How CNC Machining is Helping to Advance the Medical Industry

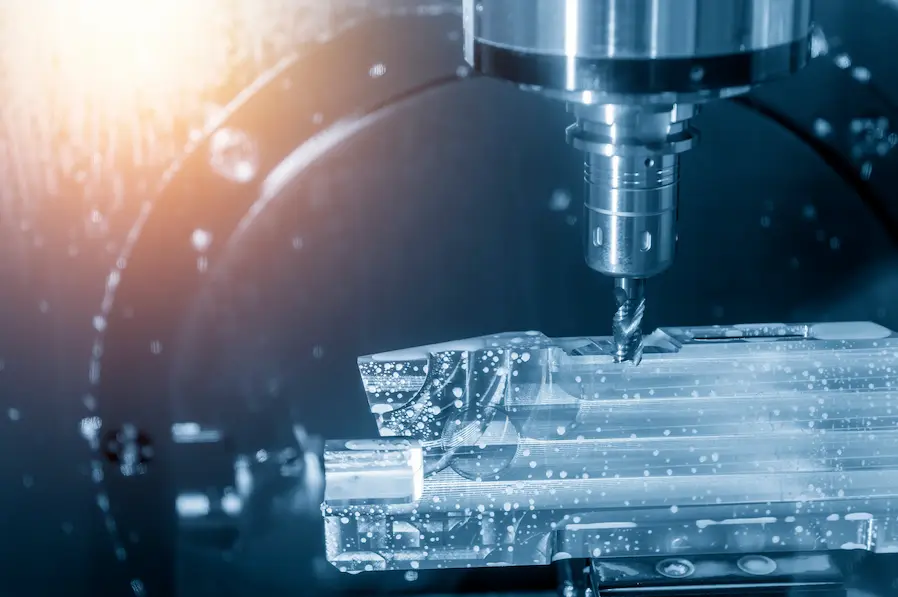

There is little room for error when manufacturing medical devices. This industry is highly regulated and companies must adhere to strict quality standards. These devices often require sophisticated engineering, intricate workmanship, and powerful machinery in order to be created. CNC machining technologies are commonly used to create a wide range of medical products, such as prosthetics and hearing aids. These technologies may be used to produce products in quantity, create intricate designs, and eliminate human error. This advancement of the industry is vital in order to ensure that patients are receiving the best quality treatment possible.

CNC Manufacturing Applications Within The Medical Industry

CNC machining is a critical manufacturing process for many medical applications. The precision and accuracy of CNC machining make it ideal for creating the small, intricate parts needed for medical devices and implants. Medical-grade materials such as titanium and stainless steel can be machined to tight tolerances, ensuring that each part meets the necessary requirements for safety and function. Some of these devices include:

CNC machining is a process that can be used to create surgical instruments with a high degree of precision. In addition, CNC machining can be used to create instruments with a smooth surface finish that is critical for ensuring aseptic conditions during surgery.

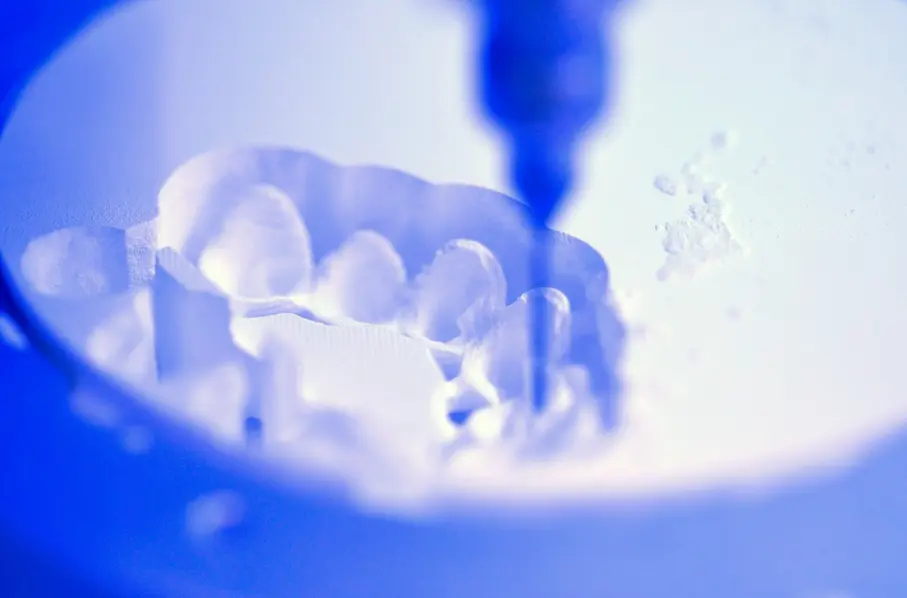

Dental implants

CNC machined dental implants are made from high-quality titanium and are designed to last a lifetime. They are strong, durable, and can withstand the forces of chewing and biting. They are also resistant to corrosion and staining. They work with the jawbone to replace missing teeth and provide maximum comfort to patients.

