CNC Turning Parts

XTJ offers custom CNC turning parts to meet various industry requirements.

We can produce CNC-turned parts that are fabricated for aerospace, medical, automotive, electronics, and more industries.

Cost-Effective CNC Turning Parts Solution

XTJ uses CNC turning for producing different parts such as CNC turned fasteners, screws, nuts, arrow archery broadheads, fishing broadheads, fittings, rivets, studs, spare parts, machinery parts, mechanical parts, metal housings, and more.

All these CNC turned parts are manufactured using a wide range of materials. We use aluminum alloy, stainless steel, brass, copper, steel alloys, and other metals.

HM can also provide customized CNC turning parts for different industries such as military and defense, medical, aerospace, mechanical, automotive, electronics, and more.

Our CNC turned parts are also available in custom surface treatments like polishing, anodizing, brushing, zinc-plating, etc.

CNC Turning Parts Expert in China

CNC Turning Part Application

CNC turning is a flexible production process commonly used in different industries such as engineering, aerospace, medical, automotive, and more. Here in HM, we used advanced CNC turning for producing different kinds of metal components such as the following:

Aluminum Components. We offer CNC turning services for manufacturing aluminum components. HM commonly used aluminum materials because of their strong and lightweight properties. Aluminum components are suitable for different applications.

Steel Components. HM uses CNC turning for steel component production. We use steel materials because of their strong and economic properties. CNC turned steel parts are widely used in automotive and aerospace.

Brass Components. CNC turning can produce different brass components for commercial products such as hardware parts, electrical contacts, and more.

CNC Turning for Producing

Different Components

The CNC turning process uses a specialized CNC lathe machine. It uses a cylindrical material block to be shaped into the desired part design.

Here in XTJ, we are capable of producing single axis and cylindrical parts through CNC turning. Among these parts includes:

Sleeves

Shafts

Disks, and more

XTJ CNC turning capabilities can be used together with CNC milling to produce different parts with complex shapes.

Precision CNC Turning Parts Material Selection

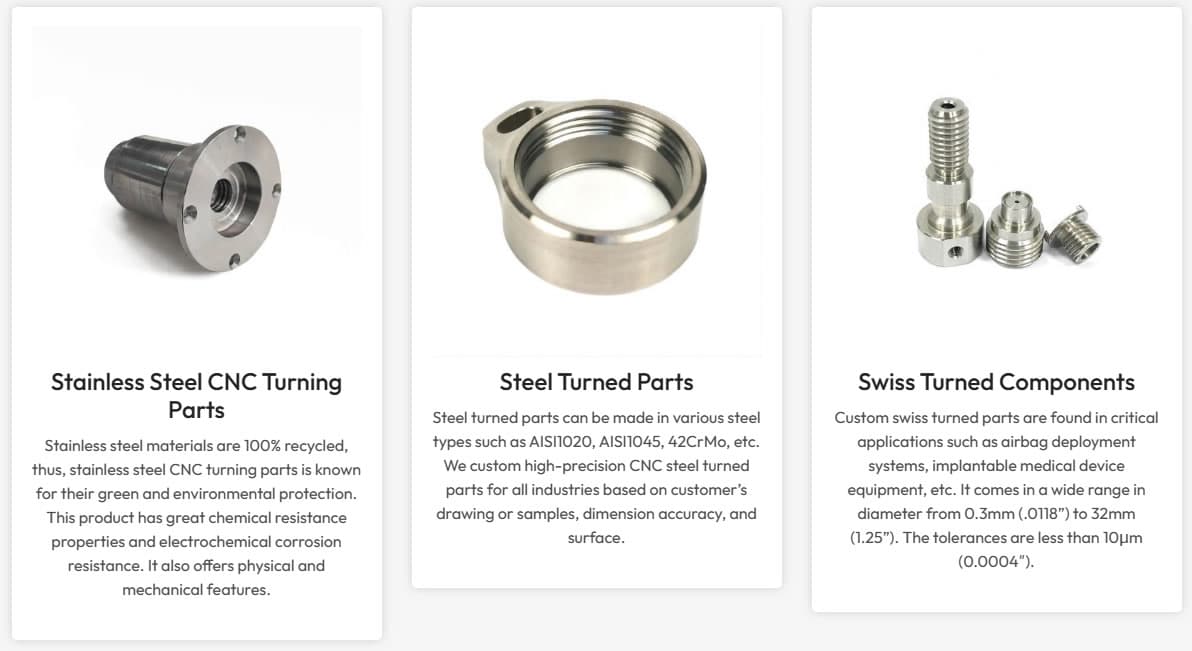

Similar to other CNC processes, CNC turning is also suitable for a broad range of materials. XTJ mostly use metal and alloys to produce CNC-turned parts. Among these materials include:

- Stainless steel

- Copper

- Steel

- Aluminum

- Bronze

- Brass

- Titanium

- Magnesium

Guaranteed that these materials are strong enough to handle pressure during the CNC turning process. We can also customize CNC turning parts material based on your requirements.

Custom Turning Parts Capabilities

XTJ has rich experience in providing custom turning parts services to different industries. We are well-equipped with a complete set of CNC turning machines and equipment. Our full capabilities include 1-axis, 2-axis, 3-axis, 4-axis, and 5-axis machining technology. Therefore, XTJ can surely produce CNC-turned parts ranging from simple to complex shapes.

Additionally, you can also ensure that XTJ can provide CNC-turned parts with tight tolerances up to +/-0.001mm. XTJ also guarantees custom CNC turned parts with varying thicknesses, dimensions, designs, and types based on your needs. Rest assured that XTJ produces custom CNC turned parts with high accuracy. Secondary operations such as surface treatments are also available to meet your requirements.

CNC Turning Parts Advantage

At XTJ, rest assured that all our CNC turned parts and components have high-quality.

Guaranteed Quality

XTJ implemented CNC turning quality control process. Thus, you can assure that all CNC turned parts and components are manufactured with fewer errors and defects. XTJ CNC turned parts are guaranteed with reliable quality.

Uses Wide Range of Materials

XTJ CNC turning is suitable for different kinds of materials. All materials are subjected to testing and complied certifications before production. Among the materials that we used includes:

- Aluminum

- Steel

- Stainless steel

- Brass

- Copper

- Titanium; and more

Comprehensive Quality Assurance

XTJ has expert quality control management that implements large-scale batch production inspections.

Thus, we can ensure that the produced CNC-turned parts meet your requirements. Aside from that, we are also certified by international standards such as ISO45001, ISO14001, ISO9001, IATF16949;2016, and more.

One-Stop Solution

XTJ offers a one-stop solution to your CNC turning parts services needs. We use advanced CNC turning machines that allow us to produce parts with precise cuts, accuracy, and high performance.

Aside from that, we also offer CNC turning services along with other CNC processes such as milling, drilling, machining, secondary operations, and more.

Custom CNC Turning Parts

At XTJ, we provide custom CNC turning parts to meet all your requirements. From materials, designs, thicknesses, to surface treatments, we can manufacture based on your specifications.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.