Explore the top materials used in robot part machining, including metals, plastics, and composites for strength, precision, and cost-efficiency. This guide draws on industry standards and data to provide a comprehensive overview, supported by references from ASTM and ISO specifications, as well as practical insights from machining experiences.

Key Factors Influencing Material Selection for Robotic Components

Choosing the right material for robotic parts is more than just picking what’s available. It requires balancing several important factors to ensure the final product performs well and lasts long. Below, we incorporate quantitative data and standards to enhance clarity and reliability.

Balancing Strength, Weight, and Precision

- Strength: Robotic components need to handle stress and mechanical loads without failure. Materials should exhibit tensile strengths suitable for the application; for instance, aluminum alloys like 6061-T6 offer a tensile strength of 310 MPa and yield strength of 276 MPa, preventing breakdowns during operation.

- Weight: Lightweight materials improve robot speed and efficiency, reducing energy consumption and wear on motors. Titanium alloys, with densities around 4.5 g/cm³ and tensile strengths up to 1100 MPa in alpha-beta grades, provide an excellent strength-to-weight ratio.

- Precision: Some robotics parts demand tight tolerances (e.g., ±0.01 mm). Materials that machine smoothly and maintain exact dimensions, such as those with low thermal expansion coefficients (e.g., aluminum’s 23.6 × 10⁻⁶/K), help achieve this level of precision.

Finding the right balance is key. For example, aluminum alloys are strong and lightweight with good machinability, making them ideal for robotic arms that require quick movement and precision, as per ASTM B308 standards for structural profiles.

Environmental and Application Considerations

- Corrosion Resistance: Robots operate in diverse environments, from factories to outdoors. Materials like stainless steel 316, with added molybdenum, resist pitting and crevice corrosion in chloride-heavy settings, rated under ISO 16143-1 for corrosion-resistant stainless steels.

- Temperature Tolerance: Some applications involve heat, so materials must hold up under high temperatures without warping or losing strength. Ceramics, for instance, maintain stability up to 1000°C.

- Wear and Impact: Components exposed to friction or impact need tough, durable materials to extend robot life, such as tool steels with hardness ratings of 50-60 HRC.

Knowing where and how the robot will be used directly shapes the material choice to ensure reliability and safety.

Cost and Scalability in Machining

- Material Cost: Budget often plays a role, especially for mass production. Cheaper materials like ABS plastics (around $2-3/kg) can reduce expenses but must still meet functional requirements.

- Machinability: Materials that machine easily save time and reduce tooling wear, lowering manufacturing costs. For aluminum, recommended cutting speeds range from 600-1000 feet per minute (FPM) to optimize efficiency.

- Scalability: Some materials handle scaling better. For high-volume production, consistent material quality and availability become crucial, as seen in ISO-compliant stainless steels.

Balancing cost with performance and manufacturing ease helps create competitive robotic products that meet market demands.

Selecting materials for machining robot parts is a careful process of weighing strength, weight, precision, environment, cost, and scalability. Making the right choices upfront sets the stage for building reliable, efficient, and cost-effective robotic components.

