Table of Contents

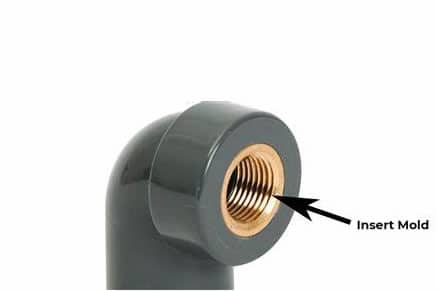

What is Insert Molding?

Insert molding is a specialized manufacturing process that involves incorporating pre-formed components, known as inserts, into a mold cavity before the injection molding process. The material used in insert molding can vary, ranging from thermoplastics and thermosetting polymers to metal inserts. This technique allows for the creation of components with intricate geometries and ensures a reliable connection between dissimilar materials. The insert molding industry encompasses various sectors, including: automotive, electronics, medical devices, and consumer goods. It plays a crucial role in achieving cost-effective, efficient, and high-quality manufacturing across diverse industries.

This article will discuss what insert molding is, its process, the materials used, and the industries that benefit from it.

Insert molding is a manufacturing process that involves placing prefabricated components, known as inserts, into a mold before injecting molten material, typically a thermoplastic or thermosetting polymer, to form a cohesive, integrated product. This process allows for the seamless integration of diverse materials and components, resulting in products with enhanced functionality and structural integrity.

Why Should You Consider Insert Molding?

Insert molding offers manufacturers several advantages, making it a preferred choice for production. This process allows for the integration of prefabricated components, known as inserts, into the molding process. Insert molding creates products with enhanced structural integrity by securely bonding inserts with the surrounding material. This results in robust and durable components. This reliability is essential for applications in which the integrity of the product is paramount, such as in medical devices. The process reduces assembly steps, reducing the overall production time and leading to cost savings. Manufacturers can streamline production by incorporating multiple materials in a single step. This efficiency is critical for meeting tight deadlines and increasing throughput. Insert molding is ideal for manufacturing complex and intricate parts with varying shapes and sizes. This versatility is particularly beneficial in industries in which precision is crucial. The technique allows for innovative design possibilities that might be challenging with traditional molding methods. Manufacturers can combine different materials within a single product, optimizing material properties for specific functions. This flexibility is valuable in industries like automotive and electronics.

How Does Insert Molding Work?

In insert molding, the molten material goes into the mold at high pressure, allowing it to flow around the inserts and fill intricate details of the mold. This process ensures that the molten material encapsulates the inserts, creating a solid and cohesive bond during the cooling and solidification phase.

Insert molding is favored for its ability to produce complex parts with multiple materials in a single manufacturing step. The process reduces the need for additional assembly and machining steps, contributing to cost efficiency and faster production cycles.

What Is the Insert Molding Process?

The insert molding process entails several sequential steps to integrate prefabricated inserts with molten material as listed below:

Carefully position prefabricated inserts into the mold, considering their intended locations within the final product.

Securely close the mold to hold the inserts in place and create a cavity for the molten material.

Introduce molten material into the mold at high pressure, allowing it to flow around the inserts and fill the mold cavity.

Allow the injected material to cool and solidify, ensuring proper adhesion to the inserts and the formation of a cohesive final product.

Open the mold once the material has solidified, revealing the integrated product with the securely bonded inserts.

Safely eject the finished product from the mold for further processing or quality control.

Which Type of Industry Uses Insert Molding?

Insert molding is utilized across various industries, with a significant presence in sectors that benefit from the integration of prefabricated components and diverse materials. Industries commonly employing insert molding include:

Automotive

Electronics and Electrical

Medical devices

Consumer goods

Industrial equipment manufacturing

When Is Insert Molding Necessary?

Insert molding is necessary when the specific requirements of a manufacturing project demand the following: the integration of prefabricated components, multi-material combinations, enhanced structural integrity, reduced assembly steps, improved production efficiency, design flexibility, reliable connections, and cost-effective production. It is a versatile solution that addresses various challenges across different industries.

What Are the Advantages of Insert Molding?

The following are some advantages of insert molding:

Creates products with superior structural integrity by securely bonding inserts with the surrounding material.

Reduces assembly steps, leading to cost savings by incorporating multiple materials in a single step.

Ideal for manufacturing complex and intricate parts with varying shapes and sizes, offering design flexibility.

Enables the combination of different materials within a single product, optimizing material properties for specific functions.

