It is complicated to create inner and outer profiles on traditional milling machines because the spindle must be constantly repositioned in order to reach the different areas of the workpiece. Although this process can be time-consuming and lead to inaccuracies, broaching and slotting are two of the more common methods. We will cover throughout this article the ins and outs of slot milling and the tools used for these operations.

Table of Contents

Introduction to Slot Milling and Slot Cutters

Slot milling is a type of milling operation in which a rotating cutting tool is used to remove material from a workpiece by moving it in and out of a slot. This type of milling is typically used to create keyways, slots, or pockets.

Compared to other milling operations, slot milling is typically used to cut deeper slots or pockets than what can be achieved with end milling for example. Additionally, it often produces a cleaner and an excellent surface finish.

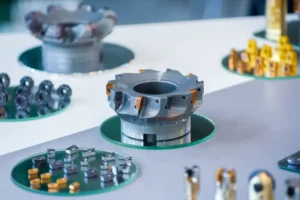

Slot milling cutters are extremely versatile tools that have multiple teeth mounted in a circular pattern on a spindle. They are used to machine solid-jaw mandrels, guide bars, and flat parts from metal stock.

The different types of Slot Milling Cutters

Slot milling cutters are cutting tools used to machine slots (grooves) in a workpiece. There are different types of slot milling cutters, selected depending on the shape, size, and width of the slots they are able to produce. Both a face milling cutter and end mills are capable to handle the job. However, each has its advantages and downsides.

Face Milling Cutter

The face milling cutter is usually more accurate because it uses a fixed cutting edge that is always on the same horizontal plane of motion as the workpiece. However, one of its most prominent advantages is that it has adjustable widths and depths which allows for machining a broader range of products.

On the other hand, it is quite limiting and can only be used for linear grooving. In addition, Face mills are not well suited for finishing operations as they can chatter and vibrate, causing poor surface finish and reduced accuracy

End Mills

The end mill can be set at any angle to the workpiece. It is a more versatile tool that allows for additional operations such as semi-finishing. End mills are especially useful for machining shallow and closed slots.

The main disadvantage of using an end mill for slot milling is that it can leave a rough finish on the material. Additionally, end mills are not well-suited for cutting very hard materials or materials with high tensile strength.

A Slot Cutter’s Main Components

A slot cutter is a powerful tool that can be used to cut slots in a variety of materials. There are several different types of slot cutter machines, each with its own unique set of features and benefits. Let’s take a look at the main components of a slot cutter machine.

- Table: The table is where you will place your workpiece. It is also where the blade will be mounted.

- Base: The base of the machine is where all of the other components are mounted. It also contains the coin tray and the bill acceptor.

- Guide: The guide is used to keep the milling cutter in place and ensure that it cuts the slots in the correct location.

- Cross-slide: The cross-slide is the horizontal platform that the workpiece is mounted on.

- Ram: The ram is the vertical platform that the tool is mounted on.

- Handwheel: The handwheel is used to move the tool up and down.

Applications of Slot Milling

The slotting machine can be used to perform a wide array of operations, of which we can find:

- Machining special and intricately shaped parts with both inner and outer profiles. It is designed to cope with long-running and especially heavy machining processes. This is achieved by the use of robust construction, which is also ideal for machining metal plates.

- While slotting is an effective method of removing metal, it can also be used to remove wood or other materials. This type of machine is useful for creating intricate parts and shapes from various materials.

- Shaping surfaces with different shapes (concave, convex, circular, semi-circular…etc.). It may also be used for CNC milled parts.

- Machining vertical surfaces.

- Machining sloped or inclined surfaces.

Tips for machining complex parts with a slot cutting tool

Slot cutters are one of the most versatile tools in a machinist’s toolbox. They can be used to create a wide variety of shapes and sizes, and they’re perfect for machining complex parts. Here are some tips to help you get the most out of your slot milling cutter.

Use a slot milling cutter with a smaller diameter.

The blades in a slot milling cutter can come in all shapes and sizes, including circular and straight. However, most of the time, you’ll want to use a smaller size so that you have less material to cut at one time. To achieve this effect, make sure you’re using a cutting tool that has a smaller diameter.

Match the blade size to the material.

Not all materials are the same. Make sure you match the blade size to the material that you are machining so that you have the proper clearance.

Use a slot cutter in combination with other tooling.

One of the best ways to increase productivity with a slot milling cutter is to use it with other types of machining tools.

Use a large cutting depth.

Slotting cutters can take a wide range of cutting depths depending on the type of tool and the material. Most of the time, you’ll want to use a large cutting depth for faster production and more frequent tool changes.

Slotting can be executed in a machining center. If you’re looking for high-quality surface finishing, look no further than Xin Tian Jian. We provide top-notch surface finishing services for all components regardless of their machining method. A few of our skilled professionals only handle finishing assignments, so the quality of work we do on your products is second to none. If you desire a flawless finish for your prototypes and other manufactured components get in touch with our customer service team for a quick and accurate quotation.