CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following:

Improves accuracy of the machining process

Increases safety during machining

Helps complete tasks faster and in details

Reduces changeover time

Boosts production volume

Enables flexibility in manufacturing

On every CNC machine, there is an electronic measuring system on each controlled axis. This helps to identify the positioning of slides on the slideway. They also play an important role in orienting the spindle table, helping to measure the real spindle speed. There are also CNC controls for simple applications for turning the machining centers. Other features include automated lubrication systems, boring heads, transitivity, spindle options, and automated tool length setters.

CNC machining is a versatile and cost-effective manufacturing process. This process is compatible with a huge range of materials. As such, CNC machining helps across a diverse array of industries for a variety of applications. Manufacturers and machinists use this process in various ways. This includes direct manufacturing process, indirect manufacturing process, or in conjunction with other processes.

As with any manufacturing process, the unique advantages of CNC machining inform the kind of applications for which it can be used. However, the benefits of CNC are desirable in virtually any industry. They are suitable for many parts and products. Since CNC machines can process almost any type of material, their applications are near limitless.

From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Let’s get straight to it!

Table of Contents

Industries That Use CNC Machining

CNC machining prototype productions are not tied to any single sector. People use it virtually everywhere. It helps to create everything from aircraft parts to surgical tools. We can, therefore, characterize the applications of CNC machining in different industries. The following industries gain from CNC machining purpose:

Aerospace Industry

The aerospace industry has a long-shared history with CNC machining. The machining of metal aircraft components occurs at the highest level of precision. This is highly essential for safety-critical applications. Also, the range of engineering metals compatible with CNC provides aerospace engineers with plenty of options.

applications of cnc machining in the aerospace industry

The applications of CNC machining in the aerospace industry are wide and reliable. Some of the machinable aerospace components include engine mounts, fuel flow components, landing gear components, and fuel access panels.

Automotive Industry

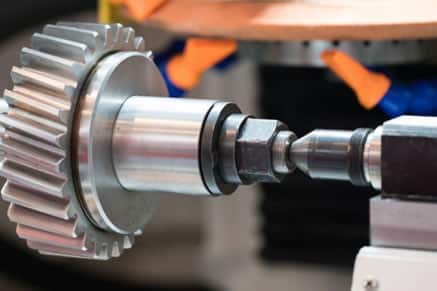

The automotive industry regularly enjoys the uses of CNC milling machine for both prototyping and production. Extruded metal can be machined into cylinder blocks, gearboxes, valves, axels, and various other components. On the other hand, CNC machines plastics into components like dashboard panels and gas gauges.

applications of cnc machining in the automotive industry

CNC machining in the automotive industry is also useful for creating one-off custom parts. The creation of various replacement parts is also possible with CNC. This is because the turnaround times are fast, and there is no minimum required part quantity.

Consumer Electronics

CNC machining also helps in the prototyping and production of consumer electronics. These electronics include laptops, smartphones, and many others. The chassis of an Apple MacBook, for example, comes from the CNC machining of extruded aluminum and then anodized.

In the electronics industry, CNC machining helps to create PCBs, housings, jigs, fixtures, and other components.

Defense Industry

The military sector frequently turns to CNC machining for the prototyping of rugged and reliable parts. The intention of the machining is to allow the parts to withstand wear and tear with minimal upkeep.

Many of these parts overlap with other industries such as aerospace and electronics. The ability of CNC machines to provide on-demand replacement parts and upgraded components are particularly useful in this industry. Therefore, it works well for parts that demand constant innovation and security.

Healthcare Sector

CNC machining offers its use on various medically safe materials. Since the process is suited to one-off custom parts, it has many applications in the medical industry. The tight tolerances afforded by CNC machining are essential to the high performance of machined medical components.

cnc machining uses in healthcare sector

CNC machinable medical parts include surgical instruments, electronic enclosures, orthotics, and implants.

Oil & Gas Industry

Another industry that requires tight tolerances for the safety-critical application of CNC lathe is the oil and gas industry. This sector leverage the uses of CNC milling machine for precise, reliable parts such as pistons, cylinders, rods, pins, and valves.

These parts are often used in pipelines or refineries. They may be required in smaller quantities to fit specific quantities. The oil and gas industry often requires corrosion-resistant machinable metals like Aluminum 5052.

Manufacturing Possibilities of CNC Machining

Another way by which we can categorize CNC machining application of numerical control is by the manufacturing possibilities and uses. CNC machining is very useful in the following areas:

CNC machines have fast turnarounds because they are highly autonomous. Once a digital design is complete, machinists can send them to the CNC machine and fabricate them in a short space of time. This makes CNC machining highly useful for prototype machining. The application of CNC lathe is robust, regardless of the method used for the machining of the final component.

cnc machining

Machined prototypes come at very high standards. They usually more closely resemble the end-use parts.

Production

CNC machining is precise enough to create high-quality components for the end-use application of numerical control. The material versatility of this process allows for the fabrication of a wide variety of parts. Overall, CNC machining is a cost-effective manufacturing process for many projects. Regardless of size or scope, several industries use the manufacturing process to create usable final parts.

Tooling

In addition to being an excellent direct manufacturing process, CNC machining is an indirect manufacturing process to aid processes like injection molding. It helps to machine various steels and robust aluminum. The machined parts such as metal molds can be filled with other materials to create products in large quantities.

Hybrid Manufacturing

CNC machining does not have to be used independently of another manufacturing process. Combining it with other processes like 3D printing or metal casting can lead to superior parts and products.

hybrid manufacturing applications of cnc machining

It is possible, for example, to CNC machine features such as holes and threads in a printed or cast part.

Electrical Discharge Machining (EDM)

CNC automation enables electrical discharge machining (EDM) in two ways. It allows vertical EDM requiring electrodes with a similar shape and size as the cavity to be carved out. The other type of EDM is the Wire EDM. This type helps to create the punch and die combinations for different die sets used in metal and plastic fabrication.

Conclusion

There is are several applications of CNC machining in various industries. Whatever industry you’re in, there will definitely be some type of CNC machining practice that will suit your needs. At RapidDirect, we offer a wide range of quality, high performance, and easy to use CNC machining processes. Our engineers have robust training and a comprehensive understanding of these processes. You can be sure of getting the best services at competitive prices.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.