Essential Guide to 5 Surface Finishing Symbol Types in Manufacturing

Surface finishing symbols are essential in manufacturing, guiding how parts are finished to meet specific performance and quality standards. At XTJ Precision MFG, we use these symbols to ensure precision in processes like CNC machining, sheet metal fabrication, and surface treatments. This article explains what surface finishing symbols are, their types, meanings, and their critical role in modern manufacturing, in clear and simple terms.What Are Surface Finishing Symbols?

Surface finishing symbols are markings used on technical drawings to specify how a part’s surface should be finished. Think of them as instructions telling manufacturers how smooth, textured, or polished a surface needs to be. These symbols ensure parts work correctly, look good, and last longer, whether they’re in a car engine, an airplane wing, or a medical device.

The symbols follow standards like ISO 1302 or ASME Y14.36M, which define how to show surface texture, roughness, and finishing methods. They include details like:

-

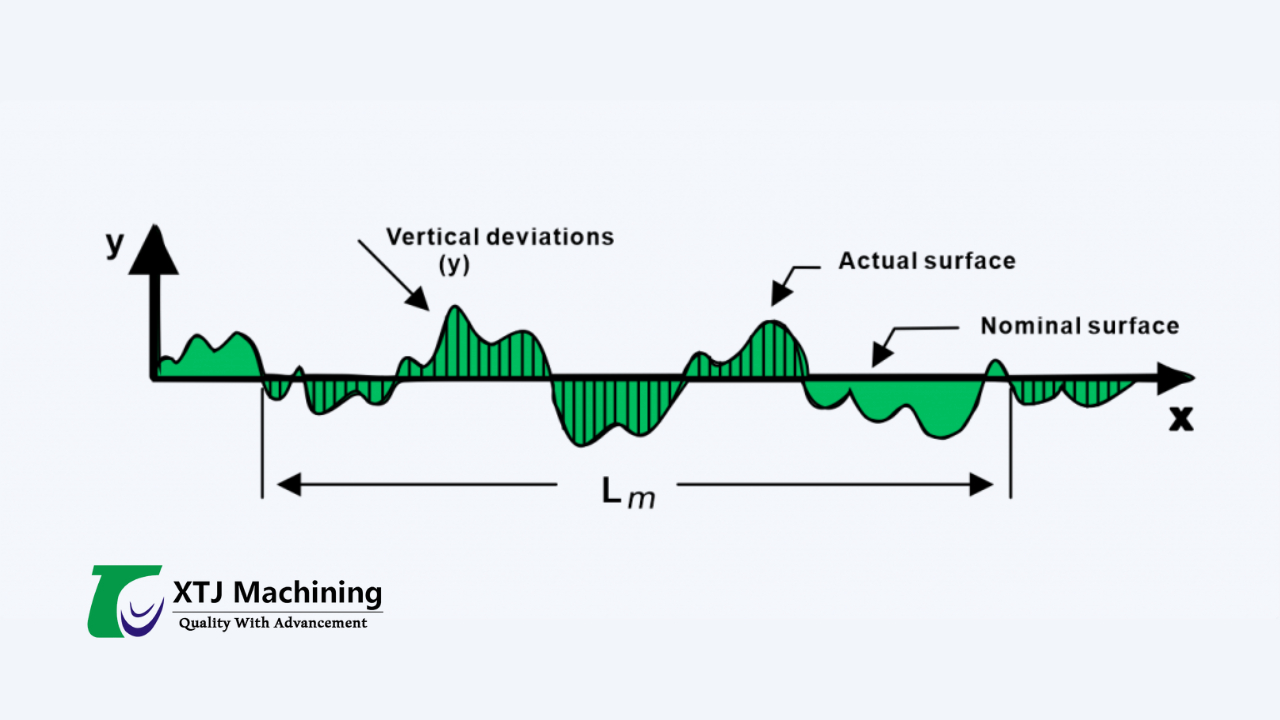

Roughness: How smooth or rough the surface should be (e.g., measured in Ra, micrometers).

