Aluminum is a lightweight metal that’s often used in construction and manufacturing. It’s also commonly found in everyday items like cookware, beverage cans, and appliances. It is one of the most versatile metals out there. It has a wide range of uses from building materials to electronics.

There are many ways to finish aluminium, such as anodizing or alodining. Both methods produce a protective layer over the surface of the metal. Alodine is a passivation process that works best for the internal parts of your aluminum project, while anodizing provides the best durability for the exterior. Alodine vs Anodize, which one should you choose?

Alodine Is a Corrosion Inhibitor

Alodine is a trading name for a chemical compound that is used as a corrosion inhibitor. It is a water-soluble, organic compound that is used to coat metal surfaces to protect them from corrosion. It is sold in a powdered form that can be mixed with water, or it can be purchased pre-mixed. It is safe for use on all types of metal, including stainless steel, copper, aluminum, brass, and bronze.

Alodine’s primary purpose is to protect your metal against corrosion. It is a type of chromate conversion coating that is applied to the surface of the metal. Alodine works by forming a protective barrier on the surface of the metal that prevents corrosion from occurring. Because it hardens to the same hardness as the metal itself. Alodine not only prevents corrosion but also makes a product more durable.

Alodine chemically bonds to the surface of metals, creating a corrosion-resistant coating. The process does not alter the existing characteristics of the metal, such as weight or hardness. An Alodine finish provides an improvement in corrosion resistance over the original metal, even providing increased protection against chlorine gas.

Clear Alodine Coating for Aluminium

A clear alodine coating is applied to aluminum parts to protect them from corrosion through a chemical reaction called alodic oxidation. The alodine aluminum chromate coating is formed by immersing the aluminum component in a bath of chromic acid and then rinsing it with water. The chemical solution used for the application of alodine is chromic acid. When clear alodine is sprayed, it forms a layer that hardens after it has dried. It is often used for aluminum window frames, wheels, and grills.

Clear Alodine Coating for Stainless Steel

Stainless steel parts are coated with a clear alodine coating that is similar to the coating used on aluminum. This coating creates a uniform, nonporous surface that resists most corrosion and rust. It works through a chemical reaction between the surface of the steel and the alodine that occur at a temperature of 600 degrees Celsius. The coating is then removed after it forms and cleaned. This process forms a protective barrier on the surface of the steel.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.

The Benefits and Limitations of Alodine Finish

Alodine finish is a popular choice for metal parts that boasts numerous benefits. Some examples include:

- Alodine finish is a corrosion-resistant coating that can be applied to a variety of metals. It is suitable for use on steel, aluminum, stainless steel, and titanium.

- Alodine provides a durable, hard finish that can withstand the harsh environments to which many aluminum parts are exposed. It provides an effective barrier against salt spray, humidity, and other corrosive conditions.

- Alodine finish is easy to clean and is resistant to a wide range of chemicals.

- The clear Alodine finish application process is fast, safe, and cost-effective. It can be applied to parts that are designed for use in food or the medical industry.

- Alodine is environmentally friendly and non-polluting. It contains no toxic materials, is readily cleaned and recycled, and has excellent adhesion to metal.

- Alodine coating is an excellent way to create a conductive surface. You can create a small piece of metal or plastic that is much more conductive than the metal itself.

- The process does not alter the mechanical properties of the metal.

However, alodine coating does have some limitations. Some of these are;

- Although it’s safe for the environment, the alodine solution can be particularly toxic to the skin.

- A clear alodine finish is not as durable as other finishes such as powder coating or anodizing.

- Alodine finish can fade over time and may not be as aesthetically pleasing as other finishes.

Whether choosing alodine finish or another finishing process depends on the intended use of the metal. Also, be sure to consider the costs and availability of any materials that you’ll need to use in your project.

