injection molding can also be used to make flexible moldings: parts that are soft, pliable, shock-absorbing, ductile, or elastic. Products like hand grips, gaskets, protective smartphone covers, and certain medical implants all require a rubber-like material in order to perform their function, and injection molding offers two standout material options for making such products.

The first of these materials is liquid silicone rubber (LSR), a thermoset that requires its own special variant of the injection molding process. The other is a group of thermoplastics known as thermoplastic elastomers (TPEs), which can be processed like common rigid thermoplastics but which offer rubber-like properties.

This article examines the XTJ vs TPE injection molding discussion, comparing material properties, advantages and disadvantages, and suitable applications.

Table of Contents

What is liquid silicone rubber?

Liquid silicone rubber is a high-purity form of cured silicone. It is a chemically inert thermoset with material characteristics such as biocompatibility, chemical resistance, water resistance, excellent compression set, flame retardancy, and heat resistance up to 250 °C.

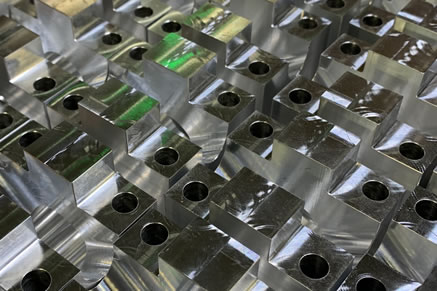

Injection molding XTJ requires a special process generally known as liquid silicone rubber molding. Unlike a standard injection molding machine, the equipment comprises a metered pumping device for dispensing the two liquid materials (catalyst and base forming silicone) and a mixer for combining the materials before they enter the mold. The mold cavity is heated, allowing vulcanization of the silicone to take place within the cavity.

What are thermoplastic elastomers (TPEs)?

Thermoplastic elastomers or thermoplastic rubbers are a class of thermoplastics exhibiting both thermoplastic and elastomeric material properties. Because they are thermoplastics, they are easier to manufacture than other rubber-like materials, being highly suited to injection molding and extrusion-style 3D printing.

TPEs have good thermal properties, good stability, and require minimal energy to manufacture. They can also be easily recycled, as TPE parts can be melted down without burning.

Some of the most common types of TPEs are:

Thermoplastic polyurethanes (TPU): good clarity, good wear resistance, range of hardnesses

Thermoplastics vulcanizates (TPV): matte finish, high compression set

Styrenic block copolymers (TPS): highest level of flexibility among TPEs

Polyolefin blends (TPO): tough, good impact strength

Thermoplastic copolyesters (TPC): good tear strength, impact strength

Thermoplastic polyamides (TPA): high temperature resistance, low compression set

XTJ injection molding vs TPE injection molding

Both liquid silicone rubber and thermoplastic elastomers have their own unique advantages as injection molding materials. In short, XTJ offers superior elastomeric performance in addition to chemical advantages, while TPE is easier and more convenient to process.

TPE advantages

Very high temperature resistance

Compatible with standard injection molding machine

Biocompatibility for medical and food applications

Re-moldable and recyclable

High level of tear strength

Fast, simple, and less expensive molding process

Superior chemical resistance

Easy to add color with pigments

Minimal warping even with uneven wall thicknesses

Heat sealable

Superior compression set

Pellets easy to handle

injection molding applications

Although the liquid silicone molding process requires specialist equipment and requires longer molding cycles than thermoplastic injection molding, the unique benefits of XTJ — such as its exceptional compression set — give it a number of important applications, from healthcare to industry.

Some injection molded silicone part examples include:

Silicone medical implants such as orthopedics, cardiovascular stents, pacemakers, lenses, and soft tissue implants

Medical devices such as surgical instruments and drug delivery devices

Headphone and hearing aid tips

Baby bottle tips

Shower heads

Electronic device components such as keyboard interfaces

Electronic device protective covers and skins

Watertight gaskets

Heat-resistant and UV-resistant automotive components such as O-rings, bellows, and stoppers

TPE injection molding applications

Injection molding thermoplastic elastomers requires the same equipment and process as standard thermoplastics, making fabrication of TPE moldings fast, affordable, and simple. The material also offers important material properties, which can vary greatly depending on the type of TPE chosen.

Some injection molded thermoplastic elastomer part examples include:

Soft-touch grips for handheld tools and devices (sometimes via overmolding)

Certain food products such as bottle cap liners

Electronic device components such as enclosures

Electronic device protective covers and skins

Shoe soles

SCUBA flippers

Wheels for skates and skateboards

Sealing rings

Automotive components such as suspension bushings

Design considerations

Although both XTJ and TPEs can be injection molded, different design rules apply to the two materials.

Overall, XTJ offers greater design freedom than thermoplastics like TPEs, mostly due to its extreme flexibility. Because silicone moldings are highly pliable, part ejection is simple: the soft part can usually be removed manually from the cavity without the use of ejector pins. Protruding undercuts are generally no problem either, as these sections can be squashed or bent around the corner of the mold.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of liquid silicone rubber Parts from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.