Are you interested in learning about CNC machine parts? Do you want to enhance your knowledge and utilize these parts effectively? In this comprehensive guide, we will dive deep into the world of CNC machine parts, providing you with everything you need to know. Whether you are a beginner or an experienced professional, this article aims to address all your questions and concerns regarding CNC machine parts.

The Purpose of the Article

The purpose of this article is to educate and familiarize readers with CNC machine parts. By the end of this guide, you will have a clear understanding of the various components that make up these machines and their functions. Whether you are a technician, operator, or someone who simply wants to gain knowledge, this comprehensive guide will serve as a valuable resource.

Overview of CNC Machine Parts

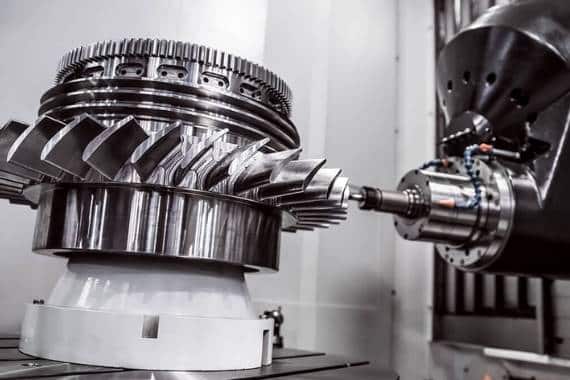

CNC stands for Computer Numerical Control, and CNC machine parts play a crucial role in the efficient functioning of these machines. These parts contribute to their accuracy, speed, and precision in manufacturing processes. Therefore, understanding the composition and functionality of CNC machine parts is essential for optimizing their usage.

1. Motors: The motors in CNC machines are responsible for controlling the movement of the machine’s axes. They ensure precise and accurate positioning of the workpiece for various machining processes. Step motors and servo motors are commonly used in CNC machines.

2. Stepper Motors: Stepper motors provide precise step-by-step motion control to the CNC machine. These motors are essential for achieving accurate positioning of the tool or workpiece during machining operations.

3. Servo Motors: Servo motors offer continuous motion control to the CNC machine. They are known for their high torque, high speed, and excellent positioning capabilities. These motors provide improved accuracy and responsiveness in CNC machining.

4. Spindle: The spindle is a crucial component of a CNC machine that holds the cutting tool. It rotates and provides power to the tool, enabling effective cutting, drilling, or milling operations. The selection of the spindle depends on factors such as horsepower, speed range, and tooling compatibility.

5. Control Panel: The control panel consists of various buttons, switches, and a display unit that allows operators to program and monitor the CNC machine’s operations. It provides an interface for entering commands, modifying settings, and troubleshooting issues.

6. Tool Changer: CNC machines often feature automatic tool changers, which allow for on-the-fly tool swapping. These tool changers enhance efficiency by eliminating manual tool changes and reducing downtime during machining operations.

7. Worktable: The worktable serves as the platform where the workpiece is placed and secured during machining processes. It can be fixed or adjustable based on the specific requirements of the CNC machine and the desired machining operations.

8. Coolant System: CNC machines employ coolant systems to dissipate heat generated during machining operations. These systems help maintain tool temperature, improve tool life, and ensure the quality of the finished products.

9. Control Software: The control software acts as the brain of the CNC machine. It converts the programmed instructions into commands that the machine understands. The software enables precise control over the machine’s movements, tooling operations, and various machining parameters.

10. Cutting Tools: Cutting tools, such as drills, end mills, and reamers, are essential CNC machine parts used for shaping and finishing operations. These tools undergo wear and tear during machining, requiring regular inspection and replacement to maintain optimal cutting performance.

Expertise in Door Hardware Fields

As a leading expert in the field of door hardware, I have extensive knowledge and experience in utilizing CNC machine parts for manufacturing high-quality door components. By leveraging the precision and efficiency of these parts, I have successfully contributed to the innovation and advancement of door hardware technologies.

Throughout my years of experience in the industry, I have witnessed firsthand the vital role CNC machine parts play in achieving superior quality and precision in door hardware production. By understanding the intricacies of these parts, manufacturers can optimize their machining processes and deliver exceptional products to customers.

In conclusion, CNC machine parts are essential for the efficient and accurate functioning of CNC machines. By familiarizing yourself with these parts, you will be able to enhance your understanding and utilization of CNC machines. Whether you’re a technician, operator, or simply someone interested in this field, this comprehensive guide has covered all the necessary information to empower you in the world of CNC machine parts.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Auto Parts from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.