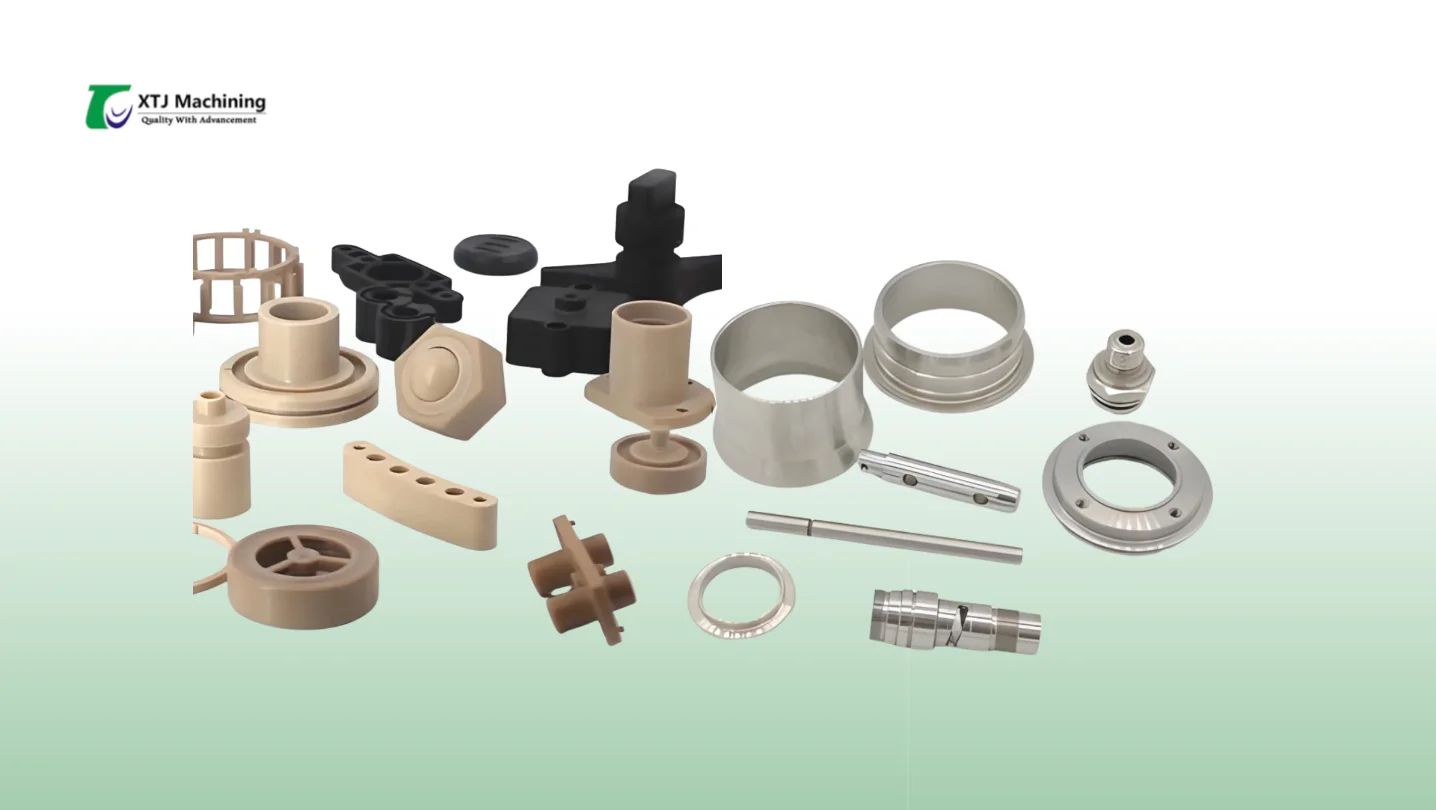

Essential Materials for Machining Robot Parts: In-Depth Breakdown

When it comes to CNC machining robotics components, choosing the right materials is crucial. Here’s a straightforward look at the key materials used in robot part machining and why they matter, complete with mechanical properties, standards, and a comparison table for better decision-making.

Metals: The Backbone of Durable Robotics

Metals provide the strength and durability needed for long-lasting robotic parts.

- Aluminum Alloys (6061-T6 and 7075-T6): These are top picks for robotic arms and frames because they offer a great balance of strength (tensile: 310 MPa for 6061-T6) and lightweight properties (density: 2.7 g/cm³). They’re easy to machine and perfect for parts needing precision tolerances in robot manufacturing, compliant with ASTM B308.

- Stainless Steel (304 and 316): Known for their corrosion-resistant qualities (316 offers superior resistance due to 2% molybdenum), these are common in robot gears and cobot components exposed to harsh environments. Tensile strengths range from 520-750 MPa for 304 and 500-680 MPa for 316, per ISO 16143-1.

- Steel Alloys (Including Carbon Steel and Tool Steel): Carbon steel is used for robust applications due to its strength (tensile up to 600 MPa) and wear resistance. Tool steel stands out when parts need to withstand heavy loads or cutting forces, with hardness up to 60 HRC.

- Titanium and Copper Alloys: Titanium is lightweight (density: 4.5 g/cm³) and super strong (tensile: 895-1100 MPa for alpha-beta alloys), ideal for aerospace and high-performance robots. Copper alloys, while less common, are important where electrical conductivity (up to 100% IACS) is required.

Plastics and Polymers: For Lightweight and Flexible Applications

Plastics are essential when weight savings and flexibility come into play.

