Rapid Tooling Services

Your All-in-One Solution for Fast Molds and Small-Batch Production

- Fast lead time- molds in 7~15 days

- Aluminum or steel molds available

- Support for complex geometries

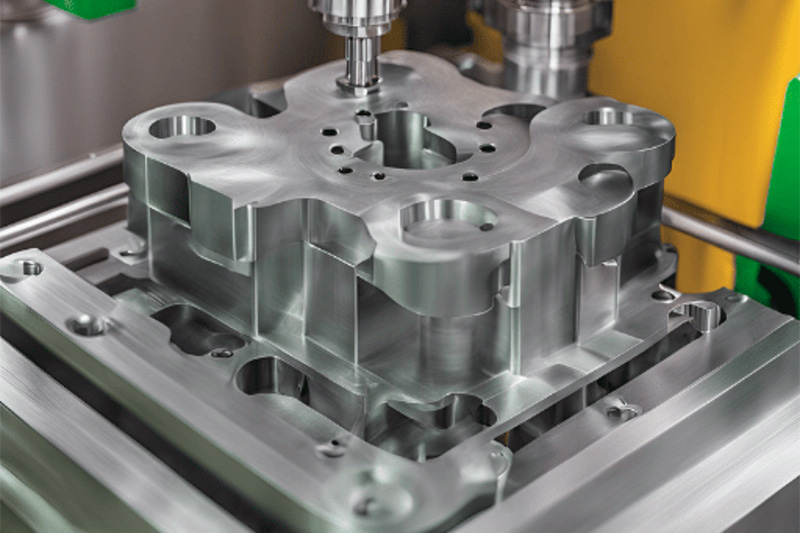

- In-house CNC & EDM machining

- One-stop from mold to final part

Overview of Rapid Tooling Services

XTJ’s rapid tooling services provide a seamless solution that combines fast mold making with low-volume injection molding, helping you accelerate product development and market entry. Our core value lies in speed and flexibility: we deliver high-quality molds and production-ready parts in as little as 10 days, enabling cost-effective design validation and small-batch production without the overhead of traditional tooling.

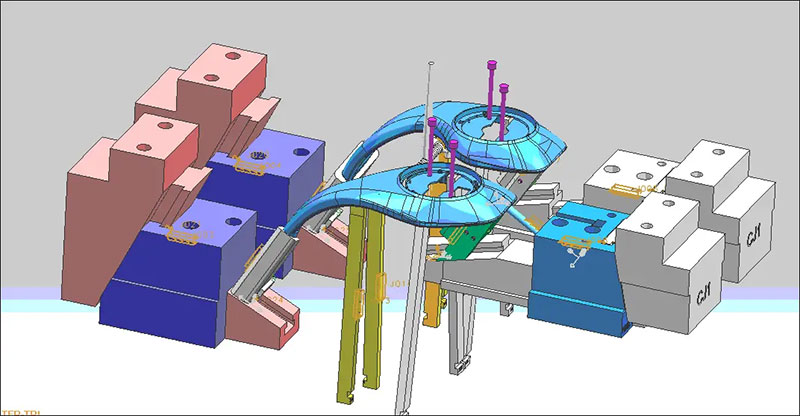

The Complete Rapid Tooling Process

Our integrated process ensures efficiency from mold design to final part production:

