The sheet metal fabrication process changes flat metal sheets into things you use daily. It is like making shapes from dough, but you use metal instead. You cut, bend, and join the metal to match a design. This industry is the third biggest for jobs in North America. It plays a big part in making cars, planes, and buildings. XTJ Precision Mfg Ltd is a leader in custom sheet metal fabrication. They use advanced tools and have skilled workers for every project.

Key Takeaways

- Sheet metal fabrication changes flat metal sheets into helpful parts for cars, planes, buildings, and things we use every day.

- The steps are design, cutting, forming, joining, and finishing to make strong and exact metal products.

- New tools like CNC machines and smart software help make parts quicker, with less waste and better quality.

- Picking the right metal, like aluminum or stainless steel, changes how strong, heavy, and costly the final product is.

- XTJ Precision Mfg Ltd gives expert help, checks for quality, and delivers fast for both small and big sheet metal jobs.

Importance

Uses

You see things made by the sheet metal fabrication process every day. This process helps shape many things around you. It is used in cars, airplanes, and home appliances. Sheet metal parts help make bridges strong and buildings safe. They also protect electronics and help make medical devices.

- Cars and trucks have metal panels and frames for safety and looks.

- Airplanes need light and strong metal parts for wings and bodies.

- Buildings use metal beams, roofs, and ducts for strength and comfort.

- Electronics have metal cases to protect small parts inside.

- Medical devices use exact metal parts for tools and machines.

- Washers, dryers, and vending machines need metal parts to work.

- Solar panels and wind turbines use metal frames for clean energy.

- Mining and farming machines use strong metal parts for hard jobs.

- Defense gear uses metal for vehicles, armor, and tools.

Tip: When you see a car, a computer, or a hospital bed, you are looking at metal that was shaped and joined with care.

Industries

Many industries need the sheet metal fabrication process to make things you use every day. Each industry needs different shapes, sizes, and finishes.

- Automotive: Body panels, engine parts, and frames.

- Aerospace: Aircraft wings, fuselage parts, and brackets.

- Construction: Beams, columns, trusses, and roofing.

- Electronics: Enclosures, panel boxes, and heat sinks.

- Medical: Surgical tools, tables, and device housings.

- Consumer goods: Appliances, televisions, and lighting fixtures.

- Energy: Solar panel frames, heat exchangers, and wind turbine parts.

- Mining and construction equipment: Platforms, blades, and truck parts.

- Security: Safes, vaults, and camera housings.

- Laboratory and test equipment: Stainless steel tables and wash bins.

Today, new trends are changing this field. Companies use smart machines, robots, and computers to make parts faster and waste less. Many shops recycle scrap metal and use machines that save energy. These steps help the planet and lower costs. When you buy things made with modern sheet metal fabrication, you help support cleaner and smarter ways to make products.

Sheet Metal Fabrication Process

The sheet metal fabrication process changes flat metal sheets into useful things. It works in steps, like following a recipe. Each step builds on the last one. This makes the product strong and ready to use.

Design

The first step is design. You use CAD software to make a digital model. CAD helps you see every detail before making anything. You can find mistakes and fix them. You can also change sizes and check if the part will work. XTJ Precision Mfg Ltd uses CAD tools made for sheet metal. These tools help with things like bend radii and kerf allowances. This stops problems from happening later.

Tip: XTJ checks your design early with DFM analysis. This helps you find problems before making the part. It saves money and uses less material.

Cutting

After design, you cut the metal. This step shapes the flat metal into pieces you need. There are different ways to cut metal. Each way has its own good points:

| Cutting Method | Description | Precision Level | Best Use Cases |

|---|---|---|---|

| Laser Cutting | Uses a laser beam for smooth, detailed cuts | Very High | Thin to medium metals, complex shapes |

| Waterjet Cutting | Uses water and abrasive for cool cutting | Very High | Heat-sensitive or thick materials |

| Plasma Cutting | Uses hot gas to melt and cut metal fast | Moderate | Thick metals, fast jobs |

