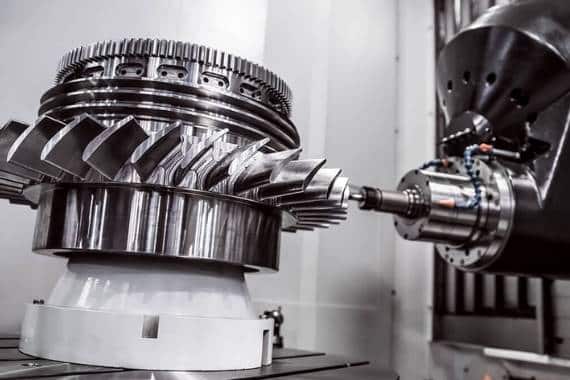

XTJ , Professional and Well-Experienced in CNC Machining Parts

As a professional manufacturer, we are fully equipped with over 100 sets of high-precision CNC machines. XTJ assures you a superior in-house CNC machining capacity to ensure high-quality parts.

Here in XTJ , we have certified CNC machining facilities. Through CNC machining, we are able to offer rapid prototyping as well as low production volume of different parts. Additionally, XTJ offers custom CNC machining parts services according to your needs.

Aside from that, XTJ provides CNC machining parts services for different industries such as medical, oil and gas, aerospace, automotive, industrial, and more.

CNC Machining Parts Process Expert in China

Materials Used for CNC Machining Parts

XTJ carefully sourced high-quality materials for CNC machining parts to meet precise and demanding applications. XTJ uses different metals including:

- Aluminum

- Brass

- Copper

- Bronze

- Steel alloy

- Stainless steel

- Steel mild low carbon, and more

XTJ CNC Machining Parts Processes

XTJ has full capabilities of providing different CNC machining parts processing such as the following:

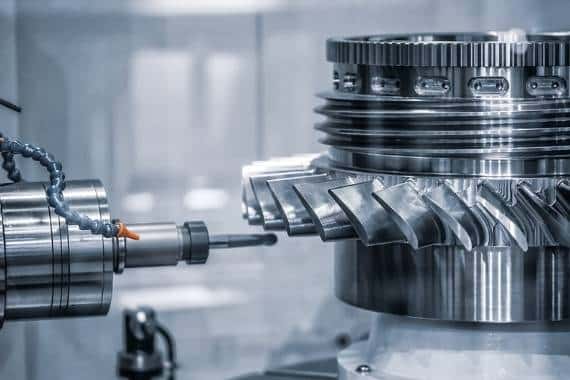

- CNC Milling. XTJ uses CNC milling for faster end-use parts production and custom prototypes. We are equipped with 3-axis and 5-axis milling processes for producing different parts. CNC milling is mostly used for jigs and fixtures, functional prototypes, and low volume production of components.

- CNC Turning. XTJ is an expert in CNC turning for manufacturing custom prototypes and parts. We use CNC turning for producing different parts with cylindrical, slots, radial holes, grooves, and flat features.

- EDM or Wire EDM. XTJ is offering EDM services for pressure die-casting and injection molding. XTJ EDM services can provide tight tolerances and superior surface finish to the machined parts.

XTJ CNC Machining for Complex Parts

CNC machined parts are varying in terms of complexity. Some parts require a simple design to complex curved geometries.

Here in XTJ, we are fully equipped with different types of CNC machines suitable for producing complex parts.

We have a complete set of CNC lathes. It is a 5-axis machining center or 3-axis CNC milling machine that is used for producing CNC parts with complex shapes.

Therefore, we assure that all CNC machined parts have accurate dimensions and tight tolerances.

Advantages of XTJ CNC Machining Parts

CNC machining offers lots of advantages for different component production. It is ideal for both rapid prototyping and volume production.

Here are some lists of CNC machining parts advantages:

- Easily customized

- Superior surface finish

- Suitable for different materials

- Suitable for producing complex parts

- Low tooling and preparation cost

- Fast turnaround

- Repeatable, precise, and accurate

- Versatility

Surface Treatments Used for CNC Machining Parts

Bead Blasting

Bead blasting surface treatment removes any imperfection or surface deposits on the CNC machined part. Thus, creating a smooth and uniform finish. It uses a sphere-shaped bead to provide a consistent matt finish. A dull finish or satin-like finish can be achieved using a finer bead.

Uniform satin or matte finish

Low cost

Anodized Finish II (Clear or Colored)

The anodized surface treatment uses a wear-resistant coating on the CNC machined parts. Thus, making the machined part resistant to corrosion. Usually, anodized parts come in different colors. It typically has a thin and transparent layer.

Aesthetically-pleasing

Excellent dimensional control

Suitable for small parts and internal cavities

Anodized Finish III (Hardcoat)

This surface treatment is only available for titanium and aluminum CNC machined parts. It provides more protection than an anodized II finish. It can also be dyed with different colors while providing maximum corrosion and wear resistance.

Powder Coating

This surface treatment allows an additional thin layer of protective polymer on the machined part surface. It is suitable for most metal materials. Advantages of powder coating include:

Wear resistance, corrosion resistance, and strong

Higher impact resistance

Available in multiple colors

As Machined Finish

This surface finish allows surface roughness to the machined parts. The surface roughness can be determined using the Ra value. The typical surface roughness of the machined part is Ra 3.2µm.

Advantages of as-machined finish:

Provides maximum tight dimensional tolerances

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.