EPDM and silicone are two commonly used rubbers in industrial applications, with silicone acting as a general use rubber while EPDM is more specialized. Here, we’ll be covering the basics of what EPDM and silicone rubber are, as well as their similarities and differences, to help you get a better grasp of which rubber works better for certain applications.

What is EPDM?

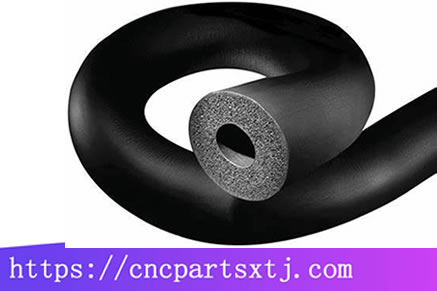

EPDM (Ethylene Propylene Diene Monomer) rubber is a popular choice for outdoor and harsh environment applications, thanks to its resistance to water, heat and cold, weather, ozone, UV rays, steam, electricity, and abrasion. EPDM is made up of a single bond, chemically saturated backbone of polymethylene. This material’s flaws lay in its inability to resist oil, grease, hydrocarbon fuel, concentrated acid, and halogenated solvent. EPDM is typically used in roofing, plumbing, HVAC, and automotive applications.

What is Silicone?

Silicone, also known as polysiloxane, is best known for its flexibility and temperature resistance. However, it’s also flame-resistant, hypoallergenic, gas permeable, chemically inert, and nonstick. Silicone rubber is an elastomer, an elastic polymer with an inorganic silicon-oxygen backbone attached to organic molecules. It’s manufactured by extracting silicon from silica, then passing it through hydrocarbons and mixing the resulting material with chemicals to create silicone rubber.

Silicone is not, however, resistant to steam, hydrocarbon fuel, alkali, acid, trichloroethylene, or aromatic hydrocarbons. The material is generally found in electronics, industrial, aerospace, construction, automotive, medical, consumer product, and HVAC applications.

What’s the Difference Between EPDM and Silicone?

Both EPDM and silicone are synthetic rubbers, but their key differences are in the width of their applications: silicone is better for more general uses, while EPDM is geared toward more specific purposes. Both rubbers have electricity, weather, ozone, and UV resistance, as well as good bonding with metal.

Silicone is more flexible in its applications, but it’s also more expensive. The material is able to function under much higher temperatures than EPDM, with a range of about 150 degrees F more at 446 F (230 C), while still being able to function at the same minimum temperatures of around -58 degrees F (-50 degrees C). Silicone is also commonly used for food safe uses, while EPDM is unsafe for those applications. Additionally, automotive fluids that would break EPDM down are not an issue for silicone, and it has a better compression set and longer lifespan.

EPDM, on the other hand, is a more specialized rubber that costs less and performs better under specific applications. Although both rubbers are considered waterproof, silicone swells when exposed to water, while EPDM stays constant. It’s also more resistant to steam, being able to function in steam up to 392 degrees F (200 C) without air, while silicone can only function up to 249 degrees F (121 C). EPDM also shows more abrasion and weather resistance than silicone rubber while exhibiting nearly three times the tensile strength of silicone at 14 MPa.

Conclusion

Both EPDM and silicone have their merits and drawbacks, depending on the application they’re used for. If you’d like more information on these and other types of rubber, you can check out our buyer’s guide to the various types of industrial rubber. If you’re more interested in sourcing, we can help with that too. Our Supplier Discovery page can guide you to more than 170 EPDM suppliers and 120 silicone suppliers.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of EPDM Parts from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.