Tungsten, element 74 of the periodic table, has come a long way since its early use as a material for filaments in lightbulbs. This silvery-white lustrous metal is becoming more present in the industry thanks to the alloying process – that is, the ability to add metallic elements together to create new, improved materials known as alloys. Tungsten can act as both an alloy base and an alloying element, and this article will compare elemental tungsten with its most common alloy, tungsten carbide. Both forms can be found in numerous applications, and this article will help distinguish each type of tungsten from the other by comparing the physical, mechanical, and working properties of each. By doing so, this article aims to help designers make more informed material choices, as well as show the unique characteristics of these advanced metals.

Graphic illustration of element 74, tungsten, from the periodic table of the elements.

Tungsten and its alloys are prized for their strength and stability over temperature.

Image credit: concept w/Shutterstock.com

Tungsten

Originally dubbed ‘wolfram’ in 1779, tungsten (tung sten, or “heavy stone” in Swedish) is a dense metal first isolated in the late 1700s. Since then, it has become increasingly important to the field of material science, as it shows some interesting and valuable properties. These includes excellent high temperature resilience, the lowest expansion coefficient of any metal, the highest melting point of any metal (3370°C/6100°F), the lowest vapor pressure of any metal, high moduli of compression and elasticity, good electrical conductivity, and a high density (19.25 g/cm3), just to name a few. When alloyed with other metals, tungsten can provide some of these properties to the resulting alloy, especially its high strength and resilience. There are, therefore, many tungsten alloys (explained further in our article on the types of tungsten alloys), as well as many other metals such as steel and aluminum that benefit from the addition of tungsten to them.

Tungsten is notoriously difficult to work with while in its impure state, as it’s low ductility predisposes it to shatter. It is brittle at room temperature, and so must be cut/formed well above its transition temperature and cannot be cold-tooled. Tungsten can be ground, joined, milled, riveted, spun, stamped, and turned, but it must be handled with great care, as it is prone to breaking and is generally an expensive material to work with. Pure tungsten is much easier to work, being able to be cut with a hacksaw and is much less brittle, but this pure state is more expensive and is reserved for niche applications. It has good corrosion resistance, only attacked by mineral acids, and oxidizes in the presence of oxygen at high temperatures. An interesting fact about tungsten is that when in a powder state, tungsten can spontaneously ignite in the presence of air (so, machinists beware).

Tungsten is useful for glass-to-metal seals, as its thermal expansion coefficient is on par with borosilicate glass, and finds many uses in lamp filaments, television tubes, electrical contact points, x-ray targets, heating elements, and other high-temperature applications. It is most popular usages are in dry lubricant (tungsten disulfide) and alloys such as high-speed tool steels, hard metal, and of course tungsten carbide – but more on that in the next section.

Tungsten Carbide

Tungsten carbide is an alloy made of tungsten and carbon, made by heating tungsten powder with carbon and hydrogen at 1,400 – 1,600°C (2,550 – 2,900°F). The resulting alloy is 2-3 times as rigid as steel and has a compressive strength surpassing all known melted, cast, and forged metals. It is highly resistant to deformation and keeps its stability at both extreme cold and hot temperatures. When in its monocarbide form (chemical formula of WC), tungsten carbide rivals diamond for the hardest known material. Its impact resistance, toughness, and resistance to galling/abrasions/erosions are exceptional, lasting up to 100 times longer than steel in extreme conditions. Its properties place tungsten carbide in the metal-like substances since it is technically a ceramic cement of tungsten, carbon, and some binder (often cobalt), which is also why it cannot be heat-treated in any way. It has a density of 15.7 g/cm3 and is generally not the best electrical conductor; however, it conducts heat much faster than tool steel.

