Table of Contents

Specifications:

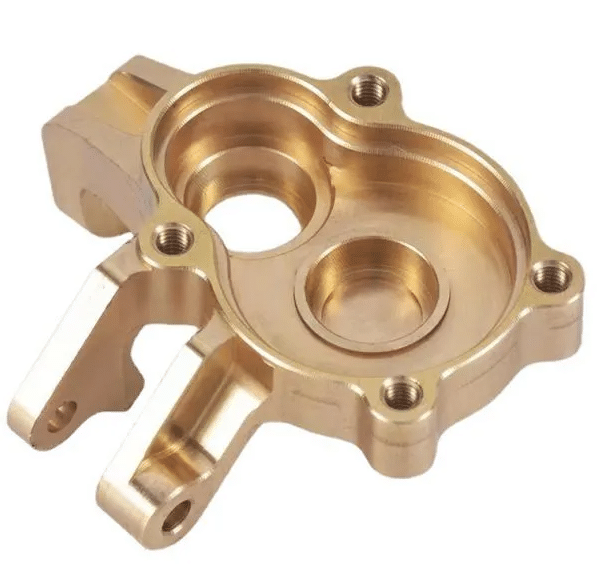

This Custom CNC Milling H96 Brass Components is a main part for papermaking equipment. When the equipment starts up, the part swings back and forth with an angle between 0°and 90°. Since it is usually used in a humid environment, so most of the Brass Components Manufacturer will choose for this Custom CNC Milling H96 Brass Components. Brass H98 is chosen because it is up to the plasticity required for this part, featuring higher strength, good electric conductivity, good thermal conductivity, good corrosion resistance in both the atmosphere and fresh water, good plasticity and ease for cold treatment.

Different Brass Grades And Purposes

Brass features high strength and hardness, good electric conductivity and thermal conductivity as well as good abrasive resistance and anti-attrition. After aging treatment, it shows significantly higher electric conductivity and thermal conductivity and ease for welding. Therefore, brass is widely applicable to motor commutators and electrodes used for spot welders and seam welders, as well as other parts with high requirements of strength, hardness, electric conductivity, and thermal conductivity. The electrode making electric sparks can be used to etch ideal mirror surfaces with good upright performances and the effects that are difficult to achieve with pure copper, such as slicing. It also does a good with the materials difficult to machine including tungsten steel.

Features Of H96 Brass

Composed of 96% copper and 4% zinc, the H96 brass features good cold and thermal machinability, applicable to various machining methods such as extruding, rolling, stamping, drawing, and forging, and easy to weld and tinplate. It has high corrosion resistance in both atmosphere and fresh water, without the tendency of stress-corrosion cracking. The H96 brass is usually used for coins, souvenirs, badges, detonators, shell cases, enamel blanks, waveguide tubes, radiating tubes/fins, and conductive devices.

Application Scope of CNC Milling Brass Parts

Because of the strong physical properties of copper, copper is not only used for production and processing, but also as a metal additive for smelting metals. It is a very powerful material. It is precisely because of this that copper is not only used for processing and manufacturing. So not only the processing and manufacturing industry likes copper very much, but many Brass Components Manufacturers also like copper very much.

In the transportation and ship industries, copper alloys are standard shipbuilding materials, including aluminium bronze, manganese bronze, aluminium brass, gunmetal (sn-zn bronze), cupronickel and nickel-copper alloy (Monel metal). In warships and merchant ships, copper and copper alloys are usually used for aluminium bronze propellers, bolts, condenser pipes, rives, and copperish cladding paints. In the auto industry, copper and copper alloys are usually used for radiators, brake pipelines, hydraulic devices, gears, bearings, power distribution and electrical power system, brake linings, gaskets as well as various connectors, accessories, and ornaments. The motors and commutators for railway trains as well as the control, brake, electrical and signal systems also depend on copper and copper alloys to function. In addition, the electrification of railways require a large amount of copper and copper alloys. The wiring and hydraulic, cooling and pneumatic systems require copper, aluminium bronze pipes are used for bearing cages and undercarriage bearings, and diamagnetic copper alloys are used for navigation instruments.

