There are a variety of different finishing techniques that can be used to finish a metal part. The most common are powder coating, painting, and electroplating. Another popular technique, on which we will be focusing in this article, is bead blasting. The process involves propelling small glass or ceramic beads at the part to create a smooth, even finish. It is often used to remove surface imperfections and create a uniform appearance.

What is bead blasting and how does it work? What are the different materials used in this finishing technique? And how can you make use of them to attain great bead-blasted finish results? We will share all of this with you in this thorough guide.

What is bead blasting?

Bead blasting is the process of taking surface coating off metal objects. They may be expensive tools or parts that must have the oxidation layer removed so they can effectively interact with other metals. Basically, beads are propelled towards the object through small-gauge holes in a cup to take the outer material away and add a shiny finish instead.

Bead blasting usage is not restricted to metals. Manufacturers may also use it on other materials such as plastic, glass, and rubber to leave a flawless surface finish.

How does bead blasting work?

Bead blasting is a type of abrasive blasting that uses small beads to clean or etch a surface. The beads are accelerated by a gas such as air, nitrogen, or carbon dioxide. They hit the surface at high speeds, dislodging any dirt or debris. The process can also be used to create a textured surface since texturing makes it difficult for dirt and other contaminants to stick to the surface. The beads can be made either of glass, plastic, or metal.

What metals can be bead blasted?