- ABS and Nylon: Widely used for prototypes and non-structural parts, ABS is affordable and easy to machine with low friction. Nylon offers good strength (tensile: 50-80 MPa) and durability, often found in gears and bushings.

- Acetal (POM) and Polycarbonate: Acetal boasts low friction (coefficient: 0.2-0.3) and great machinability, making it ideal for moving parts. Polycarbonate is tough and impact-resistant (Izod impact: 12-16 kJ/m²), perfect for protective covers and transparent components.

- Elastomers like Silicone Rubber: Elastomers provide flexibility and vibration damping (Shore hardness: 30-80A), useful in sealing or cushioning robot parts.

Advanced Composites and Emerging Options

For cutting-edge robotics, advanced materials make a difference.

- Carbon Fiber Reinforced Polymers (CFRP): CFRP is key for lightweight, high-strength applications like drone parts and industrial robot arms, where reducing weight without sacrificing strength is critical. Typical tensile strength: 1500-3000 MPa, with low density (1.5-2.0 g/cm³).

- Ceramics and Bioplastics: Ceramics offer wear resistance (hardness: 1000-2000 HV) and thermal stability, useful in specialized environments. Bioplastics introduce sustainability options for less demanding parts, with properties similar to traditional plastics but biodegradable.

Material Comparison Matrix

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance (Rating: 1-5) | Machinability (Rating: 1-5) | Key Standard/Reference |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | 3 | 5 | ASTM B308 |

| Stainless Steel 304 | 520-750 | 8.0 | 4 | 3 | ISO 16143-1 |

| Titanium Alloy | 895-1100 | 4.5 | 5 | 2 | Biomedical standards |

| CFRP | 1500-3000 | 1.5-2.0 | 4 | 3 | N/A |

| Nylon | 50-80 | 1.1-1.4 | 2 | 4 | N/A |

Understanding these essential materials helps you match the right components to your robot’s specific needs — from strength and precision to flexibility and environmental resistance.