Machinery and metallurgical industry

In mechanical projects, a large amount of copper is used for the motors, circuits, and oil hydraulic, pneumatic circuit and control systems, and various driving parts and fixing parts, such as cylinder sleeves, connectors, fasteners, gears and twisting parts, all require copper and copper alloys for anti-attrition and lubrication. In the continuous casting technology, the key part – crystallizers – used for metallurgical equipment are mostly made of copper alloys with high strength and high thermal conductivity, such as chromium copper and silver-copper alloy. In electrometallurgy, vacuum arc furnaces and the water-cooled crucibles for electroslag furnaces are both made of copper pipes, all kinds of induction coils for induction heating are made by winding of the copper pipes or special shape copper pipes and cooling with watering within. As an alloy addition, copper is an important adding element in iron, steel and aluminum alloys. So many Brass Components Manufacturers will be adding a small amount of copper into the low-alloy structural steel can further improve its corrosion resistance.

Applications in the light industry

Copper and copper alloys can be used to manufacture the heat exchangers for air conditioning, clock and watch movements, screen cloth for paper machines, rollers, printing copperplates, fermentation cylinder linings, distillatory kettles, and architectural ornament components. I believe that many Brass Components Manufacturers are very accustomed to processing watch movements, watch straps, etc.

Emerging Industries And High-Tech Fields

Copper is also applicable to emerging industries and high-tech fields, such as superconducting alloy sheaths, ultralow temperature containers and pipes, cooling linings for rocket engines, magnet windings for high-energy accelerators.Like this Custom CNC Milling H96 Brass Components made of copper CNC milling, it is suitable for humid environments, and there are many high-tech industries that are applied in humid environments.

Finally, let’s quote a sentence from one of our customers: XTJ is a Custom CNC Milling H96 Brass Components company that always provides rapid quotes, on-time delivery, high quality, good coordination after equipping, and smooth processes even though we give them a lot of product drawings. In a word, XTJ is an excellent precision custom CNC milling parts manufacturer.

XTJ also has the required production capacity to handle various requirements across the world. This is because our factory has different sections to handle various types of CNC machining partsthat are demanded by our customers. Let us briefly list down the various facilities that we have for catering to the ever-growing demand of our customers.

Our full fledged workshop is spread over a wide area. It is capable of handling various types of processes. They include taking care of shenzhen Wire Machine, hand grinding machine, surface polishing machine, high speed punching machine, electric punching machine, etc. We have the right capacity to cater to the increasing needs of our clients.

XTJ also has a modern machining workshop with a good capacity for machining various types of machines including boring, drilling, milling, cutting and tapping units. We make use of modern dual axis, three axis and single axis machining techniques. We can handle the minutest machining needs of our clients up to +/- 0.001 mm.

As mentioned earlier above, our electroplating factory is huge and is perhaps one of the biggest in the country. We have incorporated the most modern technology that takes care of various types of electroplating including silver plating, nickel plating, gold plating and palladium plating. We also can offer the best of thick gold treatment, apart from high quality heavy metal treatment.

Further, we also have the best as far as quality testing processes and procedures are concerned. We have a wide range of quality testing equipment that is known for their accuracy and top class precision. Our quality lab can handle large volumes without compromising on the quality of testing under any circumstances.

Our Advantages

There are many reasons why dozens of small, big and large sized companies from across various industries have reposed their faith on XTJ for all their CNC Machine manufacturing and other allied services. We offer some obvious advantages and benefits that are quite obvious and irrefutable:

- CNC

- We have a good track record as far as our products, spare parts and other such allied products are concerned. We have catered to some of the big names across the world. These companies are known for their strictest standards as far as quality, and product specifications are concerned.

- We also offer top class after sales services and also provide the required counseling and guidance before our clients choose our products. We offer both online and on-site services. This makes us stand apart from the rest of the crowd.

- Our rates and prices are competitive without compromising on quality.

- We have the right factories, R&D labs, experienced and qualified staff to handle all types of needs of our customers.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.