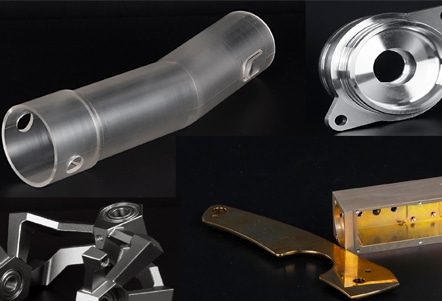

CNC Machining Services

CNC machining is suitable for plastic and metal parts and can be used to make from one single prototype to up to 50000 parts.

A wide variety of materials can be machined, including mild and stainless steel, aluminum, magnesium, zinc, brass and many plastics.

We also offer the production of precision-machined components. Our precision engineering department offers milling, turning, CNC engineering, surface

grinding, wire erosion, EDM spark erosion and more. All of your projects will be discussed carefully and checked before production starts. During and

after production the parts will be 100% inspected and we can provide original certificates for all materials used in the project as well.

parts, XTJ is the best place to go. Contact us today to get your manufacturing solution and details.

See why our cusomers love us

Our Advantages of CNC Machining

There are many CNC machining service providers to choose from. Here are the top 3 reasons you should choose us:

- Experience

Due to their extensive experience and knowledge gained through previous projects, our engineers can handle complex and precise parts across several industries with ease.

2. Advanced Equipment

A total of 120 pieces of 3 axis, 4 axis, and 5 axis CNC lathes are available at Xin Tian Jian, including the Germany DMG and GROB, as well as a number of 5 Axis Gantry CNC machines from APEC Taiwan

3. Fast Turnaround

On average we return quotes within 24 hours, parts ship within 3 days or less, and we have over 99% on-time delivery and quality rate.

CNC Machining Tolerances

Our wide array of CNC machines allows us to manufacture stand–tolerance CNC machined parts at a competitive price, as well as high-precision machined parts for the high-end market. When working with XTJ, we guarantee all parts will be manufactured according to your specifications.

Precision Machining

In addition to CNC parts with standard tolerances such as ISO 2768-mk or ISO 2768-mf, XTJ also offers high-precision CNC machined parts. With our high-precision milling and turning machines, we are able to meet very tight tolerances for prototype machining and production.

Having been in the manufacturing industry for over 10 years, we have discovered a simple formula for producing precision parts

Precision machines + Precision heart = precision parts.

XTJ has a wide range of CNC machines and experienced engineers who never compromise on tolerances or part quality.

