The simple answer is that making a successful injection mould tool is a hugely complex undertaking that require a lot of thought, planning, expertise and labour. The higher the complexity, the more expensive the cost of your mould will be. In this section, we break down the main factors that make up and impact the cost of an injection mould tool.

1. Material Cost

Injection moulds are subject to thousands of pounds of pressure every cycle and high levels of heat. As such, the moulds need to be made from strong, durable materials that can withstand the harsh operating conditions without deforming. These moulds are often made from different grades of steel or aluminium.

the cost of injection mould tools in steel and aluminium

The choice of material for the mould will likely depend on the number of parts to be produced. The more parts to be produced, the better and more expensive grade of steel should be used.

2. Mould Construction

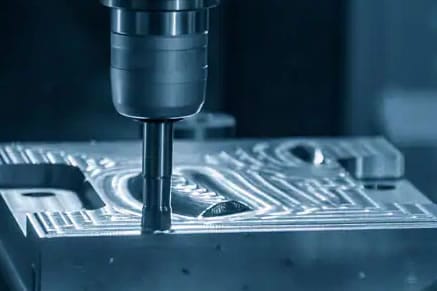

Various complex elements are made and assembled together using a range of manual and automated processes to form the injection mould or mould tool to guarantee a reliable and repeatable injection moulding process. These components are shaped to tight tolerances using specialist machinery, including CNC machining and EDM (electrical discharge machining), which significantly adds to the cost.

3. Mould Complexity & Aesthetics

Several mould design decisions, such as side pull actions, number of cavities, texturing, multi-material shots, tight tolerances, engraving, undercut features, inserts, etc. will also significantly add to tooling costs. While costly, these design decisions may be a necessity or beneficial in the later stages of the process.

4. Labour Costs

Don’t forget to factor in labour costs. Designing, creating and assembling injection moulds is a labour-intensive and complex process that takes time and skill to do correctly. Injection mould builders and designers are highly trained specialists that don’t come cheap. If you cheap out on this, you might have to pay for the costs later on.

Is injection moulding actually expensive?

Once the tooling process is complete, it’s important to note that injection moulding is an almost entirely automated process, compared to other forms of manufacturing methods. Hence allowing for an efficient and economical method of producing higher volumes of plastic parts — making the expensive initial injection mould cost highly worthwhile.

In fact, plastic injection moulding is often found to be one of the cheapest manufacturing processes when taking into consideration the total manufacturing cost for projects involving higher volumes.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.