CNC machining in Copper

Excellent thermal and electrical conductivity Copper offers excellent thermal and electrical conductivity, it’s often used for busbars, wire connectors, and other electrical applications. Copper has a glossy reddish-orange appearance.

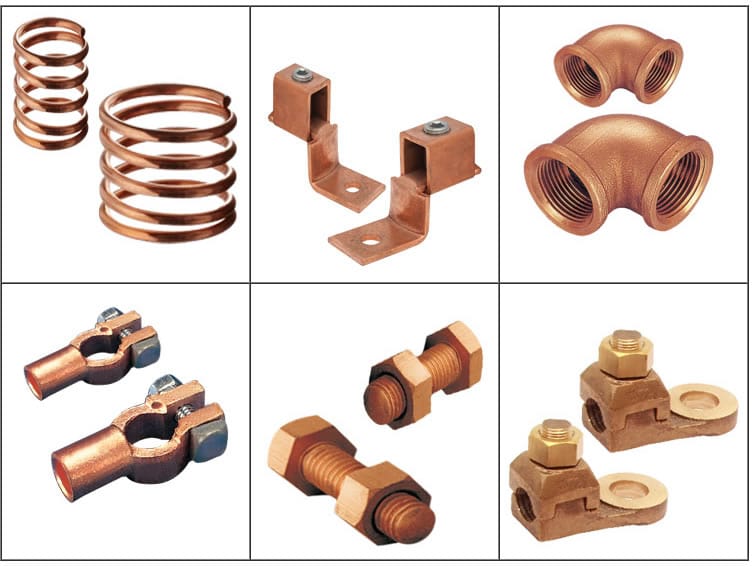

Copper Parts and Components is the XTJ engaged in manufacturing and export of high quality non-ferrous metal castings, components and wiring accessories. We have been producing inexpensive but precision metal components at our three manufacturing sites since more than 3 decades. We produce all types of Copper Parts, Copper Clamps, Copper Washers, Copper Electrical Terminals, Brass Hose Barbs, Hose Fittings Couplings, Brass Turned Parts, CNC Turned Parts, Copper Machined Parts, Brass Inserts, Plastic Moulding Inserts, CNC components, Brass Nuts, Copper Lay in Lugs, Copper Forgings, Copper Pressed Parts, Copper Terminal Blocks, Copper Cable lugs etc.

Copper milling

Copper is an incredibly versatile metal, making it an optimal choice for producing CNC machined custom parts. The alloy has several useful properties alongside its versatility—this is why companies working in industries such as electrical, construction, transport and consumer goods use it for many applications. CNC machined copper parts begin as raw pieces of metal that are cut down bit by bit to create a desired shape or object. This process is done most accurately with a CNC (Computerized Numerical Control) machine which can produce almost any three-dimensional object designed via CAD (computer-aided design) software.

Copper parts

XTJ offers a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics. We operate almost every kind of CNC mill and turning center, and are able to machine whatever you need, from simple, “as-machined” workholdings to complex, organic geometries with tight tolerances. When creating Copper parts with us, you can apply up to 7 different post-processing/surface finishing options including bead blasting, powder coating, smooth machining and polishing.

Copper CNC machining services

XTJ offers a state-of-the-art copper CNC machining service, guaranteeing consistent quality and fast turnaround times. We have over 1,600 milling and turning machines at our disposal, which means capacity is virtually always available and prices are always competitive. Our manufacturers allows us to fulfil orders with a low volume of CNC machined copper parts as well as more complex copper machining. We can fulfil complex orders for prototypes and low volume production runs in a wide variety of post-processing and surface finish options. Work with us to access our vast CNC copper machining supply chain today.

How to CNC mill copper?

To get CNC-machined copper parts from Protolabs Network, upload your CAD (.STL) files onto the platform and use the quote builder to get your parts into production.

How much does CNC machining copper cost?

The cost of CNC machining Copper depends on the complexity and size of the part and the type of Copper. These variables will affect the type of machine that is required, the time it takes to produce the part, and the cost of the raw material.

We use machine learning algorithms to calculate the exact cost of any machinable part directly from a CAD file, based on millions of CNC machining orders we’ve previously processed.