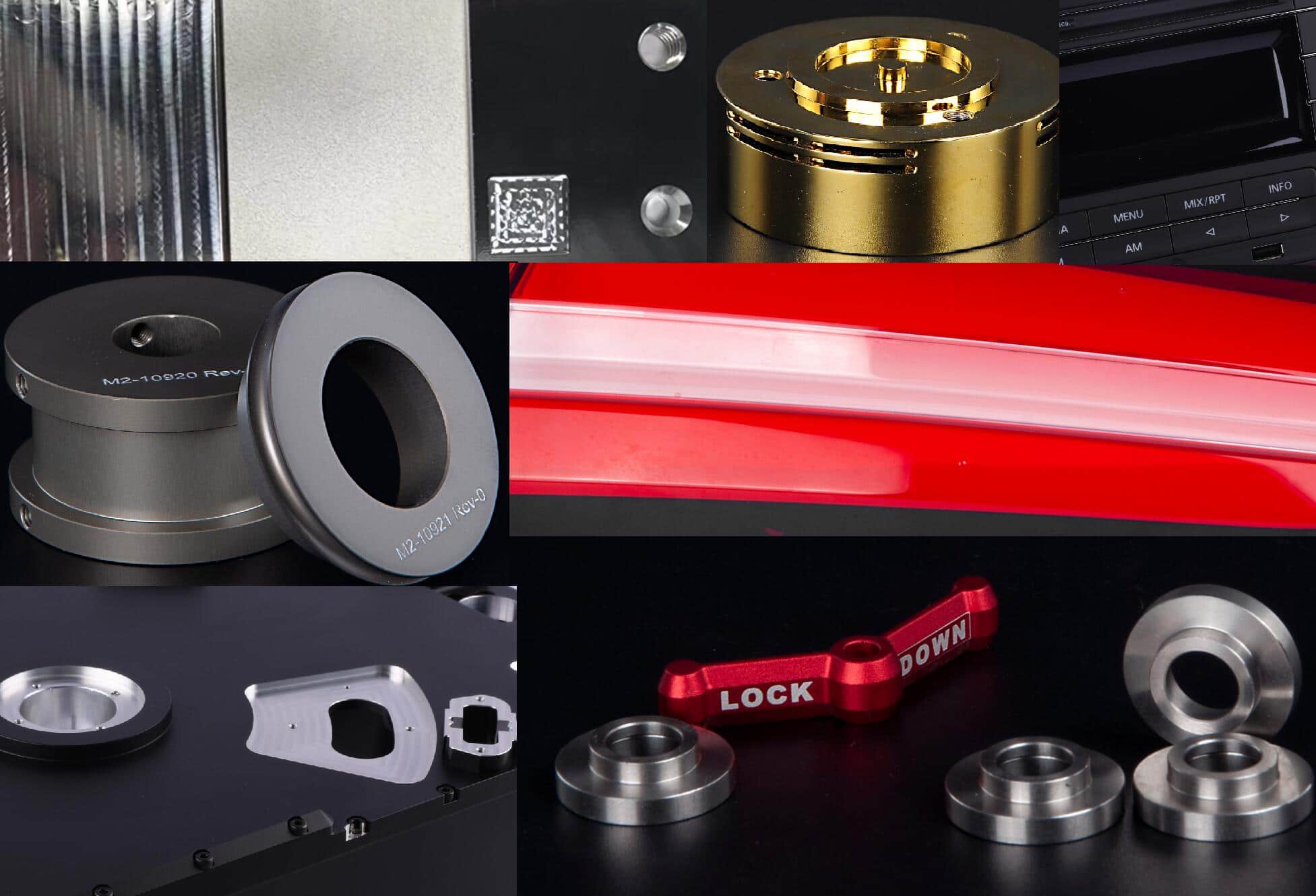

CNC Machining Materials & Finishes

If you are considering CNC machining your parts, it is important to know what materials and surface treatments can be applied to your CNC machined parts. XTJ, based in China, is not just a CNC manufacturing company. Thanks to our surface finishing partners, we can also apply all kinds of finishes to CNC prototype parts and production parts. Do you need customized CNC parts with a high-quality appearance? XTJ is here to help.

Overview: What’s CNC Machining?

What is CNC machining?

CNC machining is a manufacturing technique for removing material. It uses sharp cutting tools that come in a variety of shapes and sizes and are precisely controlled by a computer. CNC stands for Computer Numerical Control.

How CNC machining works

CNC machining begins with a computer on which designers prepare a part using CAD (computer-aided design) software. This digital part is then converted into a format that can be recognized by a CNC machine.

The instructions are sent to the CNC machine in the form of “G-code,” after which the machine can begin cutting.

Most CNC machines have a “work table” and a workpiece holder to hold a block of material – called a “workpiece” – in position. Depending on the type of machine, the work table may or may not move.

When machining begins, the cutting tool comes into contact with the workpiece and cuts away layers of material. The tool and/or workpiece is moved and/or rotated quickly according to the instructions of the G-code so that the cuts are made in exactly the right places until the part is finished.

Different types of CNC machine

CNC machines include CNC mills, CNC lathes (or lathes), CNC routers, and electrical discharge machines (EDM).

CNC mills have rotating cutting tools that are moved to different areas of the workpiece to make cuts. CNC lathes work in reverse, rotating the workpiece against a stationary cutting tool, and are used to produce cylindrical parts.

CNC mills are similar to CNC routers, but have less power and cannot cut the hardest materials. However, they can be faster than CNC mills.

EDM uses electrical discharges (sparks) instead of a sharp cutting tool to cut material. There is no physical contact between the tool and the workpiece.

CNC machines are often defined by the number of axes they have. More axes mean they can move the tool and/or workpiece a greater number of ways, providing greater cutting flexibility and the ability to produce more complex parts in less time.

CNC Materials

Plastics: ABS, PC, ABS + PC, PP, PS, POM, PMMA ( acrylic ), PAGF30, PCGF30, Teflon, DHPE, HDPE, PPS, PEEK. Learn more about our plastic processing

Metal: aluminum, steel, stainless steel (17-4, Inconel 625 & 718), magnesium, titanium, zinc, brass, bronze, copper. Learn more about our metal machining

These are the most common materials for CNC prototypes and production parts. In addition, we can handle any type of machinable plastic and metal we can acquire on the market. Check more materials and surface options

CNC Finished

As-Machined: The most popular and cost efficient way for inner functional components. Fine and even tool path is also good for aspect parts.

Bead Blasted: The part is left with a matt appearance. Range of 120 to 320 beads allows us to create different roughness to the surface.

Anodized: Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and blue are most common—and is usually associated with low silicone element series of aluminum. Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

Powder Coat: This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic

CNC Machining FAQ

CNC machining is a fast, accurate and versatile solution for producing plastic and metal parts for end users in any quantity without having to invest in heavy tooling or expensive setups. No matter how simple or complex the parts.

There’s a wide range of materials that can be used in CNC machining – you can use such as aluminum, steel, brass, copper, titanium, as well as rigid plastics. Reach out to learn more about the types of materials that could be used.

Xin Tian Jian is known as one of the best CNC machining companies in China in terms of quality, speed, and customer service. With high-quality CNC machines, we can easily achieve +/- 0.02mm of tolerance and can even get within +/- 0.01mm. But keep in mind that it can have an impact on the cost.