-

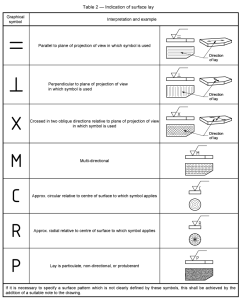

Lay: The pattern or direction of surface texture (e.g., parallel, circular).

-

Finishing Method: Techniques like grinding, polishing, or coating.

Understanding these symbols helps manufacturers produce parts that meet exact specifications for performance and durability.

Common Types of Surface Finishing Symbols

Surface finishing symbols vary by standard and application. Here are the most common types and their meanings:

-

Basic Surface Texture Symbol: A checkmark-like symbol (√) with a horizontal line, indicating a surface finish is required. It may include a number (e.g., Ra 0.8) for roughness.

-

Roughness Value (Ra): Specifies surface smoothness in micrometers (µm). For example, Ra 0.4 means a very smooth surface, while Ra 3.2 is rougher, suitable for less critical parts.

-

Lay Symbols: Indicate the texture pattern, such as:

-

= (Parallel): Texture runs parallel to the drawing view, often from machining.

-

⊥ (Perpendicular): Texture is perpendicular, common in grinding.

-

X (Crossed): Crisscross pattern, often from polishing.

-

C (Circular): Circular texture, typical in turned parts.

-

-

Machining Allowance: A number showing how much material to remove during finishing (e.g., 0.5 mm for grinding).

-

Surface Treatment Indicator: Notes specific processes, like “P” for polishing or “A” for anodizing.

These symbols guide manufacturers in choosing the right finishing process, ensuring parts meet functional and aesthetic requirements.

How Are Surface Finishing Symbols Used in Manufacturing?

Surface finishing symbols are critical in manufacturing, as they communicate precise requirements for part performance. They’re used across processes like CNC machining, sheet metal fabrication, and surface treatments to achieve the desired surface quality. Here’s a detailed look at their applications:

1. Guiding CNC Machining Processes

In CNC machining, symbols specify how smooth a part’s surface needs to be. For example, a Ra 0.4 symbol on a drawing for a medical implant indicates it must be very smooth to avoid irritation in the body. CNC milling or turning can achieve this by using fine tools and slow feeds. For less critical parts, like a machine bracket, a Ra 3.2 might be enough, allowing faster machining. Symbols ensure the machining process matches the part’s purpose, balancing quality and efficiency.

2. Directing Sheet Metal Fabrication

In sheet metal fabrication, symbols guide how metal sheets are finished after cutting or bending. For instance, a stainless steel panel for an aerospace component might have a circular lay symbol (C), indicating it needs turning to create a concentric texture for strength. A crossed lay (X) might be used for a decorative panel, achieved through polishing. These symbols help manufacturers select the right tools, like laser cutters or rollers, to meet design specifications.

3. Specifying Surface Treatments

Surface finishing symbols often indicate specific treatments, like anodizing or plating, to enhance a part’s properties. For example, an aluminum aerospace part might have a symbol noting “A” for anodizing, which adds a corrosion-resistant layer. A copper connector might require a plating symbol to improve conductivity. These instructions ensure parts are treated correctly for durability, wear resistance, or aesthetics, critical in industries like electronics and medical manufacturing.

4. Ensuring Precision in Prototyping

In prototyping with 3D printing or vacuum casting, symbols guide the finishing of test parts. For instance, a vacuum-cast prototype for a medical device might need a Ra 0.8 finish to test its fit and feel. Symbols help manufacturers replicate the final product’s surface quality during prototyping, ensuring accurate testing and faster development.

5. Supporting Quality Control

Symbols are used in quality checks to verify parts meet specifications. Inspectors measure surface roughness (e.g., using a profilometer) to ensure it matches the Ra value on the drawing. For example, a titanium foil implant with a Ra 0.2 symbol must be ultra-smooth to pass medical standards. This ensures consistency across production, whether for aerospace brackets or electronic connectors.

