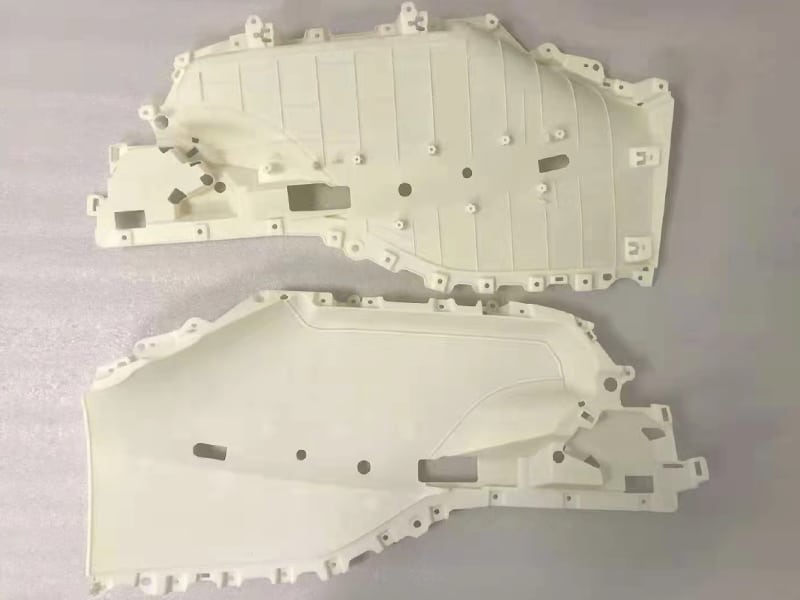

Processing methods: 3D Printing + CNC plastic processing

Materials Used: ABS

Minimum Tolerance: 0.01mm

Manufacturing Cycle: 5 Days

Product Dimension: 1800*600mm*500mm

Post-Processing: Ash Spray + Sanding + Oil Spray

Table of Contents

XTJ Prototyping Advantages:

1. Relying on advanced equipment and unique process design, using advanced materials, the produced hand plate has clear lines and higher reliability.

2. Xin Tian Jian Precision Mfg has been focusing on the prototype industry for 17 years, with rich experience and a large number of skillful technicians. Over the years, 96% of our customers are fully satisfied.

3. Cnc processing and complex mold processing utilize imported advanced equipment and technology, and the highest precision tolerance can reach ±0.01mm.

Processes that can be carried out on automotive prototypes:

1. CNC plastic processing

2. Dust spray

3. Polish

4. Fuel injection

5. Assembly

Technical characteristics of the prototype model:

1. Automatic quotation platform, one click to get a quotation.

2. CNC machining, 3D printing, complex mold, sheet metal, rapid mold.

3. Personalized customization and small-batch production.

4. Support multiple 3d drawing file formats: IGS / x-t / PRT / STP / STL are all available.

5. The size range of the prototype model is large, as small as a few centimeters, as large as a few meters.

Advantages of XTJ Precision Mfg prototyping making:

1. One-stop service from design to production to after-sales service.

2. Obtained a number of international certifications and quality assurance for many years.

3. Advanced equipment, perfect prototype production technology, can be delivered within as less as 48 hours

4. Many of the world’s top 500 preferred prototype service providers, professional and efficient.