A surface finish symbol is a mark found on pieces that have been machined by either turning, grinding, or boring. Surface finish symbols are not the same across all industries. For example, while metric and U. S. measurements may use different processes, they both generally indicate if an edge has been chamfered on one side or another by using the same marks, just different meanings assigned to them.

The purpose of a surface finishing symbol is to visually designate the results of a machining process. The main purpose is to help find and identify pieces that have been machined by specific processes without having to conduct research on individual machines. This can save a great deal of time and effort for both customers and suppliers.

There are a few different symbols used to signify surface finish on parts, and each surface finishing symbol can have different meanings. The main differences between surface finish symbols are based on what type of process was used to machine the piece, whether or not the part is flat, and how the corner has been chamfered. We will discuss this in detail in this article.

Table of Contents

Definition of Surface Finish

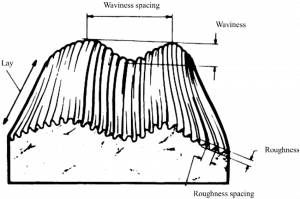

A surface finish is the appearance of a surface. In industrial design and engineering, it is the result of a process that alters the surface topography of an object. A good surface finish is important for the appearance and function of an object. There are many factors that affect the surface finish, including the type of material, the method of finishing, and the environment. The texture of a surface can be characterized by its lay, surface roughness, and waviness.

Lay

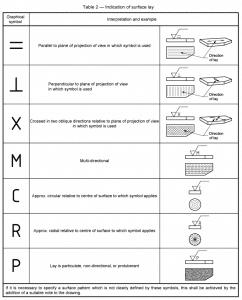

The lay of a surface is the direction of the predominant fibers in the surface. It is important to note that the direction of fibers in a surface is not necessarily constant over time. This is due to erosion by chemicals or mechanical stress. The lay of a surface can also be affected by variations in the pH of an environment and temperature.

Surface Roughness

The roughness of a surface is a measure of the size and distribution of bumps and indentations on the surface. The largest and most noticeable bumps and indentations are called macro-texture. The smaller bumps and indentations are called micro-texture.

Waviness

The surface is smooth if the waves are small and evenly spaced. A rough surface has large waves or no waves at all.

One of the most important factors is the roughness of the surface. It is a measure of the smoothness of the surface and is usually quantified by the roughness average (Ra) or the peak-to-valley height (PV). Roughness measures the non-planar, or wavy nature of a surface. Peak-to-valley height measures the curvature of a surface and is determined by the effect of rounding on flat surfaces.

RA: Average Roughness

Surface finish units are a way to measure the roughness of a surface. The most commonly used surface finish unit is Ra, which measures the roughness of the surface by dividing the average roughness (Ra) by the profile height. Ra is defined as the average of the absolute value of all points in a surface profile that are less than mm from a reference point on the reference surface.

The average roughness of a surface finish is determined by the peaks and valleys in the surface. The rougher the surface, the higher the average roughness. This can be important to consider when choosing a surface finish for a particular application, as a rougher surface may not be as smooth as desired. The common surface finish unit Ra is defined by the following equation:

Ra = ( ρ average ) / h profile ( Ra = average roughness of a surface )

PV: Peak to Valley Height

The peak to valley height of a PV surface finish is an important factor in determining the quality of the surface. In general, the higher the peak to valley height, the better the surface finish.

However, if the peak to valley height is too high, which causes secondary particle growth, the surface may become too rough, but may also be more prone to defects. Therefore, choosing the proper peak to valley height for a PV surface finish is important for good quality.

To determine the peak to valley height of a PV surface finish, it is necessary to calculate the average angle between the potential height and the perpendicular line from the front face to the free surface. Then the ratio of this angle to the width of the PV surface finish can be used to calculate the peak to valley height.

Surface Finish Symbols and Their Meaning

A surface finishing symbol is used to indicate the quality of a surface. It can be used to describe the appearance of a surface, or the feel of a surface.

Different parts of the world have different surface finish symbols and standards. The ANSI standard is commonly used in the United States, while the ISO standard is more popular elsewhere in the world.

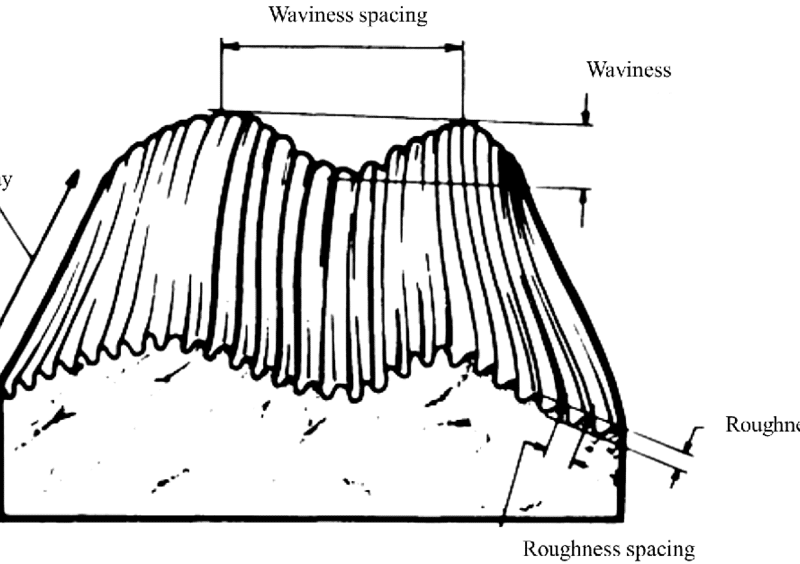

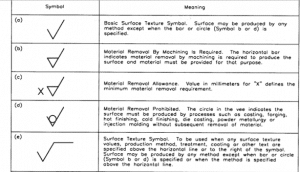

Different surface finishes can use different callouts and symbols, so we’ll take a look at some:

ISO Surface Finish Symbols

The ISO surface finish symbols provide a standard way of representing the surface finish of a manufactured component. Each surface finishing symbol is used to communicate the surface finish to other engineers and manufacturers, and can be used to compare the surface finish of different components. There are a variety of different symbols, each representing a different surface finish.

ANSI Surface Finish Symbols

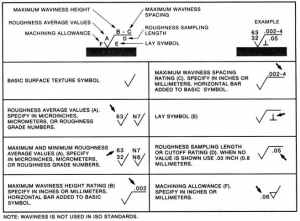

The American National Standards Institute (ANSI) has a set of surface finish symbols that are used to indicate the quality of a surface. These symbols are used to help manufacturers and buyers communicate about the surface quality of a product.

The symbols define the situation of the creases made by the edged tool during machining to the surface captured in the diagram in which the symbol is written. The arrow represents the direction of the movement. The symbol of a circle is the point of application of the initial load on the surface (an edge tool, for example).