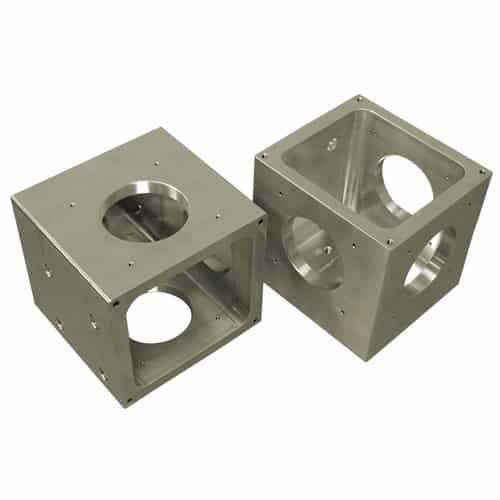

Surface treatment: Clear anodized

Corrosion resistance: Clear anodizing enhances the natural corrosion resistance of aluminum, making the parts suitable for various environments.

Lightweight: Aluminum is a lightweight metal, and the clear anodized layer adds minimal weight, making these parts ideal for applications where weight reduction is important.

Aesthetics: The clear anodized layer offers a clean and attractive appearance, sometimes with a slightly reflective finish. This can be beneficial for parts that are visible in the final product.

Electrical conductivity: While the anodizing process creates an oxide layer, clear anodized aluminum remains a relatively good conductor of electricity compared to other anodized finishes that use dyes or thicker oxide layers. This can be a benefit for some applications.

What Are Some Things to Consider When Choosing a Clear Anodized CNC Machined Aluminum Part?

The complexity of the design: CNC machining can create intricate shapes, but very complex designs might increase production costs.

The required strength and weight limitations: Consider the mechanical loads the part will experience and choose an aluminum alloy with appropriate strength.

The tolerance requirements: CNC machining offers high precision, but tighter tolerances may come at an increased cost.

The desired surface finish: While clear anodizing provides a good finish, other anodizing colors or coatings might be available depending on the application.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.