XTJ Quality Control Standard

XTJ Quality Control Standard

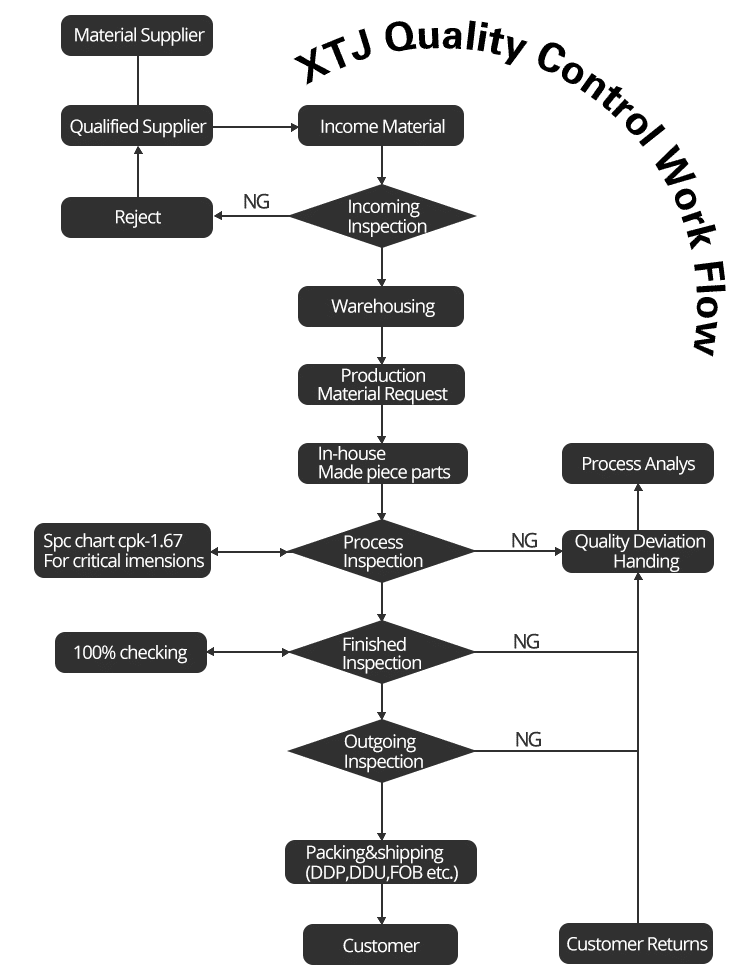

XTJ provide high-quality parts by excellent process control techniques and advanced equipment. Our quality management start from material identification, quality inspection to final products testing. We have advance inspection measuring and testing equipment to qualify all supplier raw materials, in order to guarantee our produced parts will satisfy all your exact specification requirement. Further more, we will monitor every project step for quality assurance:

Design review for all manufacturing quotation

Contract review upon receipt of products order

Raw materials inspection

First article and in-process inspection

Final inspection and testing with reports and certification

Visual Quality Standards

Quality You Can Rely On

XTJ machined parts are used in millions of devices and machines worldwide. Some components are used in very high tech applications like medical diagnostics,sensor,aircraft,and so on. As a professional precision machining manufacturer, we know nothing is more important than production quality. To ensure or even exceed the quality requirements of our customers, we have equipped with leading-edge inspection equipments and detailed quality control processes.

Select Perfect CNC material Raw material inspection equipment

In order to supply high quality parts for our customers, we perform plastic and metal testing for all raw materials. Our advanced inspection testing equipment will qualify all incoming materials for Positive Material Identification.

Bruker Alpha II FTIR Infrared Spectrometer

This is the newest equipment in our testing lab for material inspection. This tester use wide spectral band infrared radiation to verify plastic samples, its accuracy is higher than 97%. With application of this equipment, we can guarantee that our plastic material is complete conformance with your specific order.

PolyMax Analyzing Gun

In injection molding process, we need to select the right resin form thousands of available plastic kinds. PloyMax Analyzing Gun can help our technical team make the right choice in material selection step. With this device, a laser light is used to bounce off resin sample surface, read its unique signature of molecular vibration. Its own database of plastic types will soon identify test sample kind. This device make sure that we will offer your right material every time.