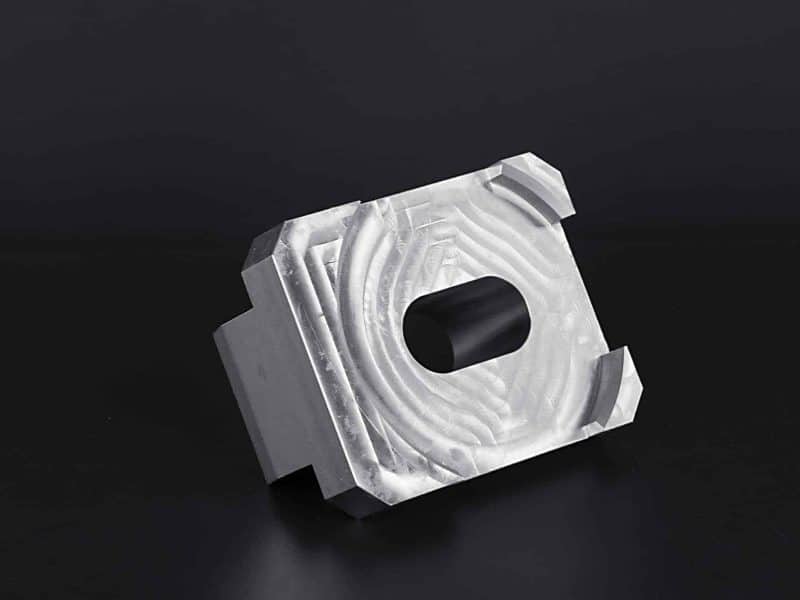

It is incredibly difficult to machine tungsten carbide, as most machine bits and tools are made of tungsten carbide themselves. Tungsten carbide is generally only milled or lathed and is done so when in its soft, or “green” state, and can only be done with diamond-coated bits. It can also be cast and rapidly quenched to form an extremely hard crystal structure. Tungsten carbide is invaluable in making hardmetal, which is a form of tungsten carbide, as well as making mill products, high-speed tools, military weapons, armor, and other rugged applications.

Table of Contents

Is Tungsten Carbide a Metal?

No, tungsten carbide is not a metal. It’s a metal and ceramic hybrid composed of tungsten and carbon atoms. The resulting material exhibits metal-like properties such as high hardness, strength, and thermal conductivity, but its structure is more akin to that of a ceramic.

Tungsten vs. Tungsten Carbide

Tungsten is a chemical element, while tungsten carbide is a compound composed of tungsten and carbon. Tungsten carbide is known for its exceptional hardness and wear resistance, making it a widely used material for cutting tools, jewelry, and various industrial applications, whereas pure tungsten is often utilized in electrical and high-temperature applications due to its unique properties.

Most people will confuse tungsten and tungsten carbide, as tungsten carbide is the most widely understood form of tungsten available. However, there are some niche use cases for its pure form, and this section will contrast tungsten and tungsten carbide to illustrate how they differ. Below, in Table 1, is shown several mechanical properties of each material, and their comparison should give readers a better idea as to when to implement one material over the other. Note that mono tungsten carbide (WC) is used for this comparison, but more alloys exist.

What Are the Properties of Tungsten Carbide and Tungsten?

The properties of tungsten carbide and tungsten are modulus of elasticity, shear modulus, tensile yield strength, thermal conductivity, and hardness (Rockwell A). Below, we compare the properties of each.

Table 1: Comparison of Material Properties Between Tungsten and Tungsten Carbide

Material properties

Tungsten (Metric)

Tungsten (English)

Tungsten Carbide (Metric)

Tungsten Carbide (English)

Modulus of Elasticity

400 GPa

58000 ksi

669-696 GPa

97000-100000 ksi

Shear Modulus

156 GPa

22600 ksi

260-298 GPa

37700-43220 ksi

Tensile Yield strength

350 MPa

50800 psi

140 MPa

20300 psi

Thermal Conductivity

163.3 W/m-K

1133 BTU-in/hr-ft²-°F

28-88 W/m-K

194-610 BTU-in/hr-ft²-°F

Is Tungsten Carbide Stronger Than Tungsten?

Yes, tungsten carbide is generally stronger than pure tungsten. Tungsten carbide is a compound made by combining tungsten with carbon to form a very hard and durable material. This compound exhibits exceptional hardness, wear resistance, and strength, making it suitable for various industrial applications, including cutting tools, abrasives, and jewelry.

Tungsten already has a large elastic modulus, one larger than most steels; tungsten carbide has an even greater elastic modulus, showing its impressive rigidity. Generally, materials stiffness correlates with a large elastic modulus, and the values shown in Table 1 prove why tungsten carbide is second only to diamond in elastic resilience. Its elastic modulus is almost 700 GPa, which is on the heels of diamond (elastic modulus of 1000 GPa),

which shows both its resistance to deformation as well as its tendency to shatter when worked.