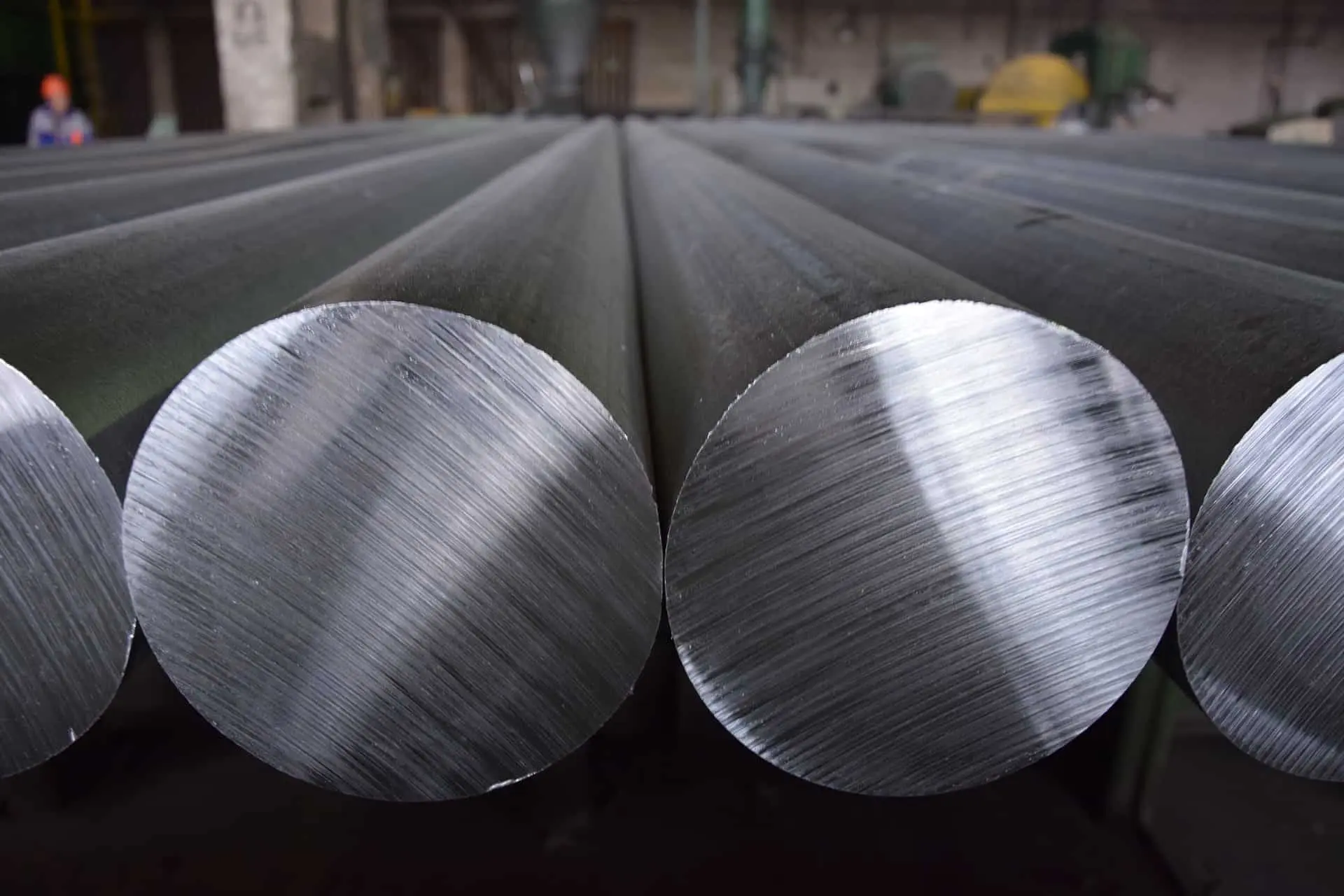

Bead blasting can be used on a variety of metals. The metal is placed in a chamber and small beads are fired at it at high speeds. This high speed abrasion is what gives the metal its matte finish. The technique can be used to remove rust from metal, as well as prepare it for painting. This process can be used on aluminium, titanium, and other metals:

Bead Blasting Aluminum

Bead blasting aluminum is a popular technique for cleaning and polishing aluminium surfaces. There are a number of reasons why you might choose to bead blast aluminum.

Bead blasted aluminum is a great material for a wide variety of applications. It is strong, durable, and lightweight, making it perfect for use in manufacturing, construction, and other industries. Additionally, bead-blasted aluminium is resistant to corrosion and weathering, making it a great choice for outdoor applications.

To choose the correct grade of aluminium for bead blasting, you need to decide what type of bead-blasted finish you want. It will typically be either a phosphated finish or an anodized finish. This can be done by having your aluminium bead blasted by a professional.

Bead Blasting Titanium

Bead blasting titanium is a popular process for removing surface imperfections and imparting a clean, satin finish. The technique uses a stream of small beads to abrade titanium. Bead blasting titanium can be used to achieve a variety of finishes, from a smooth matte to a highly polished mirror-like sheen.

Reasons for which titanium is bead blasted include:

- To remove a thin layer of material from the surface of the titanium to make it smoother.

- To remove a layer of titanium from the surface of the part in preparation for coating.

- To add a semi-permanent colour or finish to titanium.

Bead blasted Titanium has a variety of applications. The clean, clear finish of bead-blasted Titanium is suitable for jewellery, high-performance sporting equipment, parts in marine applications, and heavy-duty industrial components.

The pros and cons of bead blasting

The process of bead blasting has various advantages. However, it can be very abrasive and can damage the surface if not done correctly. What are the pros and cons to consider before proceeding with the technique?

Pros:

- A bead-blasted finish is a matte finish, which many people prefer over a glossy finish.

- It’s quick and cost-effective compared to traditional techniques like sandblasting, electropolishing, etc.

- The finish is durable and long-lasting, making it suitable for high traffic areas such as entrance doors, hardware surfaces, etc.

- It can be applied to a variety of materials

Cons:

- There is a risk of overspray

- Having multiple passes can lead to an uneven surface

- Needs a highly trained operator to produce the finish

- The surface has a glass-like appearance and requires buffing

- The surface is not guaranteed to be free of scratches, swirls, and scratches

Often Asked Questions about Bead Blasting

Is bead blasting better than sandblasting?

There is much debate over whether bead blasting is better than sandblasting. Some say that bead blasting is more precise hence resulting in a cleaner finish. Others maintain that sandblasting is more aggressive and can remove more material.

Bead blasting is a much more gentle process than sandblasting, but it takes much longer. However, the two techniques are similar in the sense that the surface of the part is treated with an abrasive material, and a gas stream forces the abrasive material out of the nozzle at high velocity. Therefore, the choice of the technique depends on the desired results.

How much does bead blasting cost?

The cost of bead blasting will vary depending on the size of the project, the type of blasting media used, and the equipment required.

How do you make bead blast metal?

The process is simple. All you need to do is pick out the type of metal and cleaning method you want to use, then apply the mask, and then blast the metal.