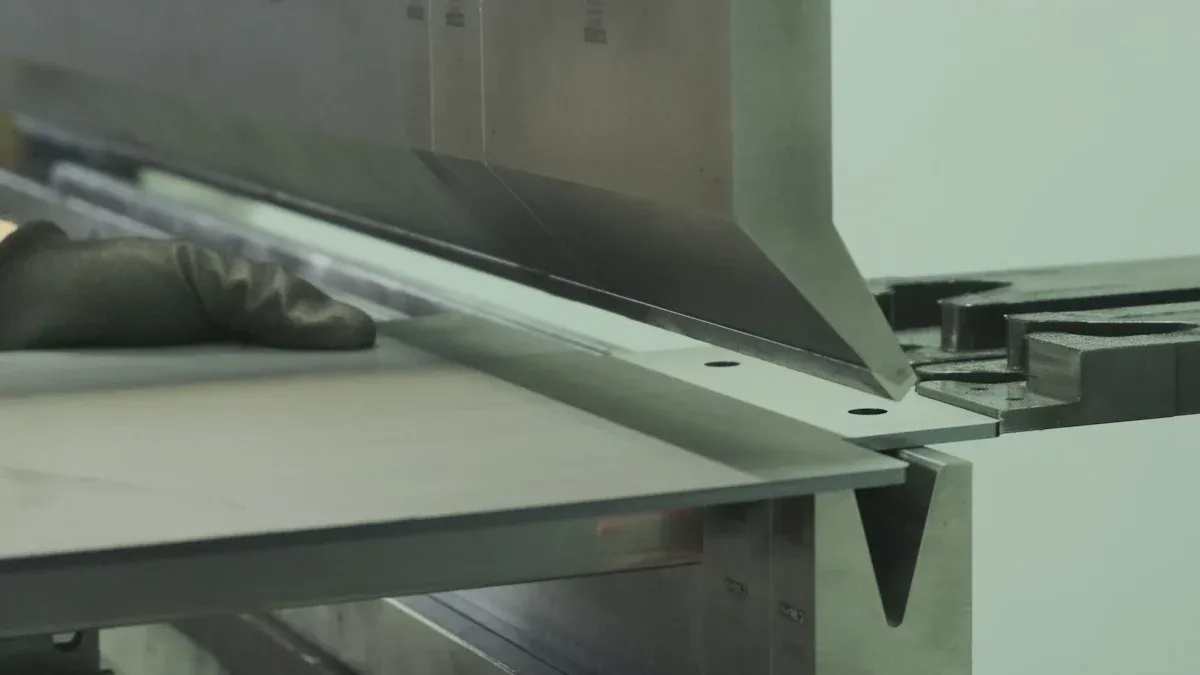

| Shearing | Uses sharp blades for straight cuts | Good for straight cuts | Simple, high-volume parts |

| CNC Machining | Computer-controlled for repeatable, complex cuts | Extremely High | Large or complex projects |

XTJ Precision Mfg Ltd uses advanced CNC machines for all these ways. This makes sure your parts are very exact, sometimes as close as ±0.05 mm. Machines check for mistakes early, so you get good parts every time.

Forming

Next, you shape the metal into its final form. You can bend, stamp, or stretch the metal. Bending uses press brakes to make sharp angles. Stamping presses shapes or patterns into the metal. Deep drawing stretches the metal into deep, hollow shapes.

Note: Forming can change the metal’s thickness and shape. You need to plan your design well. XTJ’s engineers use DFM analysis to stop cracks or warping.

How close the forming is depends on the method and material. Laser cutting can be as close as ±0.05 mm on small parts. Bending is usually between ±0.4 mm and ±0.8 mm. XTJ’s process meets strict rules, so your parts fit together well.

Joining

Now, you join the pieces together. You can use welding, riveting, bolting, or adhesive bonding. Each way works best for certain materials and uses:

| Joining Method | Best For | Advantages | Common Uses |

|---|---|---|---|

| Welding | Steel, aluminum | Strong, permanent joints | Frames, heavy assemblies |

| Riveting/Bolting | Most metals | Easy to put together or take apart | Panels, enclosures |

| Adhesive Bonding | Thin or mixed materials | No heat, smooth finish | Electronics, light parts |

| Soldering | Copper, brass | Low heat, delicate parts | Electronics, plumbing |

XTJ’s team uses the best joining way for your project. Machines help weld and put parts together so they are strong and last long.

Finishing

The last step is finishing. This step makes your part look nice and last longer. You can pick from many finishes:

- Powder coating: Adds a tough, colorful layer that stops scratches and rust.

- Anodizing: Protects aluminum and makes it shiny.

- Zinc plating: Stops steel from rusting.

- Brushing and polishing: Makes the surface smooth and clean.

- Sand blasting: Cleans and gets the surface ready for paint.

XTJ offers all these finishes and more. Machines check the coating and surface quality. Every part meets strict rules like ISO 9001 and AS9100.

Quality check: XTJ uses ZEIZZ CMM inspection and machines to check quality at every step. This means your parts always meet what you need.

The sheet metal fabrication process at XTJ Precision Mfg Ltd uses smart design, exact cutting, careful forming, strong joining, and expert finishing. You get high-quality parts fast, whether you need one or thousands.

Tools and Machines

Sheet metal fabrication needs many machines to make products. Each step uses a special tool. Let’s see the main machines in a modern shop.