The shear modulus is the ratio of shear stress to shear strain within a test specimen and is often referred to as the modulus of rigidity. It is inexorably connected to elastic modulus, as they are derived from the same equations and are both measures of rigidity (one is in response to elastic, or linear stresses, versus shear, or cross-sectional stresses). The values in Table 1 are yet more evidence to show the impressive resistance tungsten provides. For reference, most steels have a shear modulus around 80 GPa, which is only half that of tungsten and a third that of tungsten carbide’s shear modulus.

Most designers select materials based on their strength, naturally. Both tungsten and tungsten carbide are known to be rugged, extremely tough metals – so why are their tensile strengths so low? The answer is due to these materials being brittle by nature and shows an interesting material science phenomenon. Due to their molecular rigidity, brittle materials are much, much stronger in compression than they are in tension (think brick walls: they can bear thousands of pounds in compression but have you ever seen a brick truss before?). This principle becomes clear when examining the compressive strength of these materials, especially the less metallic tungsten carbide: it has a compressive strength of 2683 MPa at room temperature and retains its strength through extreme temperature changes. This same characteristic cannot be said for steel, where its compressive strength is first of all much lower and secondly, fluctuates based on temperature. Knowing this fact, it is abundantly clear that tungsten should never be used in tensile applications but is a top contender in compressive applications.

What is the Tensile Strength of Tungsten Carbide?

The tensile strength of tungsten carbide can vary depending on the specific composition, grain size, and manufacturing processes. Generally, the tensile strength of tungsten carbide falls near 140 MPa (20300 psi).

Is Tungsten Carbide Conductive?

No, tungsten carbide is not conductive. While tungsten itself has relatively high electrical conductivity, the addition of carbon to form tungsten carbide reduces its conductivity. The presence of the carbon atoms in the compound disrupts the metallic bonding, hindering the flow of electrons.

Tungsten, thanks to its inherent temperature stability, is, therefore, a great choice for thermal applications such as filaments, tubes, and heating coils as it will retain its properties even under such intense thermal stress. So, while the value itself is on par with other metals, it can provide this thermal conductivity in a greater range of temperatures, making it more useful.

Thermal conductivity is an important measure when using a material in high-temperature environments: these could be in electrical applications where a large current creates a temperature differential, or in high-speed applications where friction produces heat. This value shows how much heat can be conducted, or can pass through a material, and has important implications for a material’s stability under conditions involving temperature changes. While some steels have similar thermal conductivities to the values shown in Table 1, they are often not used in extreme temperatures, as drastic temperature changes will alter the steel’s properties and may cause issues in the design.

What is the Hardness of Tungsten?

Tungsten is a very hard and dense metal with a hardness of 66 on the Rockwell A scale. This indicates a high level of hardness, contributing to tungsten’s suitability for applications requiring wear resistance and durability.

Tungsten’s exceptional hardness contributes to its suitability for various applications, including the production of cutting tools, high-temperature applications, and as an alloying element in materials such as tungsten carbide, which is even harder and widely used for its wear-resistant properties.

Hardness is a useful comparative value, as harder materials can cut into softer materials, and is why tungsten carbide is popular in carbide tipped bits. When a material is described as “hard”, it means it is resistant to changes in its surface, such as scratches, dimples, pitting, etc. It is a measure derived from indentation tests, where an indenter (often a small sphere) is pushed into a material with a standardized force range, and its behavior is recorded. There are many different hardness scales, as certain indentation machines are used only for stronger materials. The Rockwell A scale (shown in Table 1) uses a spheroconical diamond at its indenter, and it reserved for exceptionally hard materials such as tungsten carbide. The high hardness of both of these materials is expected but is still notable and it shows why tungsten carbide can cut even hardened steels.

While pure tungsten does not have the toughness of its alloys, tungsten carbide does not have the unique physical properties of its pure form, making these materials equally useful. Understanding what kind of specifications are needed for your project is necessary before choosing between tungsten and tungsten carbide, as they are both specialized for different applications. As always, a conversation with your supplier will provide you with the best knowledge on which to use, or if there is a less expensive option worth consideration.

How Hard is Tungsten Carbide?

Tungsten carbide is extremely hard, and its hardness measured on the Rockwell A scale is 90. Its level of hardness is second to diamond.

This exceptional hardness contributes to the wear resistance and durability of tungsten carbide, making it a popular choice for various industrial applications, including cutting tools, drilling equipment, and wear-resistant components.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.