Vacuum Infusion & Casting Services

Precision Solutions for High-Performance Parts

- 20+ Years of Expertise

- In-House Mold Design & Prototyping

- Advanced Quality Inspection

- Rapid Lead Times & Scalable Batches

Mastering Vacuum Technologies

XTJ is fully capable of handling your vacuum casting and silicone molding needs. With years of expertise in the field, we can fabricate your plastic parts to the highest standard, as well as cost-efficient and with fast turnarounds.

Vacuum casting is a great method to make rigid or flexible parts, and is ideal for high quality prototypes, function testing, concept proofing and display demos. Urethane casting parts can be made from a few to hundreds as required.

Contact us today for more information about our casting services.

What is Vacuum Casting?

Vacuum casting is a manufacturing technology that uses a vacuum to draw liquid casting material into a mold. It differs significantly from injection molding, which pushes liquid material into a mold using a screw.

The process of vacuum casting offers significant advantages, and is particularly useful for parts that have undercuts or fine details.

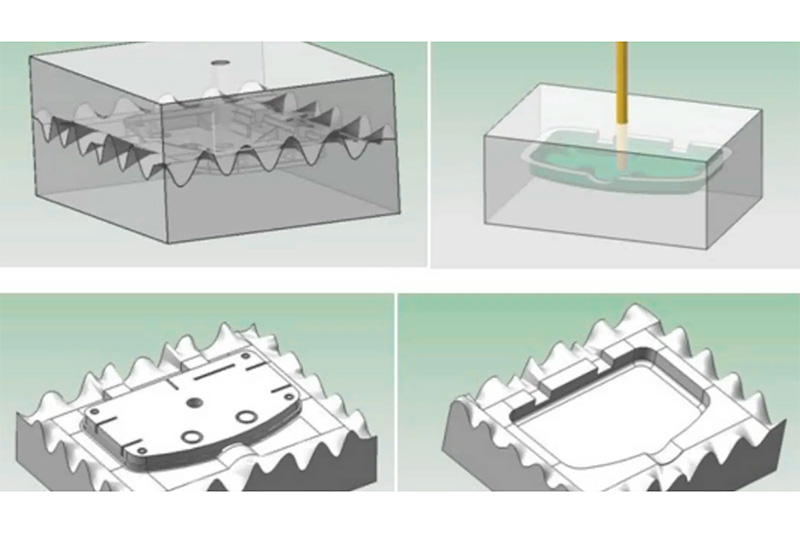

The process starts with a master model, which XTJ creates using one of its CNC machining centers — though 3D printing can also be used. This master model is then immersed in liquid silicone, which is cured and becomes the mold.

Once it has been cut and the master model removed, the silicone mold can be put to use. This stage involves pouring casting resin into the mold, as the vacuum removes bubbles and air pockets to ensure a smooth finish.

The resin part is then cured in an oven and removed from the silicone mold after cool down, which can be reused around 20 times.

Each cast part is an exact copy of the original master model. It’s a perfect solution for rapid prototyping and making small batches of quality parts.

