In order to maintain the country’s security, the military must have access to the best quality components for their aircraft, ships, and weapons. That’s why many businesses that work with the military choose to use CNC machining. This type of manufacturing process uses computer numerical control to create high-precision parts and products. When it comes to the military, CNC machining is a vital tool.

The Importance of Quality Military Components

The military and defense industry covers a wide range of products, services, and technologies. from small arms and ammunition to aircraft, missiles, and spacecraft. The industry also includes companies that produce military vehicles, electronic systems and equipment, and other defense-related products. Military and defense product companies serve many functions within their respective industries, from research and development to manufacturing and even design.

The importance of accuracy and precision in the military components manufacturing process cannot be overstated. The slightest error in the manufacturing process can result in a component that does not meet the required specifications, which can ultimately lead to a failure in the field. In some cases, such failures can even result in loss of life. That is why it is so important for manufacturers of military components to adhere to the highest standards of accuracy and precision in their manufacturing processes.

CNC Machining For the Military & Defense Industry

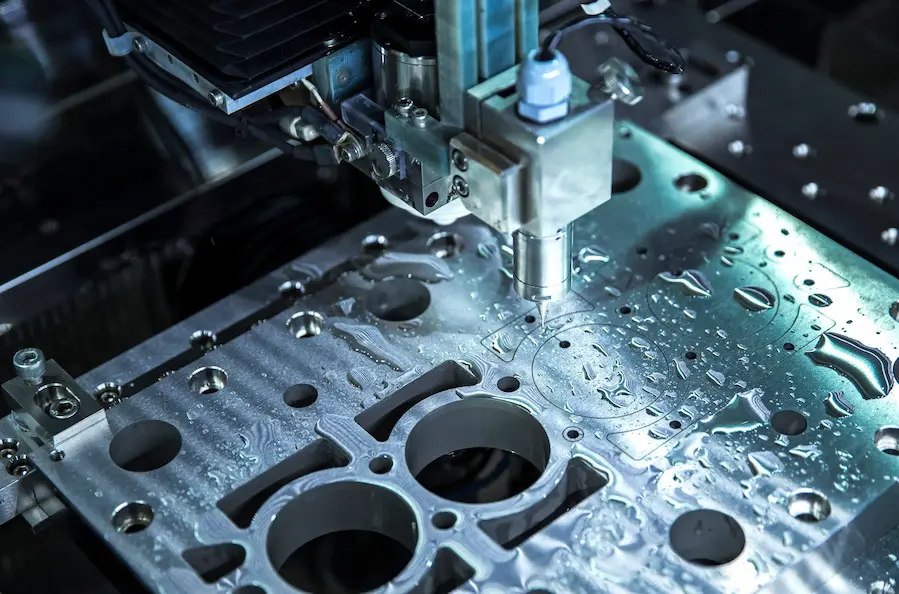

CNC parts have a wide range of applications in the military and defense industries. From small, intricate parts used in electronics and weaponry to large structural components used in aircraft and vehicles, CNC machining can produce parts with tight tolerances and complex geometries that meet the demanding requirements of these industries.

CNC machining can help military and defense contractors reduce lead times and costs by helping them build faster and better. This technology is ideal for creating prototypes and low-volume production runs. It also allows companies to produce parts that would not be feasible to manufacture through traditional manufacturing methods.

When the demands of the military and defense industries are coupled with ever-increasing cost pressures, CNC machining is often the most efficient way to meet those needs. Xin Tian Jian Machining is a CNC machining service provider with military-level precision. We offer high-quality military components, such as pistols, rifles and machine guns, precision parts, and firearm accessories.

5-Axis CNC Machining is a Great Option For a High Precision and Accuracy in Military Parts

The military manufacturing industry uses a variety of CNC processes and machines to produce parts and components for a wide range of applications. These include lathes, mills, routers, and grinders. Each type of machine has its own strengths and weaknesses, and the best choice for a particular application depends on the specific requirements of the project.

5-Axis CNC Machining is used extensively in the production of military parts. The ability to machine complex shapes and contours in a single setup reduces production time and costs. In addition, the precision and repeatability of 5-Axis CNC Machining make it ideal for producing critical components such as missile guidance systems and aircraft engine parts.

It is also used to produce components that require the creation of complex curves, shapes, and other structures. For instance, the development of aircraft engine fuel injectors and transmission gears relies heavily on 5-Axis CNC Machining. The 5-Axis CNC Machine is the most popular machine in this category.

The Future of CNC Machining for the Military

The military machinery industry is forecast to grow significantly in the next decade. This growth will be driven by the increasing demand for military equipment and machinery, as well as the need for more sophisticated and technologically advanced products.

CNC machining will play a vital role in this industry, providing the necessary precision and accuracy for the production of these products. In addition, CNC machining will also allow for the mass production of these products, which will be essential in meeting the demands of the military.

Our Military-grade CNC Machining Services

At Xin Tian Jian, we have a wide range of machines and capabilities that allow us to produce parts that meet the most stringent specifications. We also work with a team of experienced engineers and highly-skilled technicians who are familiar with the unique requirements of the military and aerospace industries. This allows us to meet the demands of your production line by providing parts with all of the necessary dimensions and tolerances, as well as machining parts that are impossible to cut using conventional equipment.

High-quality military components for defense

Our CNC machines are capable of producing high-quality components with tight tolerances, ensuring that your finished products meet the highest standards.

Quick turnaround times

We are able to provide quick turnaround times, which translates into being more cost-effective for our customers.

A complete range of CNC machining services

We offer an expanded range of CNC machining services for our customers, allowing us to be more competitive and profitable. Whether it’s milling, drilling, polishing, or grinding, our experienced workforce can handle any job. With our CNC machine tools and highly-skilled staff, we strive to provide top-notch service that you can trust.

Contact Us to Discuss Your Component Requirements Today

If you’re looking for a company that specializes in CNC machining for military and defense applications, look no further than XTJ Machining. We have the experience and expertise to provide you with the highest quality parts and components, backed by our commitment to customer satisfaction. Contact us today to discuss your project and learn more about what we can do for you.