Uses of Alodine Coating

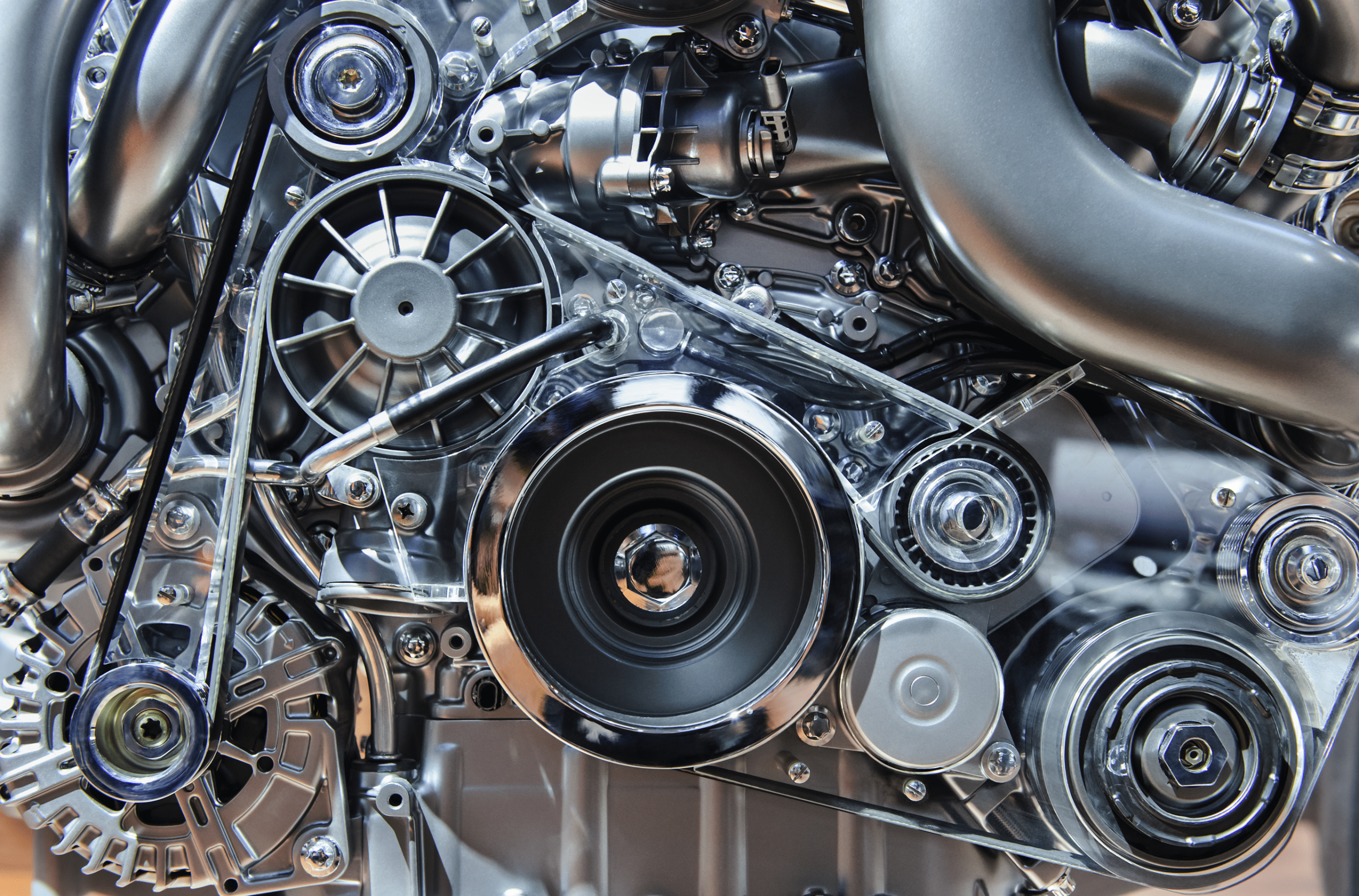

Clear alodine finished aluminum parts have been used in a variety of applications including CNC machining parts, aircraft structures, engine components, electrical devices, automotive interior trim, and more.

CNC Machining

The qualities of aluminum make it a popular choice for CNC machining parts. The process creates metals that are resistant to corrosion without tinkering with the metals’ dimensions. Other benefits of alodine finishing in CNC machining include improved adhesion during priming and the ability to adjust the conductivity of coatings.

Aircraft Industry

Alodine coatings are used in aerospace manufacturing to protect aircrafts from corrosion and oxidation while providing the desired aesthetic finish. Alodine coatings can be applied to airplanes hulls, landing gear, shock absorbers, etc.

Automotive Manufacturing

The most common application of alodine finish in the automotive industry is on bumpers, grilles, and other parts of a car’s exterior body. This helps in making the car look sleek and shiny.

Alodine vs Anodize

There are several different types of finishes that can be applied to aluminum, including alodine and anodize.Alodine is typically used on parts made of aluminum, while anodizing can be applied to steel and other metals as well.

The main difference between alodine and anodize is that alodine is a chemical treatment that is used to prepare the surface of a metal for painting or other finishing processes, while anodize is a process that thickens the natural oxide layer on the surface of a metal to protect it from corrosion.

Alodine vs Anodize? Which one is better for coating Aluminium? The answer is that both finishes have their own advantages and disadvantages, so it is important to choose the finish that best suits the application.

Another difference between anodizing and alodine is that anodizing is a more durable finish that can withstand more wear and tear. Alodine, on the other hand, is not as durable and is not as resistant to wear and tear.

The advantages of alodine finish over anodize are:

- Alodine is cheaper than anodize.

- Clear Alodine can be applied to a wider range of metals.

- Alodine is a less permanent finish than anodize.

The disadvantages of alodine finish over anodize are:

- Anodize will not tarnish and scratch as easily as alodine will.

- Alodine can only be applied to a surface that is free of oils and greases.

- Alodine will not stick to some metals.

Conclusion

Alodine works by producing a layer of silicon dioxide on the surface of the aluminium. This layer helps to protect the material from further corrosion and significantly lengthens the lifespan of the surface. While anodizing is a process that is used to add a protective layer to aluminum and aluminum alloys.

Alodine vs Anodize? Which is the Best Aluminum Surface Treatment? There is no one definitive answer to this question. Some people may say that alodine is still a viable option for treating aluminium, while others may say that it is no longer necessary or recommended.

One factor to consider is that aluminium has become much more expensive than it was in the past. It is also a more valuable metal, and therefore should be treated to ensure that it retains its value and remains corrosion-free.

Learn more about surface finishes: The Complete Guide To Surface Finishes

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.