How to Plunge Cut with a Fixed Base Router Step by Step?

If you work in a professional woodworking shop, you already know the importance of a fixed base router! Yes, it does all the work of cutting without taking the help of any other equipment. But do you know you can also plunge cut with this one?

Yes, you can! And how to plunge cut with a fixed base router if you do not have a plunge router? We will tell you every detail, from the router bits to use, to cleaning afterwards. Here is the method of cutting the perfect plunge cut without having a plunge router.

How to plunge cut with a fixed base router?

Step by Step Fixed Base Router Plunge Cut

Go through this step-by-step method of making a plunge cut with the help of a fixed base router. Basically there is no need to invest in any other equipment anymore.

Step 1: Get the Jig

First of all, you have to get a jig so that it is easy for you to keep the router base added to the bit cuts. If you do not use it, the router base will start moving when you are working. And eventually, it will get out of control, also keeping the raw materials besides! So, the first job is to get the jig set up for your safety.

Step 2: Examine the Base

Go through the jig and check the three particles. A 1/4 –inch plywood is used for the base here. There is a cut down in the middle too. This is for the approval of a straight bit. And then you will see a set of two fences. They will be set beside one another. These fences are 2’ x 4’ and are set in one straight line on top of the router base. Here, the cutting range will be marked with the top blocks.

Step 3: Set it up

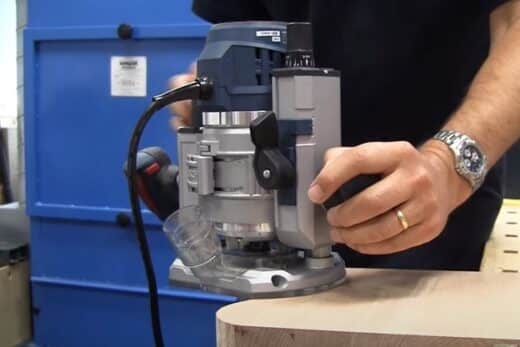

The setting of the bit should be set for an immense cut of ¼ inches. Make sure to set it properly. Once you are done, you have to get your hands on the router and position it at an angle. Go through the router base’s one side. Hold it against the jig’s base. Make sure your hand is firm enough to hold it strongly. Slowly, you have to get your hand on the bit and take it low.

Take it into the slow inside in your jig. After a while, you will see that the router is leveled on the base of your jig. When you switch on the router, make sure you are noticing the sound of your motor. It is an easy way to tell if the router is cutting the wood properly and safely or not.

Step 4: Start Working

It’s time for you to start the router. Hold it and flit it both backward and forward. You have to stop at the boundaries at the front and back. Yes, the routing direction might confuse you. But you don’t have to worry about it. Indeed, keep in mind that in order to keep the router aligned you need the fences in place.

Some shallow passes might be required depending on how extreme you want to cut. While operating the router, make sure that you are going for the speed that you can handle. In brief, make sure you have control over the speed of your router. Also, nourishing the router bit into the material firmly is necessary.

Step 5: Stop and Clean

After you are done, make sure you do not let the router get out of your hands. By all means you have to firmly hold the handle of your router till the motor of the router stops moving or working. If you think that there are any issues or you have to fix the router down, make sure that the motor of the router stops first and then you go for it.

While operating, do not try to get into its work, it might result in an accident. Your safety is paramount in this process. After the work is done, you have to switch off the router. But don’t forget to clean it. There will surely be particles that will stick into the router. You don’t want the router having any issue with starting the next time you use it, right! So, go through the parts of your router and clean them carefully.

FAQs on Cutting Plunge with Fixed Base Router

Is a plunge router different from a fixed base router?

Yes, there are differences between plunge routers and fixed base. The bit of the fixed base one, as the name says is designed to be set in a fixed position. And you can lower the bit of a plunge router and keep the base plate flat on the stock. However, both the plunge router and the fixed base router have adjustable depths for cutting and you can select them according to your preference.

What does a fixed-base trim router do?

As the base of the fixed base router stays in the same position, you will get a good grade of precision while working. Along with this, they have the cutting depth preset. So, you won’t be dealing with any human error with this one. A fixed base router is loved for joinery projects because they are great for working from the sides or edging!

Can I use a plunge router for edges?

Both the plunge routers and the fixed base router are amazing for working with the sides or the edges, especially for decorative cuts. At times, you need to work on the inner part of a surface.

In the case of the keyhole slots or mortises, this happens often. And this is where the plunge router comes in. The best part is you can get routers that are available for switching between plunge bases and fixed bases. These are great for both jobs!

How to plunge cut with a fixed base router

Now you already know how to deal with a fixed base router and make plunge cuts with this one. The steps are easy and all you need is to pay attention!

Try not to forget that you must always wear the necessary protective gear for woodworking or metalworking before you start the work process. And trust us, above all the method isn’t going to disappoint you.

Comments on this guide to how to plunge cut with a fixed base router? article are welcome. We welcome your advice on this cutting process explanation.

- Do you have a different take on this subject?

This is one of our most popular help guides on e-architect so we are happy to get advice on how to improve it!

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of 303 steel,304 steel from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.