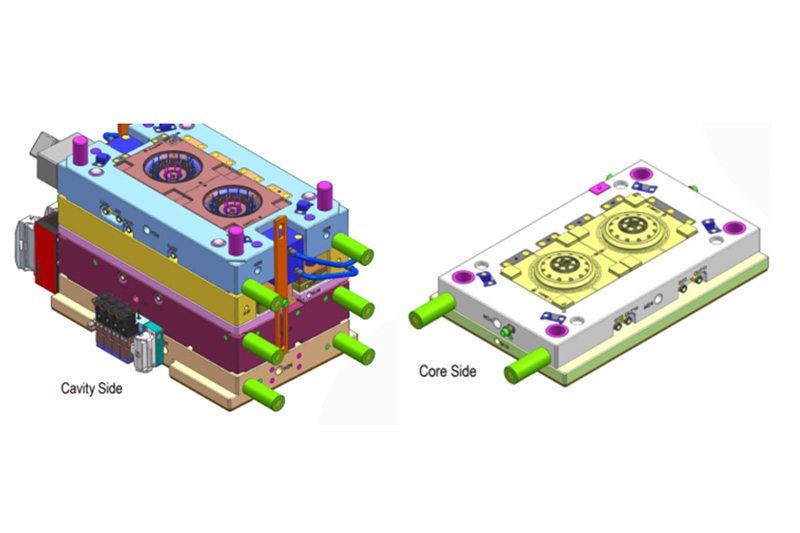

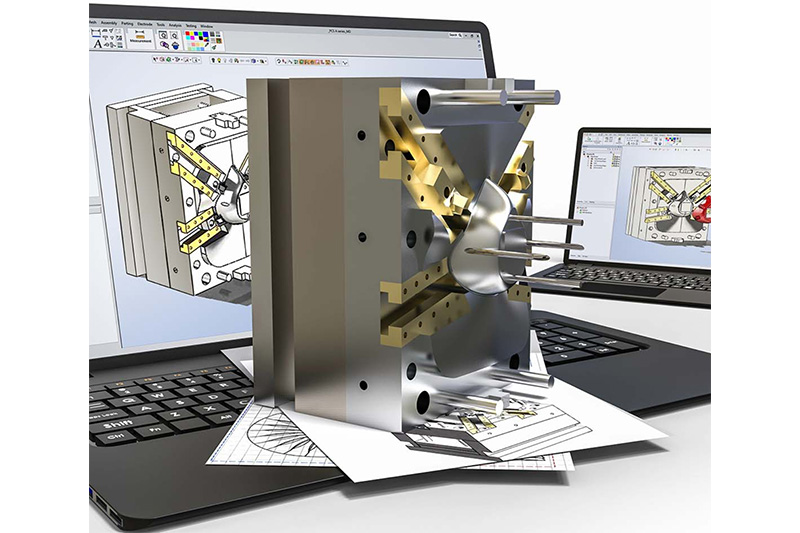

We conduct Design for Manufacturability (DFM) analysis to optimize your part design, followed by rapid mold design using CAD tools.

Molds are crafted using soft steel, aluminum alloys, or other fast-machining materials to reduce lead times.

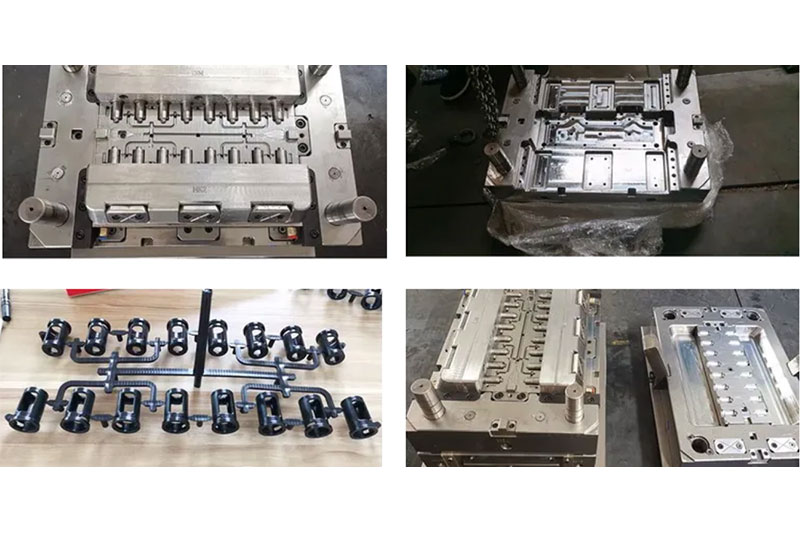

We assemble the mold and perform trial runs to ensure functionality and part quality.

Produce dozens to thousands of parts using the rapid mold, perfect for prototyping or trial production.

Parts are finished (e.g., trimmed, painted) and shipped to your specifications.

Rapid Tooling Breakdown: Mold Making + Low-Volume Production

Our rapid tooling services combine two key stages into one streamlined solution: fast mold making and small-batch injection molding. Here’s how each stage supports your project:

Rapid Mold Making

We use soft steel, aluminum alloys, or other quick-to-machine materials to manufacture injection molds rapidly.