Vacuum Casting Process

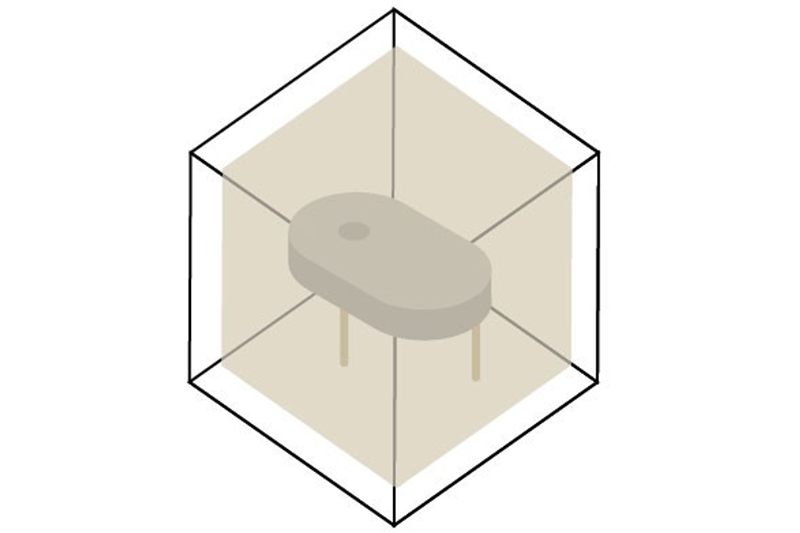

Master model made by3D printing or CNC machining

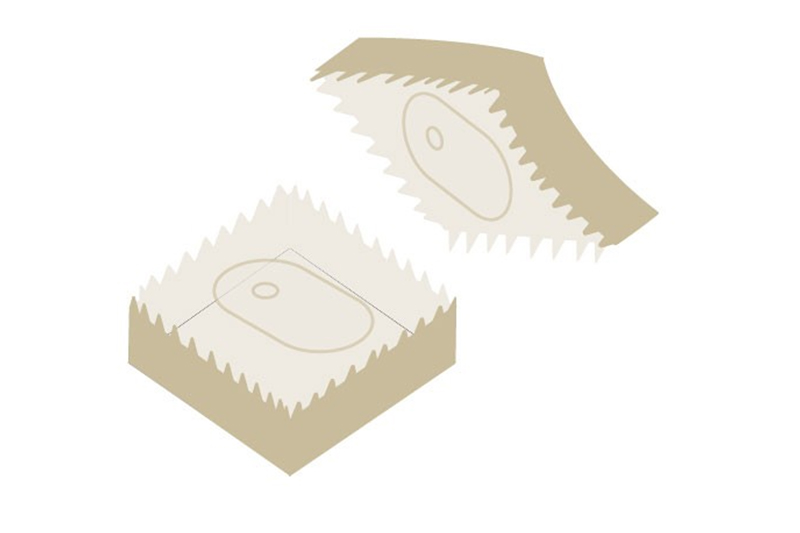

Casting frame is filled withsilicone to produce the mold

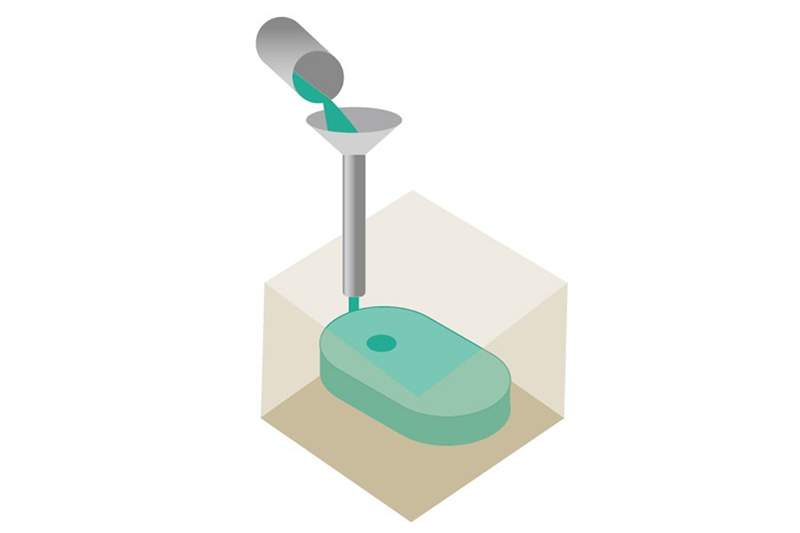

Polyurenthanes is poured into themolds in the vacuum casting machine

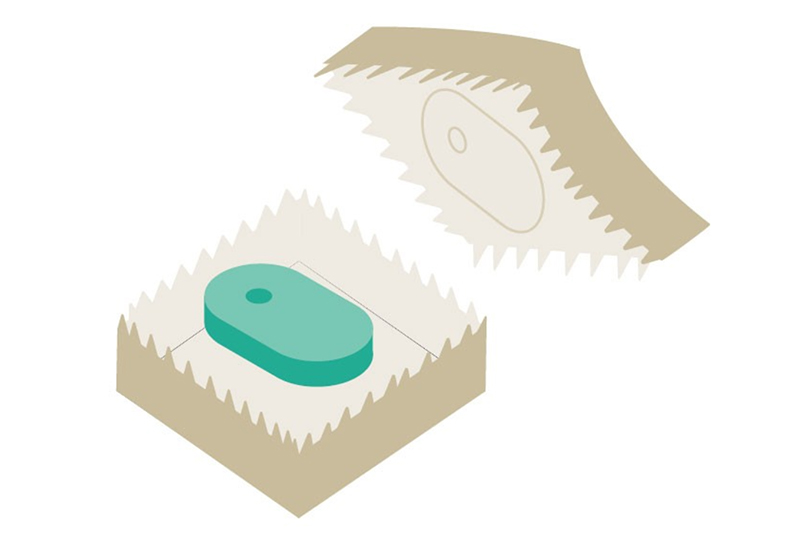

The part is cured andto be accomplished

Get the mold core and cavity

Perform the other surfacetreatment as per request

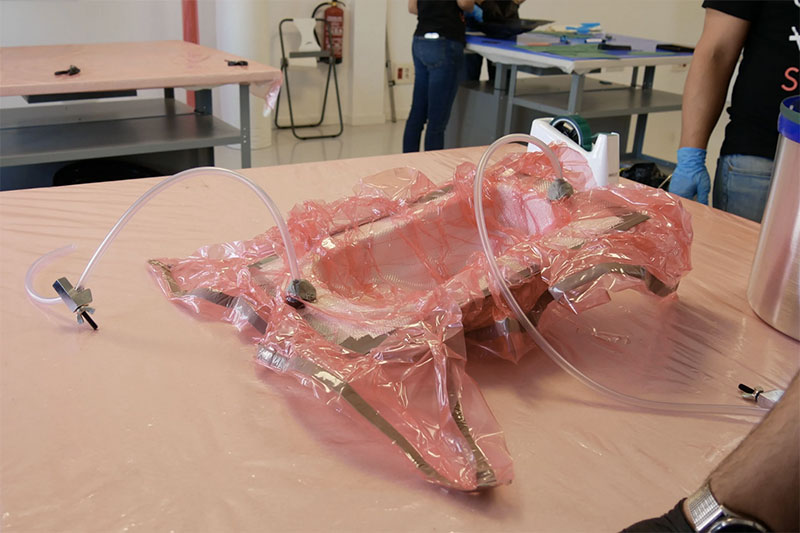

What is Vacuum Infusion?

Imagine creating a super-strong, lightweight part—like a car panel or a boat hull—without any air bubbles. That’s what vacuum infusion does! It’s a process where we lay down dry materials like carbon fiber in a mold, cover it with a special bag, and use a vacuum to suck in liquid resin. The vacuum ensures the resin spreads evenly, creating a solid, high-performance part with almost no imperfections. It’s perfect for bigger, structural components that need to be both strong and light.

Process Steps:

- Lay dry fibers (like carbon fiber) in a rigid mold.

- Seal with a vacuum bag and apply negative pressure.

- Infuse resin (like epoxy) and cure under controlled heat.

- Trim and inspect with precision tools.

Which Process Fits Your Needs?

Here’s a clear comparison to help you choose the right vacuum technology for your project. Not sure? Talk to our experts for a free evaluation!

Feature | Vacuum Infusion | Vacuum Casting |

Materials | Carbon Fiber, Fiberglass, Epoxy Resin | PU Resins, Rigid/Flexible Plastics, Colored Options |

Applications | Automotive Panels, Drone Frames, Aerospace Shells | Functional Prototypes, Housings, Low-Volume Runs |

Part Type | Structural, High-Strength Parts | Detailed, Visual/Functional Models |

Production Volume | Medium to Large Batches | Small Batches (5–100 Units) |

Finish | Matte or Raw Composite | Smooth, Detailed, Paintable |

Best For | Strength and Durability | Appearance and Testing |

Advantages of Vacuum Infusion & Casting

Fast Turnaround

