During the initial stages of product development, a critical decision revolves around selecting the suitable manufacturing technology. This frequently involves a side-by-side assessment of additive and subtractive manufacturing. In this article, we’ll outline these two manufacturing methods, identify which processes fall into which category, and explain how you can get the best of both worlds by combining the two.

Additive vs subtractive

Additive Manufacturing is the process by which an object is created by adding material. Layers are built on top of one another and are bonded together, resulting in the creation of a 3D form. You could think of additive manufacturing as the same concept as bricks being laid to produce a wall.

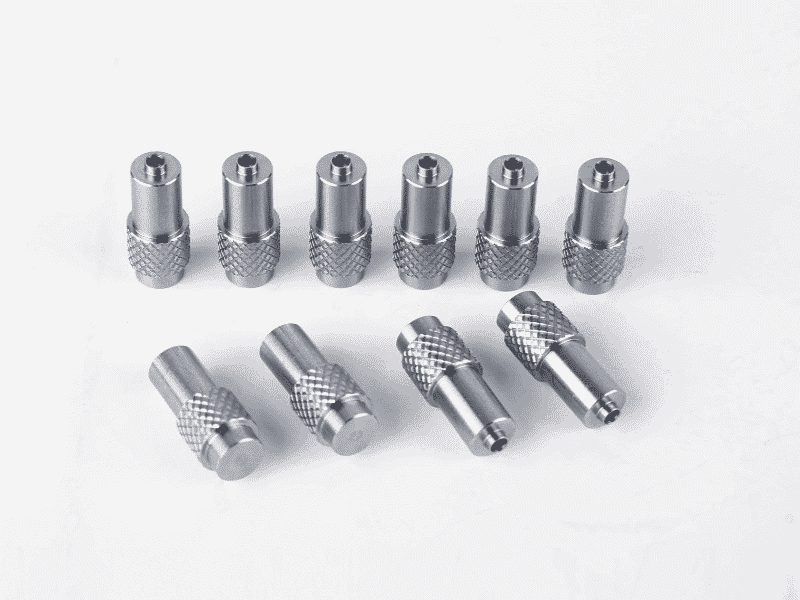

Subtractive Manufacturing is however the opposite, material is subtracted, or removed in order to produce a 3D object. It is revealed underneath a block of material through cutting, drilling, and filing — in the same way a sculptor would create their masterpiece. To see a video example of this, click here.

additive and subtractive manufacturing processes

3D printing is probably the most widely recognised example of additive manufacturing, so much so that the terms are used interchangeably. The term describes a process where a device uses a digital model as a reference to lay down material (metal or plastic) layer by layer to produce an object. 3D printing is an umbrella term that describes a range of processes, including:

SLA or Stereolithography

SLS or Selective Laser Sintering

DMLS or Direct Metal Laser Sintering

MJP or Multi-Jet Printing

MJF or Multi-Jet Fusion

FDM or Fused Deposition Modelling

Examples of Subtractive Manufacturing Methods:

CNC milling/turning

EDM or electrical discharge machining

Laser Cutting

Waterjet Cutting

Table of Contents

What is CNC Milling and What is it Used for?

If you are interested in learning more about any of the above processes, you can find more information here. Or, if you have any questions or you would like to speak with us in more detail,

Which manufacturing method is best for your project?

Despite being categorised differently, additive and subtractive manufacturing methods aren’t mutually exclusive and are best utilised alongside each other. This way, you can get the best of both worlds. When answering this question, you should consider:

What are the characteristics of my product?

How big is it? Is it complicated or simpler in design? If it’s small, then generally speaking, additive is the way to go. This process lends itself very well to producing smaller items with intricate details. Whereas, subtractive processes are better suited to larger, less complex designs without features such as enclosed cavities, which aren’t possible to achieve with subtractive methods.

What is my object going to be used for?

Does your part play a weight-bearing role? Does it need to be strong? In this case, subtractive methods are generally better because the item is one form that has been carved out of a solid block. Therefore, it doesn’t have weak points where different sections were once bound together, as products of 3D printing will. Additionally, the materials that subtractive methods can manufacture are generally harder and stronger, as these materials aren’t subject to melting points as 3D printing material is.

How far along am I in the design process?

Often the chosen manufacturing process depends on how far into the development process the part is. Additive manufacturing works very well for the early stages of development, as 3D printing offers low-volume manufacturing with a high degree of design freedom. And, generally, objects can be produced faster and more economically at this stage with additive rather than with subtractive methods. However, as the design process goes on, the customer may require larger batches. This is where subtractive manufacturing comes into play, as more are ordered, the more economical the production becomes. In addition to this, subtractive manufacturing offers a much wider range of finishing options for parts, so it may be the best method to produce a final version of your design.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.