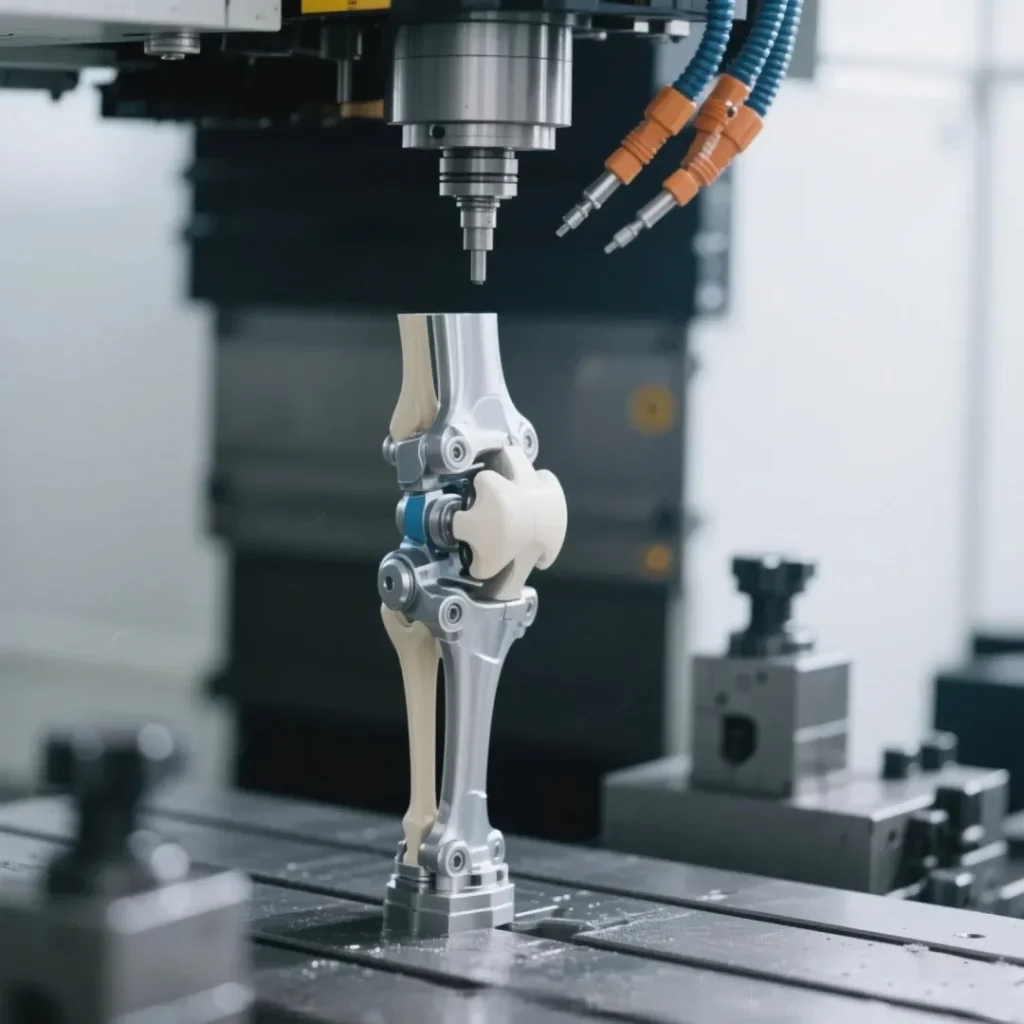

Machining Techniques and Best Practices for Robot Parts

When it comes to machining robotics components, CNC processes are the go-to method because they offer the precision and repeatability needed for complex parts. The key is tailoring the CNC settings and tooling to match the specific material—whether it’s aluminum alloys for robotic arms, stainless steel robot gears, or lightweight plastics in automation. Different materials require different cut speeds, tool types, and cooling methods to achieve tight tolerances and avoid defects.

For aluminum alloys in robotics, optimal parameters include spindle speeds of 10,000-20,000 RPM, feed rates of 0.1-0.3 mm/tooth, and depths of cut up to 2 mm, using carbide tools with coolant to minimize heat buildup and achieve surface finishes as low as Ra 0.4 µm. For CFRP, best practices involve high RPM (15,000-25,000) with low feed rates (0.05-0.15 mm/rev) to prevent delamination, using diamond-coated tools and dust extraction systems for safety and tool life extension up to 500% longer than uncoated tools.

Common challenges in robot part machining include tool wear (e.g., edge chipping on titanium at high speeds), poor surface finishes (Ra >1.6 µm on steels without proper coolant), and maintaining dimensional accuracy—especially with materials like carbon fiber drone parts or tough stainless steel alloys. These issues can be minimized by regular tool inspection (every 50-100 cycles), using appropriate cutting fluids (water-soluble for metals, dry for composites), and leveraging advanced CNC programming that anticipates material behavior, such as adaptive feed control to reduce vibration by 30%.

At XTJ Precision Mfg, we’ve seen how customized CNC solutions boost performance and efficiency. For example, when machining corrosion-resistant materials for cobots, adjusting feed rates to 0.2 mm/rev and tool paths with helical entry reduced heat build-up by 20% and improved part lifespan by 15% in quantified tests under 500-hour operational simulations. Their approach also focuses on scalable production, so whether you need prototypes or full runs (up to 10,000 units), the machining process stays smooth and cost-effective, with defect rates below 1%.

In short, understanding the machinability of nylon prototypes (feed rates: 0.1-0.5 mm/tooth) or composite fabrication for industrial robots comes down to optimizing CNC parameters and picking the right techniques early on. This way, you get parts that meet quality standards without overcomplicating the build process.

Future Trends in Materials for Robotic Machining

Robotics machining materials are evolving fast to meet the demands of smarter, lighter, and more durable components. One key trend is emerging innovations like advanced composites and hybrid materials that offer superior strength-to-weight ratios. For example, carbon fiber reinforced polymers (CFRP) are becoming more common due to their lightweight and high precision, especially in drone and cobot parts.

Another major focus is sustainability. Manufacturers in the U.S. are pushing for eco-friendly materials that reduce waste and energy use during machining. Bioplastics and recyclable composites are gaining attention as companies strive for greener production, aligning with increasing environmental regulations and customer demand.

On the tech side, AI-optimized material selection is reshaping how we prototype and manufacture robotic parts. Machine learning tools analyze performance data to recommend the best materials for specific robotic components faster than ever. This means quicker turnaround times and more precise matching of material properties to application needs, with trends like collaborative robots (cobots) and AI integration driving efficiency in 2025.

Keeping an eye on these trends can help U.S. businesses stay competitive in CNC machining robotics components while embracing efficiency and sustainability.

For more on machining composites like carbon fiber, check out CNC carbon fiber machining.