XTJ can provide up to 20 parts in 15 days or less, depending on part specification and volume.

Affordability

Silicone molds are less expensive than the tooling used for injection molding, resulting in low prices.

Capable of producing large parts

Depending on the type of equipment used, vacuum casting can to create very large parts.

Superior surface finish to injection molding

The vacuum process removes air bubbles and allows the material to capture fine details.

Color options

Coloring pigments can be added to the resin for a variety of color options.

Repeatability

Silicone molds can be used around 20 times before they need replacing.

Industries & Applications of Our Vacuum Infusion & Casting Services

At XTJ Precision, our vacuum infusion and casting processes are widely applied across various industries to manufacture high-performance fiberglass-reinforced plastic (FRP) components. These services are ideal for:

We supply lightweight, corrosion-resistant FRP parts for EVs and traditional vehicles, including battery box covers, bumpers, air deflectors, and fenders.

FRP components made via vacuum infusion reduce weight while improving durability—ideal for electric vehicle platforms.

Durable fiberglass enclosures and exterior shells designed to withstand extreme outdoor environments.

We support early-stage product design with visual prototypes, concept models, and low-volume custom casings.

Ideal for pilot testing, market validation, or niche product runs before full-scale production.

Present your product with high-finish FRP samples—perfect for investor pitches and exhibitions.

How We Ensure Quality

Our process integrates cutting-edge technology and rigorous checks:

Material Verification

Inspect raw inputs with precision gauges.

In-Process Control

Real-time monitoring during production.

Final Validation

Zeiss CMM and optical systems for dimensional accuracy.

Traceability

Full documentation for every component.

Your Precision Parts Partner

Ready to bring your project to life? XTJ delivers vacuum infusion and casting with unmatched accuracy and speed.