Optical Emission Spectrometer (OES)

This testing apparatus use optical spectrometer to read discharge plasma result, which is unique for every metal element once electrically charged by current. Then we can determine final metal composition finally. There are too many metal alloys and grades in market, it cannot be avoid that some similar metal materials may be mislabeled or fraudulent. Our Positive Material Identification for all raw metal material will guarantee that you will receive exactly what your order.

XRF Analyzer

X-Ray Fluorescence analysis in a non-destructive testing way, it use calibrated spectrometer to analyze different wavelength reflect by each element, then present element types and relative concentrations. Metal, plastic and ceramic will be exposed to low level X-ray or gamma radiation in testing process.

Final part inspection equipment

Our Final inspection department is crucial for our ISO certified manufacturing, we can perform quality control in final parts inspection by our inspection equipment, and guarantee our parts production match all your design specifications.

Zeiss Comet L3D 2 Optical Scanner

This device use interchangeable lenses and sensors to scan five million data points of final parts, in order to capturing and computing precision 3 dimension data, and then check parts conformity, identify parts errors. As a portable device, it will make our final inspection work effective.

SmartScope ZIP Lite 300

It is an no-contact optical measuring device, use high intensity white LED light for parts 2 dimension measuring. Its high precision consist of high-precision mechanical bearing, DV stepper motors and measure mind software. We can use quick program to automatic similar shape measuring of final parts.

Coordinate Measuring Machine

CMM can collect final parts points data, and then use these database to measure parts with complex shape. With its huge data in three dimension for parameter of various shape, we can inspect our final parts with acceptable accuracy and repeatability.

Surfometer

Our surfometer can check final part surface roughness, we use this device to guarantee specific surface finishes as custom requirement. Its portable advantage make our checking process more convenient.

X-Rite Spectrophotometer

We use this device to analyse final parts color and verify precise color sample. With source light reflection of part surface, this device can determine precise numerical value of parts color with color standard comparison. We can send all these information for final confirmation, in addition, we also use this device to monitor and control manufacturing process for your complete satisfaction.

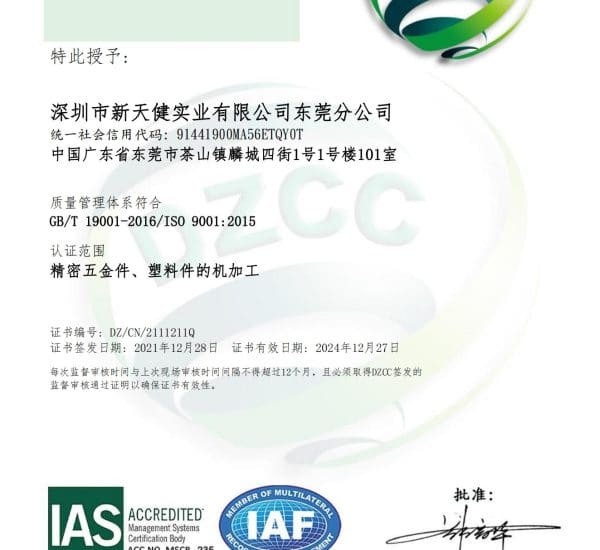

ISO Certified Manufacturer

Our ISO 9001:2015 quality system is not only a operation standard for us, but also our core business functions in every aspects. We start form assistance of custom product design to final parts assemble and shipment. Our specialized manufacturing with quality control guarantee excellent service for customers in worldwide.

Mold manufacturing quality control

As your loyal supplier, we have strict manufacturing quality control in CNC machining, Injection molding, 3D printing and Die casting. In order to ensure these control process implement in place, we schedule following steps:

Part Design Checking

Mold Design Control

Raw material inspection

Visual inspection

FAI – First Article Inspection

PPAP – Production Part Approval Process

Mold Steel Hardness Inspection

Mold Electrodes Inspection

Mold Core and Cavity Steel Dimension Inspection

Mold Pre-Assembly Inspection

Mold Trial Report and Samples Inspection

Pre-Shipment Final Inspection

Export Product Package Inspection