Often eliminates the need for additional machining or assembly steps, reducing overall production time.

Enables the use of specific materials in designated areas, optimizing material performance based on functional requirements.

Allows for the creation of lightweight components by strategically placing inserts only where needed.

Provides a high level of consistency and repeatability in the manufacturing process, leading to uniform product quality.

What Are the Disadvantages of Insert Molding?

Insert molding, while offering various advantages, also comes with some disadvantages. Here are key disadvantages associated with insert molding:

The tooling required for insert molding can have higher initial costs compared to other molding processes. The molds used in insert molding can be complex, especially when accommodating intricate insert designs.

The range of materials suitable for insert molding may be more limited compared to some other molding processes. Certain materials may not be conducive to the high temperatures and pressures involved in the insert molding process, restricting material options.

The cycle time for insert molding can be longer compared to traditional injection molding. The process may require additional time for proper insert placement, and cooling times can be critical, affecting overall production speed.

Precise placement of inserts within the mold can be challenging, affecting the quality of the final product. Ensuring accurate and consistent placement of inserts requires careful attention and may involve additional steps in the manufacturing process.

There is a risk of inserts shifting during the molding process, leading to misalignment or defects.

May be less suitable for high-volume production due to cycle time considerations and the intricacies of the process.

Quality control in insert molding can be more complex, especially when inspecting the integration of inserts with the molded material. Detecting defects or inconsistencies in the bonding between inserts and the surrounding material may require advanced inspection methods.

What Type of Materials Are Used for Insert Molding?

Insert molding involves using a variety of materials, both for the prefabricated inserts and the molten material injected into the mold. Here is a list of materials commonly used in insert molding:

Thermoplastics, including: polyethylene, polypropylene, ABS (acrylonitrile butadiene styrene), and polycarbonate.

Thermosetting polymers, like: epoxy, phenolic, and melamine.

Metals, such as: aluminum, brass, and stainless steel.

Elastomers materials like silicone and rubber.

Engineered resins, including PEEK (polyether ether ketone) and PPS (polyphenylene sulfide).

Composite materials, such as glass-filled or carbon-filled polymers.

Ceramics.

Conductive and insulating materials, such as conductive plastics or insulating polymers.

Biocompatible materials, such as medical-grade polymers .

What Products Can Be Manufactured From Insert Molding?

Insert molding is a versatile manufacturing process that can be employed to create a wide range of products across various industries. In the automotive industry, insert molding is extensively used to produce components (e.g., connectors, sensors, dashboard components, and interior trim pieces) that require a combination of materials and intricate designs. It enhances the durability and functionality of parts used in vehicles. Electronics benefit from insert molding for the encapsulation of delicate components, embedding connectors, and creating durable housings. The process ensures reliable electrical connections and protects sensitive electronics. Insert molding is crucial in the medical industry for manufacturing components that require precision, reliability, and biocompatibility. It is used to create complex and reliable parts for various medical applications. Examples include: catheter components, connectors for medical devices, and housings for diagnostic equipment.

The manufacturing timeline for insert molding can vary based on factors such as: product complexity, material types, and production volume. Designing the mold and prototyping may take weeks to months, depending on complexity. Creating the mold can take several weeks. Insert placement and injection molding may take minutes to hours per cycle. Cooling and solidification only take a few minutes, as do mold opening and ejection. Finally, quality-control inspections and post-processing steps (such as trimming or finishing) could take days.

The volume of manufacturing is influenced by factors like: market demand, product complexity, and the efficiency of the insert molding process. Manufacturers can adapt the process to meet the specific production requirements of different industries and products. The volume of manufacturing can range from small batches to large-scale production. Small batches or limited production runs are common for specialized or niche products. This allows for flexibility in design changes and customization. For products with high demand, like consumer electronics components, insert molding can be scaled up to accommodate large production volumes. High-volume manufacturing often involves automated processes to increase efficiency.

What Are the Different Types of Molding Processes?

There are various molding processes used in manufacturing to shape materials into specific forms. Here are the different types of molding processes:

Injection Molding: It involves injecting molten material into a mold cavity, where it solidifies to create a finished product. This process is widely used for producing plastic and some metal components.

Blow Molding: This is a manufacturing process in which a hollow object is formed by inflating a heated plastic tube inside a mold. It is mostly used for producing containers like bottles and containers.

Compression Molding: This involves putting material into an open mold, and then closing it. You heat it and press down to squeeze the material into shape. It’s good for making big parts with complicated designs.