Orthopedic implants

CNC machined orthopedic implants are medical devices that are designed to replace or support a damaged bone or joint. They are made from biocompatible materials, such as titanium, and are precision-machined to fit the patient’s anatomy.

Cardiac stents

A cardiac stent is a small, metal mesh tube that is inserted into the coronary arteries to keep them open and improve blood flow to the heart. Stents are usually made from stainless steel or a cobalt-chromium alloy. The majority of cardiac stents are created using CNC technology.

Pacemakers

CNC technology is often used in the machining of pacemakers. This is because CNC machines are able to produce very precise and accurate results. This is important when machining pacemakers, as even a small error could lead to serious complications.

Intraocular lenses

CNC machining of intraocular lenses is a precise and delicate process that requires expert knowledge and skill. The lenses are first designed and created using computer-aided design (CAD) software. Once the lenses are finalized, they are sent to a CNC machine where they are cut and shaped to the desired specifications.

The Advantages CNC Machining Offers for the Medical Industry

CNC machining offers a number of advantages for the medical industry. The technology is well-suited for creating small, precise parts and components that are often used in medical devices and equipment. CNC machining can also be used to create prototypes or one-off parts for testing and evaluation. The technology is also well-suited for the mass production of medical parts and components.

Some perks of using CNC machining when manufacturing medical devices include:

Increased accuracy and repeatability of parts

In the medical industry, CNC machines are used to create a variety of parts, including prosthetic devices, implants, and surgical instruments. CNC technology can increase the accuracy and repeatability of these parts by allowing for more precise control over the machining process. This technology can also help to reduce the overall cost of production by reducing the need for manual labor.

Higher speed of production

CNC technology can increase the speed of production of medical parts by allowing the machining of parts to be done more quickly and accurately. In a medical emergency, you can rely on CNC machining for fast and reliable results. CNC machines are designed to work quickly and accurately, so you can get the care you need as soon as possible.

Reduced waste

CNC machining is a highly precise process that can produce complex medical device components with little to no waste. This precision reduces the need for secondary machining operations, which can save time and money in the production process. In addition, CNC machining can be used to produce prototypes or small batches of components, which can help reduce the risk of waste associated with mass production.

Increased flexibility in design

Flexibility in design is important while manufacturing medical devices because it allows for customization of the device to the specific needs of the patient. It also allows for easy modification of the device if necessary, which can improve its efficacy and safety. CNC machining offers increased flexibility in design and allows for more customizability and precision. With CNC machining, parts can be made to exact specifications and tolerances, which gives designers more freedom to create complex shapes and designs.

Improved durability of parts

Durability in manufacturing medical devices is critical because these devices must be able to withstand repeated use and exposure to potentially harsh conditions. This means that the materials used to construct medical devices must be strong and durable, and the manufacturing process must be able to produce consistent, high-quality results. This can be easily provided by using CNC technologies. The ability to create precise parts with CNC machining makes it possible to design medical devices that require a higher level of precision, function, and stability.

Our Medical CNC Machining Services

We provide the most competitive medical implant and instrumentation machining service with a customized and flexible design. We are known for our high-quality level of performance in machining medical implants, instruments, and other similar products.

Professional, Precise, & Reliable

Medical CNC machining is not just about designing or manufacturing medical appliances or instruments. It’s about offering high-grade service that ensures the best patient care. Our precision medical CNC machining services are the best choice for your medical devices’ needs.

Unrivaled quality

Our machining services are customizable and flexible, with unmatched medical implants and instruments’ quality. Our commitment to customer satisfaction ensures that each of our customers will receive the highest-quality service for their needs.

Competitive pricing

We offer competitive pricing for our services. Our team is well-trained in the various machining processes and can use them in order to meet your needs.

Start Your Project With A Free Quote

If you’re looking for a reliable partner to help you get your Medical machining project off the ground, look no further than us. We have a long history of providing precision machining services to clients in a wide range of industries. Let us put our experience to work for you and start your project off on the right foot.