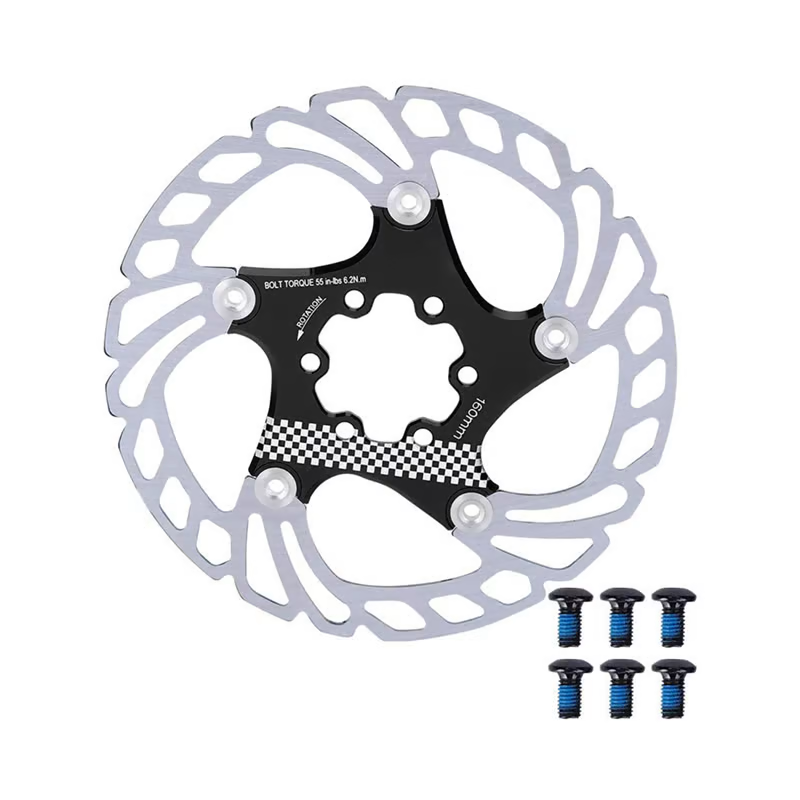

Aluminum Alloy Mountain Bike Brake Rotor

Specification:

Condition: 100% brand new

Item type: Bike Floating Disc

Material: Aluminum alloy inner frame + stainless steel outer frame

Optional Color: black + silver, red + silver

Size: Approx. 203mm/8in

Hole distance: the center distance to the hole is 44mm/1.7in

Weight: Approx. 230g

Process: CNC engraving and milling, anodizing, stamping forming

The floating disc appears to solve the problem that after the continuous friction temperature rise of the integrated disc, the temperature at the center of the disc is different from that at the edge green position due to thermal expansion and contraction, resulting in internal tension.

Generally speaking, there are two kinds of materials inside and outside the floating disc, which are connected by rivets. This connection is not rigid. The thermal attenuation is related to the high temperature resistance of the material, and the floating disc will not reduce the thermal attenuation. However, if the disc material and design are optimized and the heat dissipation capacity is strengthened, the anti attenuation ability will be improved.

Process: Aluminum Die casting, Zinc Alloy die casting,CNC machining,Surface Treatment

Production Equipment: Cold chamber die casting machine:280T/360T/400T/500T/800T/1250T.

CNC Centers.

CNC Lathes.

Inspection Equipment: CMM,X-RAY

Material: Aluminum Alloy: Aluminum AL7075-T6, A319, A356, A360, A369, A380, A383, A384, A413, A535, 44300, 44300, 46000, AlSi9CU3, ADC12, ZL102, ZL104, ZL108, YL112

Zinc Alloy: Zamak 2,3,5,7 ect.

Surface: Trimming, Deburring,Polishing, Sand blasting,Vibration, Powder coating, Anodizing, Chrome

Software Assistance : Pro-e/Solid work/UG/Auto CAD

Bike Brake Rotor, 203mm Aluminum Alloy Mountain Bike Type Floating Brake Disc Bicycle Brake Rotor with Bolts Cycling Accessory Fit for Road Bike Mountain Bike

The reinforcement of aluminum alloy bracket completely solves the problems of rivet rubbing clamp and strength.

Two kinds of materials inside and outside the floating disc are connected by rivets. This connection is not rigid and has a certain amount of free, which reduces the heat transfer.

Stainless steel floating button design, so that the outer dish is not directly locked with the hub, leaving expansion space.

CNC precision manufacturing, high hardness.2 different colors for you to choose, meet your different needs.

Advantage

Competitive factory price and superior quality

Professional and experienced technology team

Focus in high precision CNC machining

Consistently meet the tight tolerances required

Low MOQ and free sample

Short lead time (20 working days)

ISO9001:2008 certification and materials accord with Rohs standard

Excellent after sale service and good warranty

Our service:

Electronic and communication, Aerospace, Optical instrument, Medical and pharmaceutical,

Oil, gas and petroleum, Railway, electric tool, car, robot, hydraulic equipment

Equipments:

CNC Machining Center, CNC Lathes, CNC Milling Machines, wire cutting, laser cutting

Stamping machines , Assembly lines, Whole set of measurement tools

Precision Processing:

CNC machining, CNC milling and turning, laser cutting, drilling, grinding, bending, stamping, welding and so on

Drawing format

JPEG,PDF,DWG,DXF,IGS,STEP.CAD or according to your sample

Material

Stainless Steel, Brass, Aluminum, Steel, Carbon Steel, Titanium , plastic. Or other Exotic Alloys

Surface Finish

Anodize; Blacken, polishing, plating, sand blasting

Tolerance

+/- 0.002 –0.20 mm / can also be customized.

Inspection

100% inspection before shipping

Payment Terms

30%T/T in advance, the balance before delivery; Paypal is acceptable

Quotations:

Drawings (CAD, STP, PDF formats) or Sample

Quantities; Materials; tolerance; surface treatment or other special requirements

Our engineer can offer technique supports to design or modify drawings according to requirements from customers

Lead Time:

Sample Lead Time: 3~7 days

Production Lead Time: 10~30 days based on different products

Shipment time: 7 days with DHL/FEDEX/UPS; 20 days with fast Ocean shipment; 30~45 days with Normal Ocean Shipment

Quality Guarantee:

We have IQC inspect all raw materials at incoming department

IPQC inspect and measure the machining parts during mass production

OQC inspect and measure the finished products according to Drawings and SIP documents with MIL-STD-105E

We guarantee all products/parts comply with drawing and other quality criteria requirements on the contract and approval documents, will rework all defect products or refund to customers if receive

non-good products.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.