CNC Milling Component

XTJ offers a reliable CNC milling for producing components with simple and complex shapes.

We handle CNC milling with our in-house CNC machining and advanced equipment.

Custom CNC milling parts are also available to meet different industry requirements.

One-Stop CNC Milling Component Solution

Through our 3-, 4-, and 5-axis CNC milling centers and full CNC machining capabilities,XTJ can surely produce high-quality CNC parts.

All parts produced by CNC milling are widely used for automotive, home appliances, electronics, and more.

With our advanced CNC milling capabilities, we can manufacture parts with different shapes using materials such as aluminum, steel, stainless steel, copper, bronze, and more.

XTJ offers custom and cost-effective solutions for your needs.

XTJ can handle full production, prototype, or single-part production. You can contact us for customized solutions.

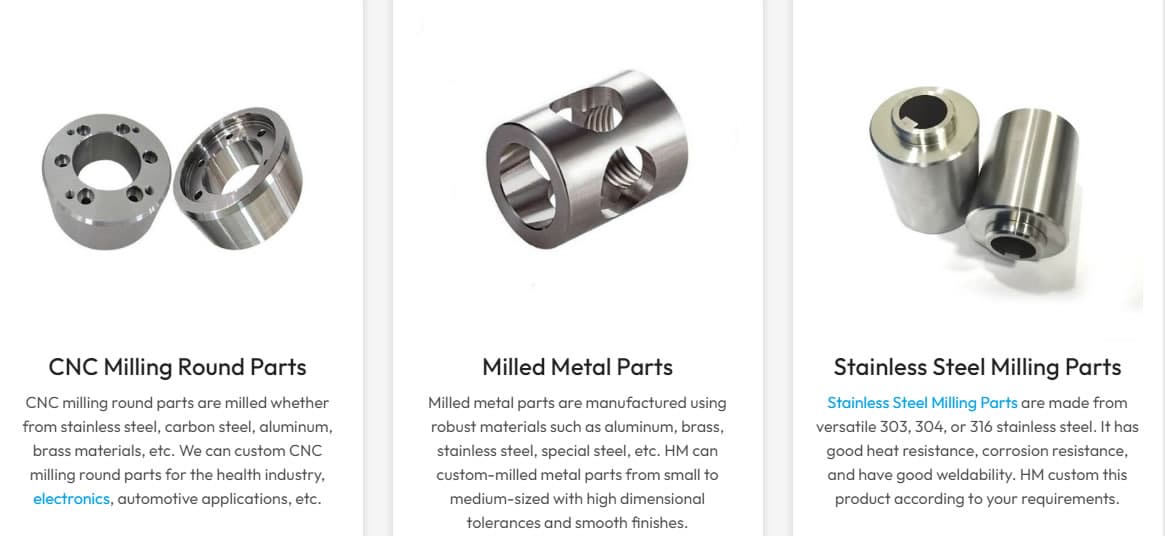

CNC Milling Components List

CNC Milling Component Material

CNC milling parts are typically used for a wide range of materials that can hold their shape when milled. Commonly, XTJ uses metal materials such as:

- Aluminum

- Steel/steel alloys

- Brass/bronze

- Zinc

- Copper

- Plastic

Advantages of CNC Milling

CNC milling parts comes with a lot of advantages such as:

- Suitable for complex shape parts. CNC milling machines can work with different angles. Thus, making it possible to cut and create CNC parts with complex geometries. CNC milling is also ideal for creating CNC parts with irregular shapes.

- Cost Efficient. CNC milling uses special cutting tools that allow the production of CNC parts in just minutes. CNC milling offers an automated setup making it suitable for mass production.

- Wide range of finishes and material options. CNC milling is can be used for a broad range of materials such as aluminum, steel, stainless steel, and more. XTJ can also provide different surface finishes such as anodized, powder coating, and more to improve appearance and performance.

CNC Milling Parts for Different Application

CNC milling is widely used for creating high-volume CNC parts and prototypes. XTJ CNC milling parts can surely fit different projects and applications. XTJ offers CNC milled parts such as:

- CNC medical parts

- CNC milled adapters

- CNC automotive parts

- Metal valves

- Mold components

- Machine components

- CNC milled electronic parts

- Automotive prototypes; and more…

CNC Milling Capabilities

XTJ can provide all your custom CNC milled parts requirements. Our expert engineers assure to provide tight tolerance and excellent milling surface. we are well-equipped with different types of CNC milling equipment such as:

- 3-axis CNC mill. The spindle of the CNC mills can reach X, Y, and Z-axis because of its 3 axes.

- 4-axis CNC mill. It allows excellent ability and greater flexibility for creating more-complex CNC parts.

- 5-axis. XTJ is equipped with the most advanced 5-axis CNC mill. It doesn’t require lots of setups since it allows CNC parts to be manipulated in different positions.

Aside from that, XTJ offers custom CNC parts using our advanced CNC milling process. Besides CNC milling, XTJ also offers other CNC services such as wire EDM, turning, and more.

CNC Milling Component Surface Treatment

XTJ offers a wide range of surface treatments to all CNC milled components. Here are surface treatments available for CNC milling.

Powder-Coated

This surface treatment process uses polymer paint applied under heat and electrostatically. It provides the CNC components with strength, corrosion resistance, and wear resistance.

Bead Blasted

During bead blasting treatment, a high-pressure glass bead is used for removing component tool marks. It can provide a matte or satin finish.

Anodized Type II

Type II anodized finishes are available in different colors. It provides more wear resistance and corrosion resistance to CNC machined components.

Anodized Hardcoat (Type III)

It is available in a colored or clear finish. It uses a thicker anodic oxide layer than an anodized type II. It also enhanced the CNC machined component’s wear and corrosion resistance.

As-Machined

After being machined, the component will not undergo any further finishing. Thus, resulting in a rough surface finish.

Aside from that, XTJ also offers other surface treatments such as brushed, smooth, electroplating, and more. We offer custom surface treatments based on your requirements.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.