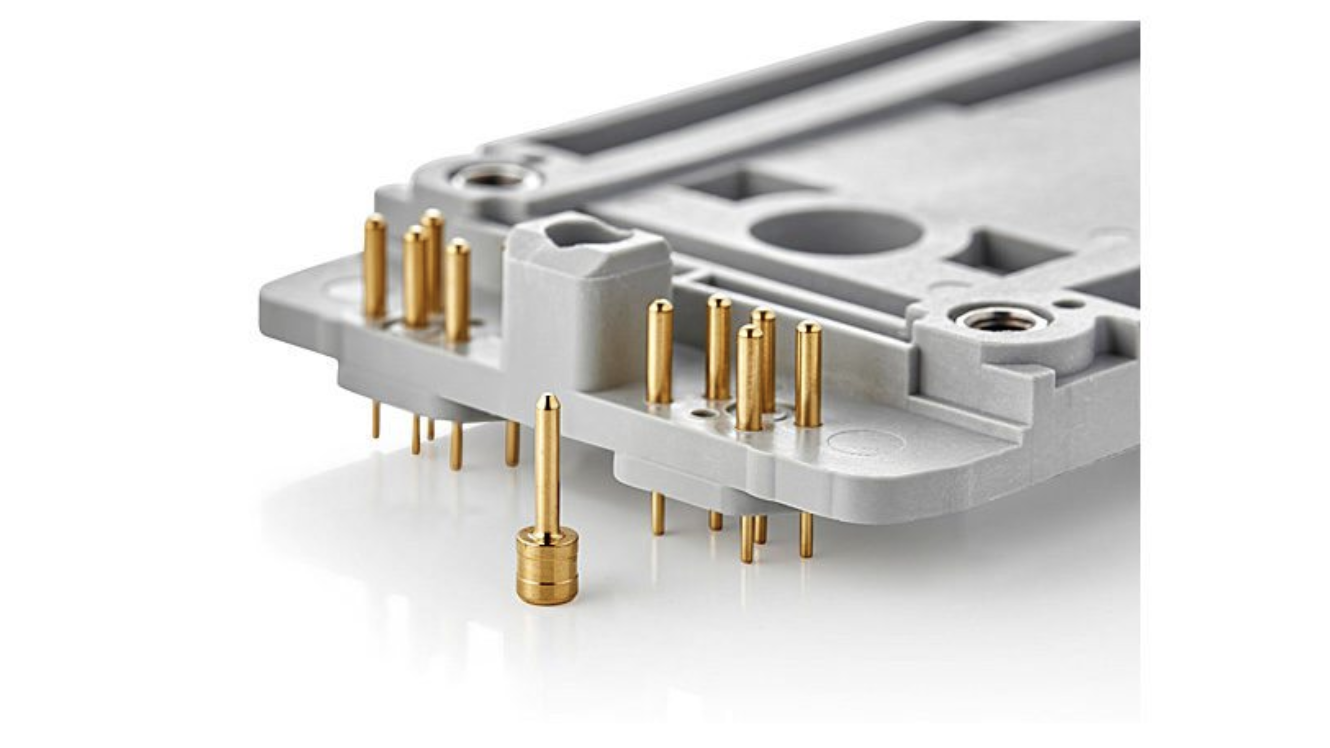

Case 3: Electronics Copper Connectors

- Context: An electronics manufacturer required 50,000 micro-scale connectors for 5G devices, needing high conductivity and precision.

- Challenge: Copper’s softness (hardness 50 HB) caused burrs during high-speed milling, risking electrical performance.

- Solution: Ultra-sharp HSS tools and moderate speeds (100 m/min, 0.15 mm/rev feed) were used. Micro-milling with 0.1 mm tools achieved ±0.002 mm tolerances. Minimal lubrication prevented surface contamination.

- Outcome: Burr-free connectors achieved 99.9% conductivity (5.96 × 10⁷ S/m), with a 95% yield rate. Production time was reduced by 30% (4 min/part).

- Insight: Copper’s conductivity and softness require precision tools to ensure micro-scale accuracy.

Conclusion and Practical Tips

Machining metal parts demands strategic material selection, leveraging properties like malleability, conductivity, and strength to optimize performance and cost. Aluminum enables rapid, cost-effective production, while titanium and stainless steel deliver durability for critical applications. As a top-tier Chinese manufacturer, XTJ Precision Mfg excels in combining material expertise with advanced CNC machining strategies—such as optimized cutting parameters, specialized tools, and high-pressure cooling—to produce high-quality, cost-effective metal parts. With tolerances as tight as ±0.002 mm and cost reductions up to 25%, XTJ meets stringent standards like AS9100 for aerospace and ISO 13485 for medical devices, serving global clients in automotive, aerospace, and electronics.

Partner with XTJ Precision Mfg to transform your designs into precision metal parts that exceed industry expectations.