Table of Contents

What is CNC Controls?

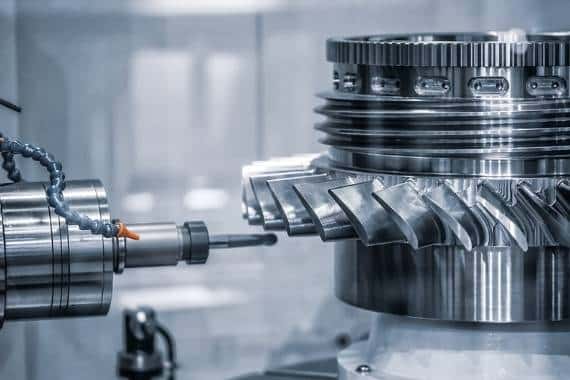

This article covers the types of CNC machine control software available. CNC machining is the computer-controlled process of forming metal into fabricated components. CNC actually stands for “computer numerical control” and is aptly named—the computer directs the cutting tool based on a series of numeric codes that can be altered using computer software.

CNC machining changed the metal fabrication industry by enabling easier production of 3-D structures and reducing the level of human involvement in metal forming. Since the introduction of CNC machining, improvements in quality and consistency have increased.

Types of CNC Machine Control Software

When multiple CNC machines manufacture a part that requires multiple operations, designers refer to that group of machines as a “cell.” Today, CNC machines are typically automatons, as they have the ability to perform without human assistance. The software packages that control these CNC machines are CAM (Computer-aided Manufacturing) programs.

CNC Machining Software Origins

NC (Numerically Controlled) machining preceded CNC machining—these earlier machines featured unalterable, fixed hard-wired operating parameters. NC machines were controlled by “G-Codes,” which are punched-tape applications fed into the machine’s computer.

CAM Software

Specific files created by CAM software control today’s CNC machines. CAM software reduces production time by eliminating the need to produce a drafted paper drawing of the desired manufactured component.

With CAM software controlling the CNC machine, the machine is capable of producing a high volume of parts without human assistance. CNC machines controlled by CAM software also feature lasers capable of detecting even slight imperfections in the finalized product. When the laser detects a problem, the computer automatically phones the operator’s cell phone and notifies him of the situation.

CAD Software

CAD (Computer-Aided Design) software is the program used to design the product that the CAM software program will eventually produce. Most of today’s CAD programs feature 2D vector base drafting systems or 3D solid and surface modelers.

CAD software provides designers with the freedom to create their product on the computer screen and save it for later editing and printing, which cuts down on design and production time. Other capabilities of CAD software include:

3D parametric feature-based modeling

Solid modeling

Freeform surface modelling

Reuse of design components

Wireframe geometry creation

Automated design of assemblies

Calculation of mass properties of assemblies and parts

Aid visualization with shading and rotating

Bi-directional parametric association

Cable routing

Electrical component packaging

Inclusion of programming code in a model to relate and control the desired attributes of the model

Programmable design optimization

Sophisticated visual analysis routines

Verification of designs against design rules and specifications

Automatic generation of standard design components

Simulation of designs without building a physical prototype

Maintenance of libraries of parts and assemblies

Output of design data directly to manufacturing facilities

Output directly to a Rapid Prototyping or Rapid Manufacture Machine for industrial prototypes

CAE Software

CAE (Computer-Aided Engineering) tools assist engineers in the analysis, design, simulation, planning, manufacture, diagnosis, and repair of machining activities. CAE tools manage tasks in three phases: Pre-Processing, Analysis and Post-Processing. The areas addressed by CAE applications include:

Stress analysis on components and assemblies using Finite Element Analysis

Thermal and fluid flow analysis

Kinematics

Mechanical event simulation (MES)

Analysis for process simulation for operations such as casting, die press forming and molding

Optimization of the process or product

CAD/CAE/CAM Software

Some software companies have merged all three aspects of CNC controlling applications into one, manageable software package, labeled CAD/CAE/CAM. These software programs handle the entire fabrication process: the original design created in CAD, the analysis performed by the CAE, and the final manufacturing as controlled by CAM software.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.