Cutting Tools

First, you cut metal sheets into needed shapes. Here are some common cutting tools and what they do:

| Cutting Tool Type | Typical Applications |

|---|---|

| Hand Tools (Snips, Shears) | Simple, precise cuts for small projects or detailed work. |

| Guillotine Cutters | Straight, clean cuts for high-volume jobs. |

| Power Tools (Angle Grinders, Saws) | Cutting thick or hard metals quickly and cleanly. |

| Plasma Cutting | Fast cutting of thick metals, often used in heavy fabrication. |

| Laser Cutting | High-precision cuts for complex shapes, great for detailed work. |

| Water Jet Cutting | Cuts without heat, perfect for heat-sensitive materials and complex shapes. |

| Punching and Blanking | Makes holes or shapes quickly, ideal for mass production. |

XTJ Precision Mfg Ltd uses CNC laser and waterjet cutters. These machines follow digital plans for exact cuts. CNC machines help save material and work fast.

Forming Machines

After cutting, you bend or shape the metal. Forming machines help you do this with accuracy.

- Press Brakes: Bend metal sheets into angles or curves. CNC press brakes let you program bends for perfect results.

- Plate Rolls: Roll flat sheets into cylinders or curved parts.

- Angle Rolls: Bend pipes, tubes, or beams for special shapes.

Modern press brakes use sensors and smart controls. You get the same bends every time. This means your parts fit together well.

Joining Equipment

You often need to join metal pieces together. Here are the main machines for this job:

- Welding Machines (MIG, TIG, Spot Welding): Melt and fuse metal parts for strong joints.

- Riveting and Bolting Tools: Attach parts with fasteners, easy to assemble or take apart.

- Adhesive Applicators: Bond thin or mixed materials without heat.

XTJ uses robots and joining tools for strong joints. This makes sure every part is safe and will last.

Finishing Tools

Finishing tools make your parts look good and last longer.

- Powder Coating Booths: Add a tough, colorful layer that resists scratches.

- Anodizing Tanks: Protect aluminum and add color.

- Polishing and Brushing Machines: Smooth and shine surfaces.

- Deburring Tools: Remove sharp edges for safety and better fit.

XTJ checks every part with ZEIZZ CMM inspection. This makes sure you get safe, high-quality, and nice-looking products.

Tip: The right tools and machines help you get strong, exact, and good-looking sheet metal parts every time.

Materials and Examples

Metals

You can pick from many metals for sheet metal fabrication. Each metal has special features for different jobs. Here are some common metals you might use:

- Aluminum is light and strong. It does not rust and moves heat well. You see it in car parts, planes, and electronics.

- Stainless Steel does not rust or get damaged by heat. It is strong, easy to clean, and looks nice. You find it in kitchen tools, medical gear, and boats.

- Titanium is very strong but not heavy. It does not rust and works in tough places. Planes and hospitals use titanium for important parts.

- Copper and Brass move electricity and heat well. Brass is made from copper and zinc. It is easy to shape and looks good. These metals are in wires, pipes, and decorations.

- Carbon Steel is strong and not expensive. It is good for building big things and machines.

The metal you choose changes how your product works and what it costs. For example, aluminum keeps things light. Stainless Steel makes things strong and stops rust. XTJ Precision Mfg Ltd uses over 20 kinds of metal, like special titanium for planes and stainless steel for hospitals. Their team helps you pick the right metal for your job.

Products

Sheet metal fabrication shapes many things you use every day. Here are some examples you might know:

- UAV Frames are light and help drones fly and carry cameras.

- Medical Enclosures are metal boxes that keep hospital tools safe and clean.

- Electronics Chassis are metal cases that protect computers and gadgets.

- Kitchen Appliances like ovens, sinks, and fridges use metal for strength and easy cleaning.

- Building Parts like beams, stairs, and ducts help buildings stand and move air.

XTJ Precision Mfg Ltd uses smart machines and careful checks to make these things. They follow strict rules like AS9100 for planes and FDA rules for hospitals. You get parts that are safe, work well, and last a long time.

You can master the sheet metal fabrication process by following a few key steps:

- Plan your design and choose the right material.

- Cut and form the metal with care.

- Join parts securely and finish surfaces for safety and looks.

- Check quality at every stage.

If you want to start your own project, XTJ Precision Mfg Ltd offers expert support and fast quotes. Feel free to leave a comment or ask questions below!

FAQ

What is the fastest way to get a custom sheet metal part?

You can send your design to XTJ Precision Mfg Ltd. Their team reviews your file, suggests improvements, and gives you a quote. You get prototypes in 2-5 days and full orders in 1-3 weeks.

Which metals should you choose for your project?

You should pick a metal based on strength, weight, and use. Aluminum is light. Stainless steel resists rust. Titanium is strong and light. XTJ’s experts help you choose the best metal for your needs.

How does XTJ Precision Mfg Ltd ensure quality?

XTJ uses automated machines and ZEIZZ CMM inspection. They check every part during each step. You get parts that meet strict standards like ISO 9001 and AS9100.

Can you order just one part or do you need to order many?

You can order one part or thousands. XTJ Precision Mfg Ltd supports both small and large orders. You get the same high quality for every project.