6. Facilitating Communication Across Teams

Symbols provide a universal language for engineers, machinists, and quality teams. A drawing with a perpendicular lay symbol (⊥) tells the grinding team exactly how to finish a part. This clarity reduces errors and ensures everyone understands the required surface quality, from design to production.

Why Surface Finishing Symbols Matter in Manufacturing

Surface finishing symbols are more than just marks on a drawing—they’re critical to producing high-quality, functional parts. Their role in manufacturing ensures parts perform reliably, meet industry standards, and satisfy customer needs. Here’s a deeper look at why these symbols are so important:

1. Ensuring Part Performance

The surface finish directly affects how a part works. A smooth surface (e.g., Ra 0.4) reduces friction in moving parts, like gears in a car engine, improving efficiency and lifespan. A rougher surface (e.g., Ra 3.2) might be better for parts needing grip, like a tool handle. Symbols ensure the finish matches the part’s function, preventing issues like wear or failure in critical applications like aerospace or medical devices.

2. Meeting Industry Standards

Industries like aerospace, automotive, and healthcare have strict standards for safety and performance. For example, a medical implant must have an ultra-smooth surface to avoid tissue irritation, often specified as Ra 0.2 or lower. Aerospace parts need specific finishes to resist corrosion in extreme conditions. Symbols ensure parts meet these standards, passing rigorous inspections and certifications.

3. Improving Durability and Longevity

Surface treatments indicated by symbols, like anodizing or plating, protect parts from wear, rust, or chemical damage. For instance, an anodized aluminum part resists scratches in harsh environments, while a plated copper connector lasts longer in electronics. Symbols guide these treatments, ensuring parts are durable and cost-effective over time.

4. Enhancing Aesthetics

Surface finish affects a part’s appearance, which matters for consumer products or visible components. A polished finish (X lay) on a stainless steel appliance creates a sleek look, while a brushed finish (parallel lay) adds a modern texture. Symbols help manufacturers achieve the desired look, boosting product appeal in markets like automotive or electronics.

5. Streamlining Production Efficiency

Symbols clarify exactly what’s needed, reducing guesswork and errors. For example, a machining allowance symbol (e.g., 0.5 mm) tells the team how much material to remove, preventing over- or under-finishing. This precision speeds up production and minimizes waste, saving time and costs in processes like CNC machining or sheet metal fabrication.

6. Supporting Innovation in Prototyping

In prototyping, symbols help create test parts that mimic the final product’s surface. For example, a 3D-printed prototype with a Ra 0.8 finish can test how a part feels in a medical device. Vacuum-cast parts might use specific lay patterns to test textures. Symbols ensure prototypes are accurate, speeding up development for new products in industries like healthcare or aerospace.

7. Facilitating Global Collaboration

Surface finishing symbols are standardized (e.g., ISO 1302, ASME Y14.36M), making them a universal language for global manufacturing. A drawing created in one country can be understood by a factory in another, ensuring consistency. This is vital for industries with international supply chains, like electronics or automotive, where parts are made and assembled worldwide.

Your Partner for Precision Surface Finishing

Surface finishing symbols are key to creating parts that are functional, durable, and visually appealing. By specifying exact surface requirements, they guide manufacturers to produce high-quality components for industries like aerospace, electronics, and healthcare. With the right finishing techniques and a clear understanding of these symbols, you can achieve parts that meet both technical and aesthetic needs.

XTJ Precision MFG is your trusted partner for precision manufacturing, offering expertise in CNC machining, sheet metal fabrication, and surface treatments. Our experienced team and advanced equipment ensure your parts are finished to the highest standards, whether you need a polished medical implant or an anodized aerospace component. Contact us today at [email protected] or call +86 188 2344 0850 to discuss how we can support your next project.