Humans have been making tools, structures, artwork, and other products from metals for thousands of years. Ancient gold jewelry and coins and antique iron cookware are a few well-known examples.

Today, however, we’re surrounded by more metal products than ever before. Metal fabrication is an essential part of manufacturing for both consumer goods and industrial parts and equipment. But what exactly does this term mean?

Metal fabrication is the creation of parts, products, or structures from raw metals. This means using one or more metal fabrication processes to shape, bend, cut, or assemble metal stock into a finished or semi-finished product.

The Types of Metal Fabrication Processes

Every day, copper, aluminum, iron, titanium, stainless steel, nickel, gold, silver, and a wide range of other metals and alloys are fabricated into new metal parts. But the manufacturing process applied to one metal might only work well for some metals. And even for the same metal, using a different processing technique can produce different results.

For example, die casting is only used for metals with relatively low melting points, like aluminum. But we can also expect the microstructure and properties formed by die casting aluminum to differ from extruded or 3D-printed aluminum.

Each metal fabrication process has its own strengths and limitations, which we don’t have room to explain in this article. Instead, the following lists give a brief insight into the wide range of options available to fabrication shops and other metal part producers.

1) Forming and shaping processes

Sheet metal bending

Forming and shaping processes include a variety of fabrication methods used to turn raw metal stock into a different shape without adding or removing any significant amounts of material. Generally, the raw metal stock is either melted and cast inside a mold, or heated until it becomes malleable and then reshaped into a new part.

Here are a few common forming and shaping processes:

Casting, including die casting, sand casting, investment casting, etc.

Forging

Rolling

Extruding

Bending (shown above)

Additive manufacturing, also known as 3D printing

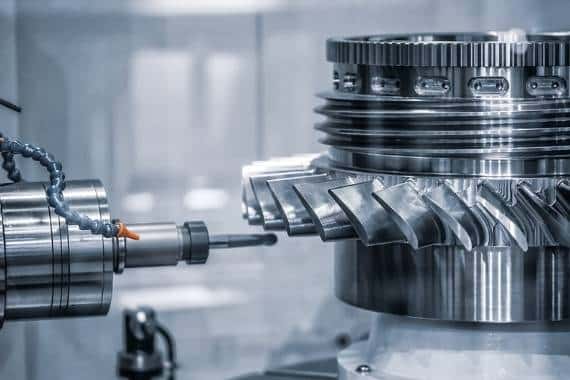

2) Cutting and machining processes

Milling cutter with metal splinters

Cutting and machining are subtractive manufacturing methods because they selectively remove material from a basic component to form new parts. Traditionally, this was limited to using drills, mills, lathes, saws, and shears to apply precision features to parts, but new cutting and machining processes are being used alongside traditional methods to increase productivity.

Some popular cutting and machining processes include:

CNC milling (shown above)

CNC turning

Drilling

Sawing

Shearing

Laser cutting

Plasma cutting

Waterjet cutting

Electrical discharge machining (EDM), including wire EDM

3) Welding and joining processes

GMAW/MIG welding

Whenever two or more components need to be assembled together, welding and joining methods are required. Here are some well-known welding and joining processes:

Gas metal arc welding (GMAW), also known as MIG welding

Gas tungsten arc welding (GTAW), also known as TIG welding

Shielded metal arc welding (SMAW), also known as stick welding

Laser beam welding (LBW)

Brazing and soldering

Riveting and fasteners

Threaded connections and other locking connections

The Value of Metal Fabrication to Modern Manufacturing

Metal utensils

When you pause to think about how many products are made from metals, you realize how essential metal fabrication is to modern manufacturing.

Utensils and cookware, furniture, consumer electronics, structural supports, architectural features, automotive parts, aerospace assemblies, pipelines, cranes, and much more rely on metal fabrication. The parts used in the majority of these applications will rely on multiple fabrication methods to create the finished product.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.