- Goal: Low-cost, short-cycle mold production for design validation.

- Lead Time: As little as 5–10 days.

- Materials: Aluminum for prototyping, soft steel for durability.

- Benefits: Affordable, fast, and adaptable to design changes.

Low-Volume Injection Molding

Using the rapid mold, we produce small batches of parts via injection molding.

- Applications: Suitable for 50 to 5,000 units—ideal for custom production or trial runs.

- Materials: ABS, Polycarbonate (PC), Nylon, and more.

- Benefits: High repeatability, production-quality parts, fast turnaround.

Why Choose XTJ for Rapid Tooling

Discover XTJ’s rapid tooling solutions, specializing in fast mold development, low-volume injection molding, and high-precision production. With over 20 years of expertise, we deliver custom molds and parts in as little as 10 days, empowering you with speed and flexibility to meet tight deadlines and evolving design needs.

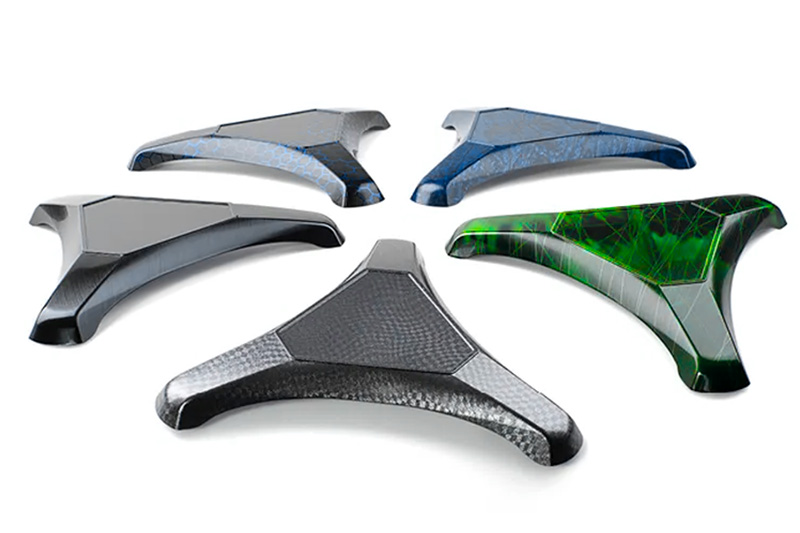

Materials and Industry Applications

XTJ supports a wide range of materials and applications for rapid tooling and production.

Mold Materials

- Aluminum: Lightweight and cost-effective for prototyping.

- Soft Steel: Durable for small-batch runs.

- Hybrid Options: 3D-printed inserts for complex geometries.

Part Materials

- Thermoplastics: ABS, Polycarbonate (PC), Polypropylene (PP).

- Engineering Plastics: Nylon, PEEK for high-performance needs.

- Additives: Colorants, UV stabilizers for enhanced properties.

Key Applications

- Automotive: Prototype components and trial production parts.

- Medical Devices: Custom housings and connectors.

- Consumer Goods: Market testing for new products.

- Electronics: Enclosures and small-batch fittings.

Rapid Tooling vs. Alternatives

Unsure if rapid tooling is right for you? Compare it with other methods—consult our experts for tailored advice!

Feature | Rapid Tooling | Traditional Tooling | 3D Printing |

Process | Fast mold making + injection molding | Conventional mold machining | Layer-by-layer part building |

Lead Time | 10–15 days | 4–12 weeks | 1–5 days |

Cost | Moderate, scalable | High initial investment | Low for small runs |

Volume | 50–5,000 units | 10,000+ units | 1–500 units |

Best For | Design validation, small batches | Mass production | Concept models, prototypes |

Enhance Your Rapid Tooling Results

- Wall Thickness: Keep 1.5–3mm for uniform cooling.

- Draft Angles: Add 1–2° for easy part ejection.

- Parting Line: Minimize to reduce flash.

- Tolerances: Specify ±0.05mm for precision fits.

Get Started Today

Your Partner for Rapid Tooling and Production

Need fast molds and small-batch parts? XTJ’s rapid tooling services deliver speed, flexibility, and precision. Let’s bring your ideas to life!