Rotational Molding (Rotomolding): This is a method in which a heated hollow mold is rotated around two perpendicular axes, causing the material to disperse and coat the inside of the mold. It is mostly used for producing large, seamless, and hollow parts.

Transfer Molding: Transfer molding is a hybrid process combining compression and injection molding elements. It involves transferring a pre-measured amount of material into a heated mold cavity in which it is compressed.

Thermoforming: Thermoforming is a process in which a flat sheet of plastic is heated and formed into a three-dimensional shape using a mold. It is used for producing packaging materials, trays, and disposable items.

Extrusion Molding: This involves forcing molten material through a shaped die to produce a continuous profile. This method is commonly used for creating products with a consistent cross-section, such as: pipes, tubing, and sheets.

Injection Blow Molding: This is a two-stage process that begins with the injection molding of a preform. The preform is then transferred to a blow mold, in which it is inflated to its final shape. This process is often used for producing bottles.

Reaction Injection Molding (RIM): It involves the mixing of two liquid components that react and solidify in a mold. This process is often used for producing large, lightweight, and complex parts with polyurethane materials.

Low-Pressure Molding: This involves applying low pressure to encapsulate and protect electronic components or other delicate items with thermoplastic materials. It is suitable for sensitive applications.

Where To Look for Insert Molding Services?

There are various places in which one can find reliable insert molding services. Online directories such as XTJ Machining, or industry-specific platforms provide a comprehensive list of molding service providers. Browse through these directories, filtering results based on location, capabilities, and industry expertise. Attend industry-specific trade shows and exhibitions at which molding service providers showcase their capabilities. Online platforms like LinkedIn or dedicated industry forums can be valuable for gathering insights and recommendations. Check local manufacturing directories or business directories in your region. These directories often list companies offering manufacturing services, including insert molding.

How Can XTJ Machining Help You Find Insert Molding Suppliers?

XTJ Machining is a comprehensive platform that facilitates the efficient discovery of insert molding suppliers. XTJ Machining allows users to perform highly specific searches based on product categories, capabilities, location, and certifications. For insert molding, you can filter suppliers who specialize in this process. XTJ Machining provides comprehensive supplier profiles with information about their capabilities, certifications, facilities, and more. This allows you to assess suppliers and make informed decisions based on your specific requirements. Access supplier product catalogs on XTJ Machining to understand the range of insert molding products and capabilities offered by each supplier. XTJ Machining enables users to request instant or custom quotes from multiple insert molding suppliers. This feature streamlines the quote comparison process, helping you make informed decisions. Stay informed about industry trends and insights available on XTJ Machining, assisting you in making strategic decisions regarding insert molding suppliers. Since XTJ Machining is now operated by Xometry, users can benefit from secure buying and selling through Xometry’s payment terms and transaction assurance, ensuring a reliable and secure transaction process.

Is Insert Molding Better Than Overmolding?

It depends. The choice between insert molding and overmolding depends on the application requirement, the desired product characteristics, and the manufacturing objectives.

If the application demands a distinct boundary between materials, insert molding might be preferred. For a seamless transition, overmolding is suitable. If combining different materials is a priority, insert molding may be the choice. Overmolding is more about enhancing a primary material. For intricate designs and multi-material components, insert molding may be advantageous. Overmolding is often used for simpler designs with additional surface features. Car manufacturers use both insert molding and overmolding, depending on what the part needs. Overmolding is often used for aesthetic and ergonomic enhancements, while insert molding may be preferred for complex electronic components.

To learn more, see our full guide on Insert Molding vs. Overmolding.

What Is the Difference Between Insert Molding and Traditional Injection Molding?

Insert molding differs from traditional injection molding by incorporating prefabricated inserts into the process, allowing for the integration of diverse materials in a single step.

Insert molding involves placing prefabricated inserts into the mold before injecting molten material. The molten material surrounds and bonds with the inserts during the molding process. It enables the incorporation of diverse materials and prefabricated components in a single manufacturing step, reducing assembly needs. It is commonly used for creating complex parts in industries like automotive and electronics.

The injection molding procedure involves injecting molten material into a closed mold under high pressure. It is ideal for high-volume production, precise and detailed parts, and rapid manufacturing. It is widely used in industries like electronics and consumer goods for producing intricate and small to medium-sized parts.

Both processes involve injecting molten material into a mold to create a final product. Both processes utilize molds made of metal, and the basic principles of molding, such as cooling and solidification, are similar.