Iphone Case,Cellphone Case CNC machining

| Information | |

|---|---|

| Industry | Consumer Electronics,Cellphone |

| Product | Iphone Case |

| Challenges | Consistent surface contours and aesthetics, Anodizing with different colors |

| Technology | CNC milling |

| Material | AL6063 |

| Surface finish | Anodizing |

| Quantity | 100 Sets |

| Lead Time | 50 Business days |

About Customer: Jason Lee, Phone Case Trader in Huaqiang Bei,Shenzhen City

Jason Lee is a trader business man in China from shenzhen. He is at shenzhen,he as a small shop at Hua qiang Bei,

He sell the Cellphone Case at Ebay,amazon and shopee and his own e-commerce website.

He can design the Case by CAD Software.

How to Design the case for Cellphne,for example Iphone 15 or Iphone 14?

Whether a CNC user plans on manufacturing a phone case using a 3D Printer or carving it out from a solid material block, it is an uncomplicated project. Furthermore, these cases serve as exceptional holiday presents.

The key is accounting for the dimensions of the phone itself. One can measure the phone, or, in the case of Apple at least, we can obtain the official blueprints they provide for organizations that want to make cases and other accessories. Apple has a page all set up for developers to access. On that page you will find a link to a document called “Case Design Guidelines for Apple Devices.” That’s where you’ll find the dimensioned drawings for all of Apple’s phones and portable devices like iPods and iPads.

Once you get your hands on the document describing your device’s dimensions, you’ll need to put together a CAD drawing that captures the outline of the phone:

iPhone 15 Outline

Using your CAD program, generate the outline of your phone…

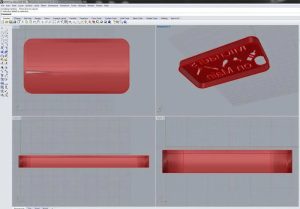

I’m using Rhino3D for this project, but most any CAD program capable of 3D modelling can be used to follow along. I simply created a rectangle with the overall height and width of the phone (leaving out the buttons that protrude). I then filleted the corners to the appropriate radius. That yields the yellow outline–very easy!

The next question you’ll have to decide is how thick to make your case. For this project, I wanted a case that would not add bulk to the already svelte iPhone, and that would make it easy to operate the phone’s controls through openings in the case. So, I chose to make the case 1.5mm thick. To do that, I simply offset the inner outline by 1.5mm. All decent CAD software will have the ability to offset a line like that.

Now I have the basic outline of the case. Time to start converting it into a 3D model. In Rhino, I simply extrude that outline to the some height. This creates the sides of the case:

CaseSides

Phone case sides…

Then I extrude the outer line in the opposite direction for 1.5mm to create the bottom of the case:

CaseBottom

Case with bottom added…

Now I have a solid model of a case. Granted, it’s generic, and I haven’t added the cutouts to access buttons, expose the camera, and so on, but it’s a start that was easily created. Go ahead and add those cutouts and you’ll have a generic case template suitable for your phone. For now, I’ll leave adding all the cutouts to the reader, but let’s have some fun personalizing this case.

You’ll notice I drew the case face down. That’s because the personalization I want to do goes on the back of the case, and I wanted to make that part easy on myself. What I decided on was to create a custom logo’d case for a close friend who owns a local restuarant. I’ve been a Guest Chef there a number of times and I wanted to give him something fun from my world of CNC. There are a variety of things you could do to customize a case like this, but I decided to keep it simple. My task was to create cutouts in the case that create a logo of his restaurant. The finished 3D model looks like this:

MichaelsCase

Finished 3D Model of a custom phone case…

As you can see, this case is an exercise in making a cutout on the back of the case that looks like line art. The first task in doing that is to create the line art:

TextOutline

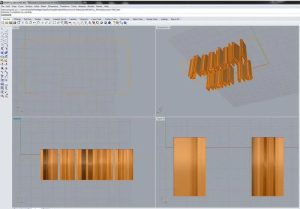

I started with a text outline. I positioned it above the bottom of the case in the Z dimension, and then I extruded it downward:

ExtrudedText

Extruding the text…

Using a similar process, I created the icons of wine bottle, glass, knife, fork, and fish:

CookieCutter

The extruded cookie cutter for the design…

Think of these extrusions as a “Cookie Cutter” that can be used to cut the design out of the back of the case. You’ll notice I added a shape for the camera cutout to make sure it wouldn’t interfere with my design.

Once I had the Cookie Cutter, I used Rhino’s Boolean Difference operation on the solids to cut the design out of the back of the case:

CookieCutter2

Subtract the Cookie Cutter from the case using a Boolean Difference…

That’s pretty much all there is to preparing a 3D model of your case suitable for 3D Printing or other CNC Work. I think I spent about an hour in total on the design work. It’s a very easy project and well suited to a beginner. Give it a try.

When we get done building our Rostock Max v2 3D Printer, this will be one of the early things we’ll want to print on it. I’ll be sure to share the results when that’s done.

This was a very simple case and I have no doubt you’ve already come up with lots of ideas to embellish your own custom phone case. Send us pictures if you make or design a case so we can share with the readers.

CNC machining For The Phone Case

CNC machining is a crucial part of case design and manufacturing. Smartphone cases require accurate dimensions for a nice snug fit. However, the smartphone will slide out of the case if the dimensions are too loose. While if the dimensions are too tight, you won’t be able to fit the phone inside it.

Templates

Phone manufacturers often ship out dummy units made out of solid aluminum to case manufacturers. These units have the same size and shape as the final product and are meant to be used as case templates.

Phone Cases

Phone cases are often manufactured using the injection molding process. It is an insanely cheap method of producing large volumes of the same product. But CNC is still predominant in the high-end case market. Leather cases are precision cut by CNC lasers and shaped to the body of a smartphone.

Additionally, some niche companies are offering wooded cases machined out of real natural wood.

CNC machining

Touch-sensitive glass is now the norm for phone screens. As smartphones have grown in popularity, the demand for thinner and more precise glass tops has also increased. The glass top of a smartphone is a super-thin layer, coming in at under 3mm.

The problem with machining glass is precision, but about control. Glass is a brittle material, and when put in such a thin form factor, the risk of cracks increases exponentially. CNC machines slowly and carefully cut and shape the touch-sensitive glass with unparalleled precision.

Recently smartphone manufacturers have opted to use punch-hole cutouts or notched displays for their smartphones. Require additional precision, accuracy, and care while machining. An added challenge to glass machining is reducing the chances of scratches. Even if the glass doesn’t crack, scratches can render the entire product useless.

Customizations

CNC machining is at the very core of custom designs. And what better product to customize than your smartphone. Customizations for smartphones are typically reserved for phone backs.

Phone backs are flat metal, plastic, or glass sheets attached to the frame. The simplest method of customizing a phone back is engraving and etching. Manufacturers often use this process to add their logos or phone details on the back of the phone. You can use the same technique to engrave personal messages on phone backs for gifting purposes.

Another means of customization is a complete overhaul of the back design. You can add new design elements and cutouts for limited edition backplates for your smartphone.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Celllphone Case from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.